Bilge Stripping Sandpaper Grit?

Moderators: CaptPatrick, mike ohlstein, Bruce

- JohnV8r

- Senior Member

- Posts: 625

- Joined: Jun 29th, '06, 21:59

- Location: Northern California Bay Area

- Contact:

Bilge Stripping Sandpaper Grit?

Hey Guys,

When I have the engines out and I am stripping the grey bilgecote paint off (pre-fairing) the engine compartment and bilge, what sandpaper grit should I use?

Also, what grit sandpaper do I need to sand through to prep the engine compartments and bilge for new paint?

Thanks in advance!

When I have the engines out and I am stripping the grey bilgecote paint off (pre-fairing) the engine compartment and bilge, what sandpaper grit should I use?

Also, what grit sandpaper do I need to sand through to prep the engine compartments and bilge for new paint?

Thanks in advance!

Bertram 31 - The Best Boat Ever Built

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

Re: Bilge Stripping Sandpaper Grit?

Start with any grit you want, but 320 is the finest that you'll need for the bilge. I'd probably stop at 220 just to have more tooth for the paint to stick to...

Br,

Patrick

Molon labe

Patrick

Molon labe

- JohnV8r

- Senior Member

- Posts: 625

- Joined: Jun 29th, '06, 21:59

- Location: Northern California Bay Area

- Contact:

Re: Bilge Stripping Sandpaper Grit?

Perfect! I want to order the sandpaper ahead of time so I can get better sandpaper at a bulk price.

Thanks Patrick

Thanks Patrick

Bertram 31 - The Best Boat Ever Built

Re: Bilge Stripping Sandpaper Grit?

Anytime Im strip sanding, I always begin with using the most aggressive paper I have available, and go progressively finer from there.

One thing to consider is that the heavy woven roving substrate your working on is a very uneven surface. If you plan on strip sanding all of the bilgekote off, you'll be removing a good bit of glass as well so you'll want to dress/protect yourself appropriately.

If you plan on strip sanding the paint off the top of the weave only, and using the filler / fairing compound to fill in all the low spots in the weave, then the filler will be adhering to the paint and its bond will only be as good as the bilgekotes bond to the hull… which may be ok?

I think I'd go the first route and start with a clean palette though… I'd do it as follows:

Strip sand the bilge with 36/40 grit until the the hi weave is bare and knocked down enough that the depressions are beginning to get hit with the grit as well.

Switch up to 80grit to smooov out the aggressive 40 grit swirls, and to remove the remaining coating.

Vacuum and solvent clean.

Mix up your first batch of fairing compound / filler and drag it over all your specified surface, let her kick.

Sand the filler application quickly with 80, then switch to 120.

Vac and solvent clean.

Determine where you need additional filler, mix and apply it.

Sand with 120, then sand the entire area with 220.

Vac, solvent clean and proceed with primer & paint.

One thing to consider is that the heavy woven roving substrate your working on is a very uneven surface. If you plan on strip sanding all of the bilgekote off, you'll be removing a good bit of glass as well so you'll want to dress/protect yourself appropriately.

If you plan on strip sanding the paint off the top of the weave only, and using the filler / fairing compound to fill in all the low spots in the weave, then the filler will be adhering to the paint and its bond will only be as good as the bilgekotes bond to the hull… which may be ok?

I think I'd go the first route and start with a clean palette though… I'd do it as follows:

Strip sand the bilge with 36/40 grit until the the hi weave is bare and knocked down enough that the depressions are beginning to get hit with the grit as well.

Switch up to 80grit to smooov out the aggressive 40 grit swirls, and to remove the remaining coating.

Vacuum and solvent clean.

Mix up your first batch of fairing compound / filler and drag it over all your specified surface, let her kick.

Sand the filler application quickly with 80, then switch to 120.

Vac and solvent clean.

Determine where you need additional filler, mix and apply it.

Sand with 120, then sand the entire area with 220.

Vac, solvent clean and proceed with primer & paint.

I don't know what the world may want,

But a good stiff drink it surely dont,

Think I'll go and fix myself...a tall one.

But a good stiff drink it surely dont,

Think I'll go and fix myself...a tall one.

- JohnV8r

- Senior Member

- Posts: 625

- Joined: Jun 29th, '06, 21:59

- Location: Northern California Bay Area

- Contact:

Re: Bilge Stripping Sandpaper Grit?

Buju,

Thanks for the detail. Most of my background with stripping/sanding is with wood. I have two quick questions that relate to stripping/sanding a material over fiberglass:

1. I am primarily a West System Epoxy guy because it is easy for me to get out here. To fair the inner hull surface prior to painting, can I use a light weight filler like West System 410 Microlight filler or do I need a filler with more density/microballoons like 407 Low Density filler or even 404 High Density? Alternatively, is there a fairing/filler material that I should be using to fair the inside of the hull that is not an epoxy based material?

2. Denatured alcohol, turpentine, or mineral spirits as the solvent wash between sandings?

Thanks for the help!

John

Thanks for the detail. Most of my background with stripping/sanding is with wood. I have two quick questions that relate to stripping/sanding a material over fiberglass:

1. I am primarily a West System Epoxy guy because it is easy for me to get out here. To fair the inner hull surface prior to painting, can I use a light weight filler like West System 410 Microlight filler or do I need a filler with more density/microballoons like 407 Low Density filler or even 404 High Density? Alternatively, is there a fairing/filler material that I should be using to fair the inside of the hull that is not an epoxy based material?

2. Denatured alcohol, turpentine, or mineral spirits as the solvent wash between sandings?

Thanks for the help!

John

Last edited by JohnV8r on Feb 15th, '14, 14:27, edited 1 time in total.

Bertram 31 - The Best Boat Ever Built

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

Re: Bilge Stripping Sandpaper Grit?

I'd go with the 407 low density mixed with some 406 colloidal silica for fairing. Denatured alcohol will react slightly with any epoxy surface, but turpintine or mineral spirits could hamper any epoxy bonding in subsequent layers. Stick to the alcohol...

Still, you just can't beat AwlFair for fairing & and it's an epoxy.

Still, you just can't beat AwlFair for fairing & and it's an epoxy.

Br,

Patrick

Molon labe

Patrick

Molon labe

- JohnV8r

- Senior Member

- Posts: 625

- Joined: Jun 29th, '06, 21:59

- Location: Northern California Bay Area

- Contact:

Re: Bilge Stripping Sandpaper Grit?

Thanks Patrick! 50/50 mix, 75 Microlight/25 Colloidal Silica? What percentage mixture would you recommend?

Bertram 31 - The Best Boat Ever Built

Re: Bilge Stripping Sandpaper Grit?

The microspheres in the epoxy work fine. The microspheres are porous, but properly primed and topcoated, your good.

But it's major overkill, no reason to spend that much on epoxy just to smooov out your bilge.

Although I use epoxy for everything too, so yeah, I get it.

Could do it with a poly or vinylester filler for much less expense.

Look into AdTec p17 or p77... One of them has a much longer working time, which is great when doing large areas.

3m has a few easier sanding marine ester fillers as well.

Turp and min.spirits have no place in your boat. They're for house work.

Denatured is your ticket. Acetone works as well.

But it's major overkill, no reason to spend that much on epoxy just to smooov out your bilge.

Although I use epoxy for everything too, so yeah, I get it.

Could do it with a poly or vinylester filler for much less expense.

Look into AdTec p17 or p77... One of them has a much longer working time, which is great when doing large areas.

3m has a few easier sanding marine ester fillers as well.

Turp and min.spirits have no place in your boat. They're for house work.

Denatured is your ticket. Acetone works as well.

I don't know what the world may want,

But a good stiff drink it surely dont,

Think I'll go and fix myself...a tall one.

But a good stiff drink it surely dont,

Think I'll go and fix myself...a tall one.

Re: Bilge Stripping Sandpaper Grit?

Did it again.

I don't know what the world may want,

But a good stiff drink it surely dont,

Think I'll go and fix myself...a tall one.

But a good stiff drink it surely dont,

Think I'll go and fix myself...a tall one.

Re: Bilge Stripping Sandpaper Grit?

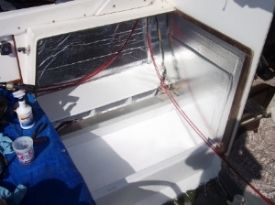

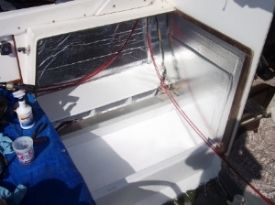

I used a flap wheel to do the green square you see in this photo. I had to sand pretty deep into the woven roving to get the bilgekote paint out of the depressions like already mentioned. I could not fathom the thought of doing the whole hatch. You have to be careful anywhere there is plywood under the glass as well. Goes through quick if you are not dainty with the grinder. The glass is super thick in the bottom of the bilge though so that should be easier.

Re: Bilge Stripping Sandpaper Grit?

Yeah, its a serious P.I.T.A to sand down that weave. About on par with sanding off bottom paint.

John, consider if you would, using Peel Away stripper to remove your bilge paint instead of strip sanding.

Peel Away is unique in that you don't have to scrape or abrade the coating off like other chem strippers. You apply the stripper to the substrate, then cover it with a paper/membrane. Its got to sit for a specified amount of time, then you peel off the membrane, and the old coating comes off with it.

Yeah- that simple. Yeah, it does really work- at least it has in every application Ive used it for in the last couple decades.

No question Im using the Peel Away marine version the next time I need to remove bottom paint… no question.

http://www.paintremover.com/paint-remov ... boats.html

John, consider if you would, using Peel Away stripper to remove your bilge paint instead of strip sanding.

Peel Away is unique in that you don't have to scrape or abrade the coating off like other chem strippers. You apply the stripper to the substrate, then cover it with a paper/membrane. Its got to sit for a specified amount of time, then you peel off the membrane, and the old coating comes off with it.

Yeah- that simple. Yeah, it does really work- at least it has in every application Ive used it for in the last couple decades.

No question Im using the Peel Away marine version the next time I need to remove bottom paint… no question.

http://www.paintremover.com/paint-remov ... boats.html

I don't know what the world may want,

But a good stiff drink it surely dont,

Think I'll go and fix myself...a tall one.

But a good stiff drink it surely dont,

Think I'll go and fix myself...a tall one.

- JohnV8r

- Senior Member

- Posts: 625

- Joined: Jun 29th, '06, 21:59

- Location: Northern California Bay Area

- Contact:

Re: Bilge Stripping Sandpaper Grit?

Wow...just watched several videos on Peel Away. I think I'll order a gallon and give it a test on the bilge area under the salon floor. That area needs to be repainted as well.

Thanks for the tip Buju!

Thanks for the tip Buju!

Bertram 31 - The Best Boat Ever Built

- matt ciarpella

- Junior Member

- Posts: 112

- Joined: Jan 13th, '09, 19:22

- Location: Baltimore, Md

Re: Bilge Stripping Sandpaper Grit?

Buju, How many gals of Peel Away do you think it would take to strip a 31?

tks, Matt

tks, Matt

Re: Bilge Stripping Sandpaper Grit?

I used about 2 gallons of a similar product to remove about 95% of the multiple layers of bottom paint on my 25. Some of this was waste due to my inexperience. These strippers need time and moisture to work. I sealed small-ish treated areas with plastic wrap - tapped all around. I left these for a day to work their magic. The result was a big head start on the grinding process.

1963 Bertram 25

1973 Boston Whaler 13 - sold!

1998 Scout 172 SF - beach taxi

1973 Boston Whaler 13 - sold!

1998 Scout 172 SF - beach taxi

- TailhookTom

- Senior Member

- Posts: 985

- Joined: Jul 3rd, '06, 14:12

Re: Bilge Stripping Sandpaper Grit?

I'm with Kevin - I used my Metabo grinder - I'm not the patient type - it made short work of it. And I got three free, unplanned, spots that I didn't have to drill for transducers -- JK. Be careful, damn thing doesn't remove just bumps and ridges -- I have less skin and a good scar on my right hand to prove it.

Tom

Tom

Re: Bilge Stripping Sandpaper Grit?

I'm not really sure Matt, I haven't used it for bottom paint yet. I haven't used the Marine Peel Away at all, but I have used several of their other strippers and they all worked great in that particular application.

I'd think a 5gal kit would be sufficient or overkill, but Im not sure on what WFT it needs to go on at. Id contact them, generally very knowledgeable and ready to help.

Cam, there is no similar product.

I remember your were fighting against solvent evaporation on your stripper, where it'd dry up before you could scrape it. And not taking off enough layers. So you taped visqueen over areas to keep the solvent in and the stripper wet... which is a useful trick, but not the same thing.

IMO Peel Away is the CX of paint strippers... magic in a bucket... with a membrane.

I'd think a 5gal kit would be sufficient or overkill, but Im not sure on what WFT it needs to go on at. Id contact them, generally very knowledgeable and ready to help.

Cam, there is no similar product.

I remember your were fighting against solvent evaporation on your stripper, where it'd dry up before you could scrape it. And not taking off enough layers. So you taped visqueen over areas to keep the solvent in and the stripper wet... which is a useful trick, but not the same thing.

IMO Peel Away is the CX of paint strippers... magic in a bucket... with a membrane.

I don't know what the world may want,

But a good stiff drink it surely dont,

Think I'll go and fix myself...a tall one.

But a good stiff drink it surely dont,

Think I'll go and fix myself...a tall one.

- matt ciarpella

- Junior Member

- Posts: 112

- Joined: Jan 13th, '09, 19:22

- Location: Baltimore, Md

Re: Bilge Stripping Sandpaper Grit?

Thanks, I was wondering if 5 gal would do it. I'll give them a call

Re: Bilge Stripping Sandpaper Grit?

I have always used a 4" angle grinder, 36 and 80 grit discs with a tyvek suit and respirator.

End result is not baby ass smooth but close enough for the bilge.

End result is not baby ass smooth but close enough for the bilge.

Who is online

Users browsing this forum: Bing [Bot], Google [Bot] and 57 guests