Bertram 25 conversion to an outboard powered CC

Moderators: CaptPatrick, mike ohlstein, Bruce

Bertram 25 conversion to an outboard powered CC

Hi All,

I'm rehabbing my Bertram 25 and have had a couple of threads on various topics and wanted to put them under one so there was only one thread to update. This spring and summer should see a lot of progress as a lot of the bits and pieces start to come together.

I am converting my 1964 moppie to a center console with a single 300 outboard.

Here are some of the other threads I've started on this

Top Cap modification - This thread shows how I've made the cabin a bit smaller to make more deck space - http://bertram31.com/newbb/viewtopic.php?f=2&t=13701

Motor Well Idea - This thread I am trying to figure out how I want to hang the outboard - http://bertram31.com/newbb/viewtopic.php?f=2&t=14025

Issues with Stringers - This thread is my discovery of port side stringer issues as well as the work to repair / reinforce them. http://bertram31.com/newbb/viewtopic.php?f=2&t=13688

Filling the Transom - Replacing Transom Core and prepping for an outboard - http://bertram31.com/newbb/viewtopic.php?f=2&t=13707

I'm rehabbing my Bertram 25 and have had a couple of threads on various topics and wanted to put them under one so there was only one thread to update. This spring and summer should see a lot of progress as a lot of the bits and pieces start to come together.

I am converting my 1964 moppie to a center console with a single 300 outboard.

Here are some of the other threads I've started on this

Top Cap modification - This thread shows how I've made the cabin a bit smaller to make more deck space - http://bertram31.com/newbb/viewtopic.php?f=2&t=13701

Motor Well Idea - This thread I am trying to figure out how I want to hang the outboard - http://bertram31.com/newbb/viewtopic.php?f=2&t=14025

Issues with Stringers - This thread is my discovery of port side stringer issues as well as the work to repair / reinforce them. http://bertram31.com/newbb/viewtopic.php?f=2&t=13688

Filling the Transom - Replacing Transom Core and prepping for an outboard - http://bertram31.com/newbb/viewtopic.php?f=2&t=13707

Re: Bertram 25 conversion to an outboard powered CC

today's activity 1, making a new cabin floor panel

When I cut the cabin down 22" I cut half way through the small hatch in the cabin floor. There were also cut outs where the original marine head hoses were installed. Years ago I removed the head and glassed in the through hulls which were under the cabin floor hatch.

Before Starting

https://photos.app.goo.gl/9FFPAdj7ZSAoALP9A

Panel cut out and test fit

https://photos.app.goo.gl/imsk7RsL53JjNMb78

I cut down the panel which covered the head. This will have to be good enough for this year, maybe next year I will make the hatch covering the head smaller to allow for more floor space

https://photos.app.goo.gl/BztMaRRmy5H7R41Q8

When I cut the cabin down 22" I cut half way through the small hatch in the cabin floor. There were also cut outs where the original marine head hoses were installed. Years ago I removed the head and glassed in the through hulls which were under the cabin floor hatch.

Before Starting

https://photos.app.goo.gl/9FFPAdj7ZSAoALP9A

Panel cut out and test fit

https://photos.app.goo.gl/imsk7RsL53JjNMb78

I cut down the panel which covered the head. This will have to be good enough for this year, maybe next year I will make the hatch covering the head smaller to allow for more floor space

https://photos.app.goo.gl/BztMaRRmy5H7R41Q8

Re: Bertram 25 conversion to an outboard powered CC

today's activity #2 - Hatch for the oversized fishboxes I am creating.

Years ago I traded board member CMP 2 of the cast bronze vents I wasn't using for his fuel tank hatches. When I removed the deck I saved the fuel tank hatch frame thinking that I could cut it down and reuse it with CMP's hatch.

1/2 Hatch sitting in full sized hatch frame

https://photos.app.goo.gl/Fg2h6voL2jw9KML89

Since the 1/2 hatch had 1 side with curved corners and the other with right angle corners I had to fabricate the right angle corners. I put the hatch in the full frame, made marks leaving myself 3/8" extra space then made 45 degree angle cuts. I was hoping to use the excess from each of the sides as there was more than enough material but the 45 cut was the wrong side and I ended up using the end making a straight cut on one side and a 45 degree cut on the other side. I removed all the coring material from the back side as it was all wet and started to prep to glass it back together. I will need to glass it back together in 3 places as shown with the green glass.

https://photos.app.goo.gl/VJo3jKvi66xXL6TTA

Test fit all together

https://photos.app.goo.gl/nHnDNjnFNt62cz8j9

My thoughts are to use the hatch to keep the hatch frame straight when glassing together, I'll cover the areas being bonded with packing tape then clamp the hatch to the frame and make the spacing right then glass the bottom. Once it is holding shape, I will glass the inside.

Overall the material will be about 3/8" thick and the 2 sides will sit over the stringers so it will be fairly easy to cut a hole in the new nida-core deck, remove 3/8" from the height where the hatch frame will sit then glass it all together from the top. My buddy has had good luck using a similar technique in his Seacraft project

https://photos.app.goo.gl/y8Y6XtSWd5etYo3x5

Years ago I traded board member CMP 2 of the cast bronze vents I wasn't using for his fuel tank hatches. When I removed the deck I saved the fuel tank hatch frame thinking that I could cut it down and reuse it with CMP's hatch.

1/2 Hatch sitting in full sized hatch frame

https://photos.app.goo.gl/Fg2h6voL2jw9KML89

Since the 1/2 hatch had 1 side with curved corners and the other with right angle corners I had to fabricate the right angle corners. I put the hatch in the full frame, made marks leaving myself 3/8" extra space then made 45 degree angle cuts. I was hoping to use the excess from each of the sides as there was more than enough material but the 45 cut was the wrong side and I ended up using the end making a straight cut on one side and a 45 degree cut on the other side. I removed all the coring material from the back side as it was all wet and started to prep to glass it back together. I will need to glass it back together in 3 places as shown with the green glass.

https://photos.app.goo.gl/VJo3jKvi66xXL6TTA

Test fit all together

https://photos.app.goo.gl/nHnDNjnFNt62cz8j9

My thoughts are to use the hatch to keep the hatch frame straight when glassing together, I'll cover the areas being bonded with packing tape then clamp the hatch to the frame and make the spacing right then glass the bottom. Once it is holding shape, I will glass the inside.

Overall the material will be about 3/8" thick and the 2 sides will sit over the stringers so it will be fairly easy to cut a hole in the new nida-core deck, remove 3/8" from the height where the hatch frame will sit then glass it all together from the top. My buddy has had good luck using a similar technique in his Seacraft project

https://photos.app.goo.gl/y8Y6XtSWd5etYo3x5

Re: Bertram 25 conversion to an outboard powered CC

No pics from Saturday's fun, I sanded down 3" on either side of where the bulkheads were going to go then glassed one side on the fishbox bulkheads with 2 layers of 6" wide 1708.

I also glassed the fuel tank hatch frame together, I had a heck of a time getting it all aligned up and in the end one of the clamps slipped so I'll have to cut one of the 3 joints and re-do it as the pieces became 1/4" out of alignment. If I were to do it again and I will on the joint which was messed up, I would have drilled holes and screwed the pieces together onto a board so they couldn't move.

my kids went crazy saturday afternoon and my wife would have killed me if I left her alone sunday so we spent the day together and I didn't get anything done.

I also glassed the fuel tank hatch frame together, I had a heck of a time getting it all aligned up and in the end one of the clamps slipped so I'll have to cut one of the 3 joints and re-do it as the pieces became 1/4" out of alignment. If I were to do it again and I will on the joint which was messed up, I would have drilled holes and screwed the pieces together onto a board so they couldn't move.

my kids went crazy saturday afternoon and my wife would have killed me if I left her alone sunday so we spent the day together and I didn't get anything done.

Re: Bertram 25 conversion to an outboard powered CC

I took a 1/2 day off on Friday and got into sanding the fishbox area to put down one more layer of 1708 to cover everything up, on the port side which had the stringer crack I am going to do an extra layer.

I then prepped to tab in the back side of the fishbox bulkhead as well as the front fuel tank bulkhead. Then Dug from the board came over for a visit and we chatted for a while. It was nice to meet another fellow board member especially one who works 10min away. Who knew this world was so small.

After Dug left I glassed in the panels, I didn't do high on the fuel tank bulkhead as after fine tuning the fit, I took a bit too much and it wouldn't stand straight and I ended up using a pair of shingles to wedge in and hold it in place.

https://photos.app.goo.gl/r6xjsf89D3gZE8Y67

https://photos.app.goo.gl/e8egh5rSjnpwBQXz9

It rained all day today so I spent time with the family. At least I am prepped to do a bunch of other tasks so hopefully it stays above 60 degrees a couple nights this week.

I then prepped to tab in the back side of the fishbox bulkhead as well as the front fuel tank bulkhead. Then Dug from the board came over for a visit and we chatted for a while. It was nice to meet another fellow board member especially one who works 10min away. Who knew this world was so small.

After Dug left I glassed in the panels, I didn't do high on the fuel tank bulkhead as after fine tuning the fit, I took a bit too much and it wouldn't stand straight and I ended up using a pair of shingles to wedge in and hold it in place.

https://photos.app.goo.gl/r6xjsf89D3gZE8Y67

https://photos.app.goo.gl/e8egh5rSjnpwBQXz9

It rained all day today so I spent time with the family. At least I am prepped to do a bunch of other tasks so hopefully it stays above 60 degrees a couple nights this week.

Re: Bertram 25 conversion to an outboard powered CC

I reinforced the inside stringer on the port side with 2 extra layers of 1708 today, all together there are 5 layers on the side where the stringer crack had occurred. The first layer was 12" wide and the second layer covered the whole bottom as well as stringer side to provide a good base for fairing.

https://photos.app.goo.gl/uck71PJiZ6tsLk4g6

I do not like the way the fast catalyst from LBI is wetting out, it is taking more resin and longer time to work it into the glass. I can't wait for warmer temps. Unfortunately tomorrow is forecast to be the same as today to do the starboard side. I'm going to try putting the resin 5 gallon pail into my basement laundry sink and fill with hot water to hopefully loosen up the resin.

If that works out ok and doesn't make the resin kick too fast I will use the same technique for the inside transom glass this weekend.

anyone else have any tricks to glass when it is 60 degrees out?

https://photos.app.goo.gl/uck71PJiZ6tsLk4g6

I do not like the way the fast catalyst from LBI is wetting out, it is taking more resin and longer time to work it into the glass. I can't wait for warmer temps. Unfortunately tomorrow is forecast to be the same as today to do the starboard side. I'm going to try putting the resin 5 gallon pail into my basement laundry sink and fill with hot water to hopefully loosen up the resin.

If that works out ok and doesn't make the resin kick too fast I will use the same technique for the inside transom glass this weekend.

anyone else have any tricks to glass when it is 60 degrees out?

-

EarleyBird

- Posts: 232

- Joined: Feb 6th, '18, 16:37

Re: Bertram 25 conversion to an outboard powered CC

Gentlemen I believe there is a fella in Stuart, Fl.that has done one or more 25’s. I fished on one in Marathon this past February. The Company’s called L&H Boats, and the gentlemen’s name is Glenn. If you can get a hold of him I’m sure he’ll have a bunch of knowledge to possibly help you. Good Luck with your project.

EarleyBird

EarleyBird

Re: Bertram 25 conversion to an outboard powered CC

thanks for the info.

On another front, One of my friends suddenly got serious and wants to buy my other boat so I will be down to 1 boat soon with no clean way of going fishing. This Bert has to get to the point of being usable this year and preferably by July.

On another front, One of my friends suddenly got serious and wants to buy my other boat so I will be down to 1 boat soon with no clean way of going fishing. This Bert has to get to the point of being usable this year and preferably by July.

Re: Bertram 25 conversion to an outboard powered CC

Glenn from L and H is working on my 31 in Stuart

I redid a 25 with outboards and are using it while my 31 is finished

If you like some picks of the build/ the 25 let me know - I kept it

The way it was( it’s not a center console ) but did a lot of custom items

Spencer

I redid a 25 with outboards and are using it while my 31 is finished

If you like some picks of the build/ the 25 let me know - I kept it

The way it was( it’s not a center console ) but did a lot of custom items

Spencer

Re: Bertram 25 conversion to an outboard powered CC

Sure, I'd love to see pics of your build and would appreciate ideas which would make my project turn out better.

Re: Bertram 25 conversion to an outboard powered CC

I didn't get anything done on the boat due to the cold weather this weekend. I ended up selling my other boat to my buddy so I now have no good way of boat fishing so I better get serious and finish this project.

Re: Bertram 25 conversion to an outboard powered CC

Think twice (maybe three times) before restricting access to your bilge with splash well or live well. I am going through torture rigging this on my belly under my live well with my head hanging in the bilge. Bow thruster rigging is only marginally better crammed in between the deck and sub-deck. This rigging effort is taking alot more time than I ever thought it would.

1963 Bertram 25

1973 Boston Whaler 13 - sold!

1998 Scout 172 SF - beach taxi

1973 Boston Whaler 13 - sold!

1998 Scout 172 SF - beach taxi

Re: Bertram 25 conversion to an outboard powered CC

Hi Cam,

What is this comment in relation to?

I drew out my rough plan (not to scale) - between stringers is @48", fishbox hatch frame is 48" w x28" L, doghouse will be 40-44" wide, livewell will be 36" wide and not sure of length, bomar hatch 15x24"

https://photos.app.goo.gl/v5mF6ZZziNAYAiid6

not shown in plan is draining fishboxes by putting 2 thru-hulls in the center stringer for the fishboxes and run the hoses down through the center stringer into the old motor well are and combine then out through a macerator pump.

Not well shown in the diagram is the front doghouse support, essentially I will put a 3/4" nida core center divider on top of the center stringer and then at the top of it put a wooden beam which will then span across to the main stringers. The center divider will also be on the front side of the fishbox hatch to help support the hatch frame. Also there will probably be more than 2 PVC tubes running all the required cabling and hoses

What is this comment in relation to?

I drew out my rough plan (not to scale) - between stringers is @48", fishbox hatch frame is 48" w x28" L, doghouse will be 40-44" wide, livewell will be 36" wide and not sure of length, bomar hatch 15x24"

https://photos.app.goo.gl/v5mF6ZZziNAYAiid6

not shown in plan is draining fishboxes by putting 2 thru-hulls in the center stringer for the fishboxes and run the hoses down through the center stringer into the old motor well are and combine then out through a macerator pump.

Not well shown in the diagram is the front doghouse support, essentially I will put a 3/4" nida core center divider on top of the center stringer and then at the top of it put a wooden beam which will then span across to the main stringers. The center divider will also be on the front side of the fishbox hatch to help support the hatch frame. Also there will probably be more than 2 PVC tubes running all the required cabling and hoses

Re: Bertram 25 conversion to an outboard powered CC

Just a lesson learned.

Consider using the hollow stringers as rigging tubes. Saves space.

Consider using the hollow stringers as rigging tubes. Saves space.

1963 Bertram 25

1973 Boston Whaler 13 - sold!

1998 Scout 172 SF - beach taxi

1973 Boston Whaler 13 - sold!

1998 Scout 172 SF - beach taxi

Re: Bertram 25 conversion to an outboard powered CC

I've heard repeatedly that the center stringer isn't on later models and thus not needed, that is why I am considering using the space for drain hoses. I'm still a little concerned putting holes in them and was thinking of staggering them so I wouldn't create a weak spot in one place. I also need to figure out what type of 90 degree thru-hull I could use which also might have or be able to put a screen in front of it. I have the ability to get at this area now before the fuel tank goes in and won't be able to get at it again easily in the future so I want to get it right.

On the main stringers, I would agree with you that it is a good place to run wires and hoses but I'm more of a wimp when it comes to cutting into them as I've put so much effort into beefing them up in the mid to front portion of the boat. One idea I had was to put rigging tubes outboard of the stringers by putting a whole through the stringers near the transom and running back in where the fuel fill lines are thus only one cut. I was going to follow your example of filling the outside of the stringers with closed cell foam, I did it on my other boat and it makes a world of difference sound wise. If I went that way, I could use fairly large diameter tubes and it would reduce the volume of foam needed. When I glass my transom I am going to beef up the hull to stringer joint in the motor well area so a cut there doesn't concern me as much.

Other than that, what do you think of the layout? reasonable? trying to plan 5-6 steps ahead in 3 dimensions is not my strong suit but I'd rather think it out wrong a whole bunch of times than execute it wrong once and have to do rework.

On the main stringers, I would agree with you that it is a good place to run wires and hoses but I'm more of a wimp when it comes to cutting into them as I've put so much effort into beefing them up in the mid to front portion of the boat. One idea I had was to put rigging tubes outboard of the stringers by putting a whole through the stringers near the transom and running back in where the fuel fill lines are thus only one cut. I was going to follow your example of filling the outside of the stringers with closed cell foam, I did it on my other boat and it makes a world of difference sound wise. If I went that way, I could use fairly large diameter tubes and it would reduce the volume of foam needed. When I glass my transom I am going to beef up the hull to stringer joint in the motor well area so a cut there doesn't concern me as much.

Other than that, what do you think of the layout? reasonable? trying to plan 5-6 steps ahead in 3 dimensions is not my strong suit but I'd rather think it out wrong a whole bunch of times than execute it wrong once and have to do rework.

Re: Bertram 25 conversion to an outboard powered CC

If you are going with twin tanks then you can surely make use of the space occupied by the center fiberglass stringer. A gigantic center rigging tube running down the center of the boat would be great, and easier to work with than going outboard. In hindsight, now that I'm rigging, I wish I had used the twin tanks instead of a big single for that reason alone. My arrangement is not the cleanest with everything coming up from the side of the console interior. o well!

I wouldn't worry about putting a couple of 2.5" diameter holes in the stringers. They are simple beams and very long.

In general, I think you might have too much weight forward in the boat. The CG of the stock boat is 10 foot forward of the transom - right where your livewell is. If you are keeping the cabin and adding the dog house and fishbox forward, and replacing the I/Os with a single outboard, you might run into problems with trim. Make the dog house as light as possible.

I wouldn't worry about putting a couple of 2.5" diameter holes in the stringers. They are simple beams and very long.

In general, I think you might have too much weight forward in the boat. The CG of the stock boat is 10 foot forward of the transom - right where your livewell is. If you are keeping the cabin and adding the dog house and fishbox forward, and replacing the I/Os with a single outboard, you might run into problems with trim. Make the dog house as light as possible.

1963 Bertram 25

1973 Boston Whaler 13 - sold!

1998 Scout 172 SF - beach taxi

1973 Boston Whaler 13 - sold!

1998 Scout 172 SF - beach taxi

Re: Bertram 25 conversion to an outboard powered CC

Cam,

I will be making the doghouse out of 3/4" nidacore sides and 1/2" top so it will be fairly light, my estimate is that it will be less than 100#, I want the top as light as possible to reduce rolling. I disagree with your estimate that the boat will be bow heavy because Bertram designed the various models to have the helm forward as well as I've removed so much weight from the front of the boat. Also in running the boat for years with my leaning post in about the same location as where the livewell will be going and CC forward I found that the boat loved weight forward. The boat rode better when it was heavily loaded as I would put 2 of the large coolers in the remaining portion of the drop down and fill them with ice and supplies.

I'm actually concerned that I'm going to be too light and will need to add weight. I'm not going to let that stop me from making it light from the start and then trying it out and seeing the results and making adjustments later.

From the stock config I'm probably going to be 300# lighter up front

- Windshield 60#

- replacing cabin bulkheads with nida-core - 30# reduction

- drop down insert removal - 100#

- helm fiberglass molding - 75#

- portion of cabin removed - 40#

- cabin partitions and headliner boards - 30#

I will be making the doghouse out of 3/4" nidacore sides and 1/2" top so it will be fairly light, my estimate is that it will be less than 100#, I want the top as light as possible to reduce rolling. I disagree with your estimate that the boat will be bow heavy because Bertram designed the various models to have the helm forward as well as I've removed so much weight from the front of the boat. Also in running the boat for years with my leaning post in about the same location as where the livewell will be going and CC forward I found that the boat loved weight forward. The boat rode better when it was heavily loaded as I would put 2 of the large coolers in the remaining portion of the drop down and fill them with ice and supplies.

I'm actually concerned that I'm going to be too light and will need to add weight. I'm not going to let that stop me from making it light from the start and then trying it out and seeing the results and making adjustments later.

From the stock config I'm probably going to be 300# lighter up front

- Windshield 60#

- replacing cabin bulkheads with nida-core - 30# reduction

- drop down insert removal - 100#

- helm fiberglass molding - 75#

- portion of cabin removed - 40#

- cabin partitions and headliner boards - 30#

Re: Bertram 25 conversion to an outboard powered CC

Can I catch a break????? weather forecast all week says mid sixty degree weather for today, wake up this morning to 46 and mid day its only low fiftys.

No glassing again today.............................................. another week wasted.

Sad part is monday and tuesday still is supposed to have mid sixty weather but I'm jammed with meetings and can't cut out early.

No glassing again today.............................................. another week wasted.

Sad part is monday and tuesday still is supposed to have mid sixty weather but I'm jammed with meetings and can't cut out early.

Re: Bertram 25 conversion to an outboard powered CC

ok, lets see if the weathermen have got the forecast right for tomorrow..... they say 68 degrees with the threat of some rain late, the boat is covered so I'm not worried about the rain but am worried about the temps. Hopefully I can get the glassing done and put a small electric heater set on 70 degrees and run it overnight.

I managed to clear 2 meetings and can cut out of work at 3 tomorrow and do some glassing.

The area is prepped, 4 layers of 1708 cut out and test fit in the hull based upon this pattern. Before the cutouts to fit the contours the pieces were 78" x 46"

https://photos.app.goo.gl/oM3ZSh92EuYD5YQj9

I'm overlapping

- 14" on either side of the widest part of the bump-out

- 14" on to the stringers

- 6" on the bottom of the hull

I'm praying the weathermen aren't full of BS

I managed to clear 2 meetings and can cut out of work at 3 tomorrow and do some glassing.

The area is prepped, 4 layers of 1708 cut out and test fit in the hull based upon this pattern. Before the cutouts to fit the contours the pieces were 78" x 46"

https://photos.app.goo.gl/oM3ZSh92EuYD5YQj9

I'm overlapping

- 14" on either side of the widest part of the bump-out

- 14" on to the stringers

- 6" on the bottom of the hull

I'm praying the weathermen aren't full of BS

Re: Bertram 25 conversion to an outboard powered CC

Wow! That's going to be a tough lay up to pull off by yourself. Good luck!

1963 Bertram 25

1973 Boston Whaler 13 - sold!

1998 Scout 172 SF - beach taxi

1973 Boston Whaler 13 - sold!

1998 Scout 172 SF - beach taxi

Re: Bertram 25 conversion to an outboard powered CC

Yes Sir it was no fun, I'll be surprised if I can stand up straight tomorrow morning.

I managed to get out of another meeting so I started at 2, sanded for 35min to make sure everything was good, I took off a bit off the top so there would be a smooth transition. I also cut down how much extended on either side on 2 of the pieces because I was a little afraid I didn't have enough resin.

Just when I was about to mix the resin and start, it got interesting - my wife's cat is an escape artist and he jimmy'd my basement door open and went out in the yard. He must have been curious what I was doing as he climbed up the ladder and looked in the boat and started meowing at me. I had to drop my gloves and clean up quick then had to chase him down and put him back in the house. The little focker doesn't go out for a reason because he gets very aggressive, was hissing at me and when I picked him up he bit me. So this little episode cost me a bit of time.

https://photos.app.goo.gl/8TvGUqGMLwtDE2uo9

I mixed up some clean resin, wet everything out then used Cam's technique of mixing up some thickened epoxy on the 1st piece, I made a generous fillet on all the corners and then waited for 15 min to setup a bit before laying in the 1st piece of glass.

1st layer

https://photos.app.goo.gl/VW4VaeFJXbC7wpdc6

2nd layer - went smooth

https://photos.app.goo.gl/ho3oLb5Njukf7spJ8

3rd layer - bubble busting started to get tough, I 'd bust them all then more would show up - No Pic

4th layer - bubble busting still being a pain. I spent almost 30 min bubble busting at the end

https://photos.app.goo.gl/58QsJDLmcTJLST98A

All said and done I was done by 6:30, now for the lessons.......

1. the little tabs that I did from the hull bottom to the stringers were a pain because that is where the drain was

2. The sun was coming through the door in the shrink-wrap, It was messing with the layup, I had to use a squeeze clamp to hold it closed

3. Tyvek suits just don't last. They also always fail in the same exact way, a rip up the thigh into the crotch area. It made it through 2 layers before ripping, another pair of windpants ruined with drips of resin

4. I didn't think about the original deck drains when cutting the glass, ended up with good coverage on top, but not alot of glass over the bottom. I'll have to put more pieces in there later.

5. Even with my cutting and testing not all the pieces fit right when they wet out, I had to make more cuts and left one piece high which will get cut off later.

I managed to get out of another meeting so I started at 2, sanded for 35min to make sure everything was good, I took off a bit off the top so there would be a smooth transition. I also cut down how much extended on either side on 2 of the pieces because I was a little afraid I didn't have enough resin.

Just when I was about to mix the resin and start, it got interesting - my wife's cat is an escape artist and he jimmy'd my basement door open and went out in the yard. He must have been curious what I was doing as he climbed up the ladder and looked in the boat and started meowing at me. I had to drop my gloves and clean up quick then had to chase him down and put him back in the house. The little focker doesn't go out for a reason because he gets very aggressive, was hissing at me and when I picked him up he bit me. So this little episode cost me a bit of time.

https://photos.app.goo.gl/8TvGUqGMLwtDE2uo9

I mixed up some clean resin, wet everything out then used Cam's technique of mixing up some thickened epoxy on the 1st piece, I made a generous fillet on all the corners and then waited for 15 min to setup a bit before laying in the 1st piece of glass.

1st layer

https://photos.app.goo.gl/VW4VaeFJXbC7wpdc6

2nd layer - went smooth

https://photos.app.goo.gl/ho3oLb5Njukf7spJ8

3rd layer - bubble busting started to get tough, I 'd bust them all then more would show up - No Pic

4th layer - bubble busting still being a pain. I spent almost 30 min bubble busting at the end

https://photos.app.goo.gl/58QsJDLmcTJLST98A

All said and done I was done by 6:30, now for the lessons.......

1. the little tabs that I did from the hull bottom to the stringers were a pain because that is where the drain was

2. The sun was coming through the door in the shrink-wrap, It was messing with the layup, I had to use a squeeze clamp to hold it closed

3. Tyvek suits just don't last. They also always fail in the same exact way, a rip up the thigh into the crotch area. It made it through 2 layers before ripping, another pair of windpants ruined with drips of resin

4. I didn't think about the original deck drains when cutting the glass, ended up with good coverage on top, but not alot of glass over the bottom. I'll have to put more pieces in there later.

5. Even with my cutting and testing not all the pieces fit right when they wet out, I had to make more cuts and left one piece high which will get cut off later.

Re: Bertram 25 conversion to an outboard powered CC

That looks great! Congratulations!

When I was working the boat in my driveway in the summertime, I used to get up just before dawn to glass before the sun hit the boat and things got too hot to work. My neighbors would be leaving for work, and I'd be up on the boat slinging epoxy. I got some odd looks, but they know I have "issues".

When I was working the boat in my driveway in the summertime, I used to get up just before dawn to glass before the sun hit the boat and things got too hot to work. My neighbors would be leaving for work, and I'd be up on the boat slinging epoxy. I got some odd looks, but they know I have "issues".

1963 Bertram 25

1973 Boston Whaler 13 - sold!

1998 Scout 172 SF - beach taxi

1973 Boston Whaler 13 - sold!

1998 Scout 172 SF - beach taxi

Re: Bertram 25 conversion to an outboard powered CC

when good weather is here, got to take advantage of it... plus I had no ambition to do any sanding so I stayed away from the transom.

so I put the final layer of glass in the starboard fishbox - the slow hardener from LBI is a PAIN to work with, slow to wet out and real tough to bust air bubbles. I can't wait for warmer weather so I don't have to mess with it.

https://photos.app.goo.gl/UgEhXbGEXAZmyDsi7

I've got a 500 watt halogen on it and will leave it on until I go to work tomorrow morning.

so I put the final layer of glass in the starboard fishbox - the slow hardener from LBI is a PAIN to work with, slow to wet out and real tough to bust air bubbles. I can't wait for warmer weather so I don't have to mess with it.

https://photos.app.goo.gl/UgEhXbGEXAZmyDsi7

I've got a 500 watt halogen on it and will leave it on until I go to work tomorrow morning.

Re: Bertram 25 conversion to an outboard powered CC

Cam,

I didn't read your post thoroughly, I have to admit I probably have similar issues. Being happy to get out of work to get myself into a pretzel position and spreading epoxy befuddles my co-workers.

I didn't read your post thoroughly, I have to admit I probably have similar issues. Being happy to get out of work to get myself into a pretzel position and spreading epoxy befuddles my co-workers.

Re: Bertram 25 conversion to an outboard powered CC

I bet you hear the same line as I have for 10 years: "Can't you just buy a boat?"

1963 Bertram 25

1973 Boston Whaler 13 - sold!

1998 Scout 172 SF - beach taxi

1973 Boston Whaler 13 - sold!

1998 Scout 172 SF - beach taxi

Re: Bertram 25 conversion to an outboard powered CC

my spreadsheet tracking costs is growing, growing to a point which could make your wife's point.

on the flip side, I've ridden on a bunch of boats and not many can match the Bertram's ride, the ones that come close or exceed it and have brand new power are WELL beyond what I am going to spend for my project.

Most of the boats today have a 8' or 8'6" beam, I'll gladly give up a few kts speed in a headsea run to get the width and sea keeping ride of the Bert.

on the flip side, I've ridden on a bunch of boats and not many can match the Bertram's ride, the ones that come close or exceed it and have brand new power are WELL beyond what I am going to spend for my project.

Most of the boats today have a 8' or 8'6" beam, I'll gladly give up a few kts speed in a headsea run to get the width and sea keeping ride of the Bert.

Re: Bertram 25 conversion to an outboard powered CC

testing another way to post images.... It is visible to me after I signed out of Google Photos, do others see pic or red X?

https://lh3.googleusercontent.com/6vo79 ... ezUQ=w2400

I'm still messing with this............................. It seems that the link works to generate a url that can be posted via the url tag, but when you post the image in the IMG tag it doesn't take it. This could be the UBB software looking for a .jpg at the end of the url string. I am going to continue to try combinations to figure out how to make it work.

trying combinations from this website and it doesn't seem to want to work.

https://www.labnol.org/internet/embed-g ... ite/29194/

https://lh3.googleusercontent.com/6vo79 ... ezUQ=w2400

I'm still messing with this............................. It seems that the link works to generate a url that can be posted via the url tag, but when you post the image in the IMG tag it doesn't take it. This could be the UBB software looking for a .jpg at the end of the url string. I am going to continue to try combinations to figure out how to make it work.

trying combinations from this website and it doesn't seem to want to work.

https://www.labnol.org/internet/embed-g ... ite/29194/

Last edited by ktm_2000 on May 13th, '19, 22:42, edited 23 times in total.

Re: Bertram 25 conversion to an outboard powered CC

ktm_2000 wrote:testing another way to post images.... It is visible to me after I signed out of Google Photos, do others see pic or red X?

Hey KTM... The image isn't visible... just a blue question mark for me... Even pasting the entire link into a new browser doesn't show the image... just something that looks like a gray "do not enter" sign without the words.

HotSpot - ‘61 25 Sport Convertible - Hull# 25-109

Re: Bertram 25 conversion to an outboard powered CC

ok, I was reading posts on other sites on how to post photos directly without posting links, I guess it doesn't work as expected.

Re: Bertram 25 conversion to an outboard powered CC

Saturday I glassed the port side from the base of the hull up onto the stringer in the old motor well area. I did 4 layers of 1708, I also overlapped onto the transom 8 or so inches so now there should be 8 layers of 1708 going from the transom onto the main stringers. With snow in the forecast for tonight, I guess I am waiting to do the starboard side, late this week.

since we are getting more cold weather, I want to work on items which don't involve glassing, I am interested in adding a knee over the center stringer so I have 3 reinforced points where the stringers meet the transom. I was thinking of having 2/3 layers of 3/4" ply glued together which sit on top of the center stringer and match the transom angle. The pieces could be glassed to both the center stringer + the transom and act as a stiffener for the transom as well as a center support for the nida-core deck.

since we are getting more cold weather, I want to work on items which don't involve glassing, I am interested in adding a knee over the center stringer so I have 3 reinforced points where the stringers meet the transom. I was thinking of having 2/3 layers of 3/4" ply glued together which sit on top of the center stringer and match the transom angle. The pieces could be glassed to both the center stringer + the transom and act as a stiffener for the transom as well as a center support for the nida-core deck.

- mike ohlstein

- Site Admin

- Posts: 2396

- Joined: Jun 29th, '06, 11:39

- Location: So many things seem like no-brainers until you run into someone with no brain.

- Contact:

Re: Bertram 25 conversion to an outboard powered CC

You can only share google stored photos with people who have a google account, and only then if you create a special 'share link' and post the link.

Open a free IMGUR account. Upload a photo. Create a link. Enter the link here as an image.

https://imgur.com/

Open a free IMGUR account. Upload a photo. Create a link. Enter the link here as an image.

https://imgur.com/

- mike ohlstein

- Site Admin

- Posts: 2396

- Joined: Jun 29th, '06, 11:39

- Location: So many things seem like no-brainers until you run into someone with no brain.

- Contact:

Re: Bertram 25 conversion to an outboard powered CC

Use their 'Direct Link' option

Re: Bertram 25 conversion to an outboard powered CC

Hi Mike,

I have a rather large google photos library and want to stick with that for sharing, I know how to link using the url tag but can't seem to be able to find a way to link via the img tag. I had looked at an article which stated that you could share a pic directly and bypass the google page. In testing this I kept seeing the image and thought it was working but it must have been since the image was stored was in my browser cache.

I will continue to add pics to my posts via the url tag and if I can find a way to present it up via img tag, I will share with the board.

I have a rather large google photos library and want to stick with that for sharing, I know how to link using the url tag but can't seem to be able to find a way to link via the img tag. I had looked at an article which stated that you could share a pic directly and bypass the google page. In testing this I kept seeing the image and thought it was working but it must have been since the image was stored was in my browser cache.

I will continue to add pics to my posts via the url tag and if I can find a way to present it up via img tag, I will share with the board.

Re: Bertram 25 conversion to an outboard powered CC

got some work done this week, glassed from the hull bottom up onto the stringers and transom in the motor well area. The color difference is because I used the fast hardener.

https://photos.app.goo.gl/3giQc3vEXYRczy6x5

I also got the transom prepped to glass the I/O holes. It seems like the vertical line would be from the 2 piece mold being joined together. One thing that somewhat has me spooked is that the glass doesn't have the Bertram green. I'm wondering if my boat once had volvo motors and a previous owner had the transom done over from the outside to make it suitable for mercruiser motors?

https://photos.app.goo.gl/EP7nCQXK6PUivpDy7

Started laying up panels to build the doghouse. I'm going to fabricate (3) 3/4" nidacore panels, then do a design and mock up out of 3/8" OSB. Once I am happy with how it looks, carve up the nida core and tape the seams to join all the pieces. Once in the right shape I will cover it all in a 2nd layer of 1708.

https://photos.app.goo.gl/yvoYUdokexdu5gTb8

I also started planning on a knee to brace the center stringer to the transom. I first did the back piece out of some scrap material, I left it short so there would be space for the hatch which will be above and in front of it. I thought it wouldn't have enough bonding area to make a big enough difference, so I started thinking about a longer piece and the pic is my current idea, if I go this way, I would make a 2-3 new pieces the same as the drawing out of 3/4" marine ply. I'm still not happy about the whole setup as there isn't much of a knee so I thing this is still in concept phase.

https://photos.app.goo.gl/1yHdhHc3fdsnRxoS6

https://photos.app.goo.gl/3giQc3vEXYRczy6x5

I also got the transom prepped to glass the I/O holes. It seems like the vertical line would be from the 2 piece mold being joined together. One thing that somewhat has me spooked is that the glass doesn't have the Bertram green. I'm wondering if my boat once had volvo motors and a previous owner had the transom done over from the outside to make it suitable for mercruiser motors?

https://photos.app.goo.gl/EP7nCQXK6PUivpDy7

Started laying up panels to build the doghouse. I'm going to fabricate (3) 3/4" nidacore panels, then do a design and mock up out of 3/8" OSB. Once I am happy with how it looks, carve up the nida core and tape the seams to join all the pieces. Once in the right shape I will cover it all in a 2nd layer of 1708.

https://photos.app.goo.gl/yvoYUdokexdu5gTb8

I also started planning on a knee to brace the center stringer to the transom. I first did the back piece out of some scrap material, I left it short so there would be space for the hatch which will be above and in front of it. I thought it wouldn't have enough bonding area to make a big enough difference, so I started thinking about a longer piece and the pic is my current idea, if I go this way, I would make a 2-3 new pieces the same as the drawing out of 3/4" marine ply. I'm still not happy about the whole setup as there isn't much of a knee so I thing this is still in concept phase.

https://photos.app.goo.gl/1yHdhHc3fdsnRxoS6

- Waytooslow

- Posts: 88

- Joined: Aug 20th, '16, 22:52

Re: Bertram 25 conversion to an outboard powered CC

Ktm send me an email and I will send you a picture of my knees. Last time I posed a picture it had Cam in a Tutu so I don't dare try that again. Todd

toddwest at bellsouth.net

toddwest at bellsouth.net

1963 B-25 Project (in process)

Atl. GA

Atl. GA

Re: Bertram 25 conversion to an outboard powered CC

WaytooSlow, I sent you an email.

This weekend was busy, my goal was to laminate 3 panels of nidacore. Friday it stopped raining at 3pm and seemed dry enough by 6 that I felt safe so I laminated one side of a piece of nidacore. Saturday morning I setup another laminating table and did the second side of the 1st panel and the front side of a second. I then beveled the I/O holes on the transom and glassed 4 layers of 1708 into the holes overlapping everything. I don't know what problem I ran into but bubbles kept appearing in the laminate and I had to sit and bubble bust for an hour and I thought it was tacky enough to not make more. We had plans for company coming over so I could not babysit it and left to get ready to go out.

This morning I went out to check out the boat and unfortunately another bubble came up and I will have to grind it out and fill the hole. I ground the glass that I layed in the I/O holes flush with the transom and (I should have listened to Cam) as I am probably 2 layers too thin. Since I was already dusty I cleaned up the excess glass from the nida core panels and it started raining so I moved everything indoors.

We went for a ride and it stopped raining, so we did a hike up Mt Wachusett and got home before dinner. I skipped eating and glassed the second side of the second panel as well as the first side of the 3rd panel. I let it cure out to 10pm and covered them up with plastic as it is going to rain overnight. Tomorrow is supposed to be hot so I'm going to get up and laminate the second side of the 3rd panel before work. I may have to work from home as it is supposed to rain tomorrow afternoon and I won't have time to laminate the panel and have it cure enough to put plastic on it before I need to be in work.

This rain is getting to be a bit much, yesterday was probably the first day in 3 weeks that it didn't rain sometime during the day.

This weekend was busy, my goal was to laminate 3 panels of nidacore. Friday it stopped raining at 3pm and seemed dry enough by 6 that I felt safe so I laminated one side of a piece of nidacore. Saturday morning I setup another laminating table and did the second side of the 1st panel and the front side of a second. I then beveled the I/O holes on the transom and glassed 4 layers of 1708 into the holes overlapping everything. I don't know what problem I ran into but bubbles kept appearing in the laminate and I had to sit and bubble bust for an hour and I thought it was tacky enough to not make more. We had plans for company coming over so I could not babysit it and left to get ready to go out.

This morning I went out to check out the boat and unfortunately another bubble came up and I will have to grind it out and fill the hole. I ground the glass that I layed in the I/O holes flush with the transom and (I should have listened to Cam) as I am probably 2 layers too thin. Since I was already dusty I cleaned up the excess glass from the nida core panels and it started raining so I moved everything indoors.

We went for a ride and it stopped raining, so we did a hike up Mt Wachusett and got home before dinner. I skipped eating and glassed the second side of the second panel as well as the first side of the 3rd panel. I let it cure out to 10pm and covered them up with plastic as it is going to rain overnight. Tomorrow is supposed to be hot so I'm going to get up and laminate the second side of the 3rd panel before work. I may have to work from home as it is supposed to rain tomorrow afternoon and I won't have time to laminate the panel and have it cure enough to put plastic on it before I need to be in work.

This rain is getting to be a bit much, yesterday was probably the first day in 3 weeks that it didn't rain sometime during the day.

Re: Bertram 25 conversion to an outboard powered CC

I didn't have grinding / laying fiberglass in me today so I decided to have some fun and to some design of the doghouse. I picked up 3 OSB panels and started messing drawing and cutting.

I drew this image a while back based upon the hull drawing I found here. The drawing is 2d and doesn't account for having a v-shaped area for the windows.

https://photos.app.goo.gl/SaPn7w3syCwhumg28

I'm not happy with it, seems to much of the slanted portion up top. I somewhat modeled it off my old center console which was 48" high, I made it 6'8", I measured up 48" from the bottom and came in 2" to put somewhat of a slant on the front side, from there I came in 2" more to account for the outside of the windows being further back than the center and then drew out angles of 45,60,70, 75 degrees. 45 was an obvious no go so I then cut at 75 took a pic (too straight up), 70 degrees was somewhat better but seemed too high in the window area, I then cut off 2" off the top to make it 6'6" and then made a window outline.

Here's the end of todays attempt

https://photos.app.goo.gl/mTsM2WvVWfTrKMZe9

I'm thinking that I want the window area smaller and higher up and more depth front to back. It will probably take me a few attempts to get it right and at $10 a sheet of OSB, I would rather mess it up a bunch with OSB rather than make an ugly doghouse.

I drew this image a while back based upon the hull drawing I found here. The drawing is 2d and doesn't account for having a v-shaped area for the windows.

https://photos.app.goo.gl/SaPn7w3syCwhumg28

I'm not happy with it, seems to much of the slanted portion up top. I somewhat modeled it off my old center console which was 48" high, I made it 6'8", I measured up 48" from the bottom and came in 2" to put somewhat of a slant on the front side, from there I came in 2" more to account for the outside of the windows being further back than the center and then drew out angles of 45,60,70, 75 degrees. 45 was an obvious no go so I then cut at 75 took a pic (too straight up), 70 degrees was somewhat better but seemed too high in the window area, I then cut off 2" off the top to make it 6'6" and then made a window outline.

Here's the end of todays attempt

https://photos.app.goo.gl/mTsM2WvVWfTrKMZe9

I'm thinking that I want the window area smaller and higher up and more depth front to back. It will probably take me a few attempts to get it right and at $10 a sheet of OSB, I would rather mess it up a bunch with OSB rather than make an ugly doghouse.

Re: Bertram 25 conversion to an outboard powered CC

oh, here's a boat that I like the looks of padebco 29 CC

https://photos.app.goo.gl/syguySarDJiGdUD2A

https://photos.app.goo.gl/AR3XycDTQKnCJFPG6

is there a decent technique for taking an image and rendering a scale model of it?

https://photos.app.goo.gl/syguySarDJiGdUD2A

https://photos.app.goo.gl/AR3XycDTQKnCJFPG6

is there a decent technique for taking an image and rendering a scale model of it?

Re: Bertram 25 conversion to an outboard powered CC

I had good luck making full size 3D models with foam insulation board from HD or Lowes and roll of duct tape. quick and easy, no saw dust

I like your Padebco model. If you know what you want in the profile view, maybe you can make a giant "white board" to set on deck. Some thing that allows you to draw and erase, or use tape to out line the full scale profile of the dog house. Once you create the profile, you can make a full 3D model with foam board or OSB. No scaling required, and you can pull dimensions right off the model for construction of the real deal.

just an early morning thought...

I like your Padebco model. If you know what you want in the profile view, maybe you can make a giant "white board" to set on deck. Some thing that allows you to draw and erase, or use tape to out line the full scale profile of the dog house. Once you create the profile, you can make a full 3D model with foam board or OSB. No scaling required, and you can pull dimensions right off the model for construction of the real deal.

just an early morning thought...

1963 Bertram 25

1973 Boston Whaler 13 - sold!

1998 Scout 172 SF - beach taxi

1973 Boston Whaler 13 - sold!

1998 Scout 172 SF - beach taxi

Re: Bertram 25 conversion to an outboard powered CC

Cam.

I like the idea of using tape, I generated a bunch of firewood yesterday and don't want to keep wasting if I don't have to. Once I get the profile right I do want to make it out of OSB to make sure It works as expected as well as use it as a test bed for how to set up the helm

I like the idea of using tape, I generated a bunch of firewood yesterday and don't want to keep wasting if I don't have to. Once I get the profile right I do want to make it out of OSB to make sure It works as expected as well as use it as a test bed for how to set up the helm

-

Ttownthomas

- Posts: 111

- Joined: Aug 12th, '18, 09:21

Re: Bertram 25 conversion to an outboard powered CC

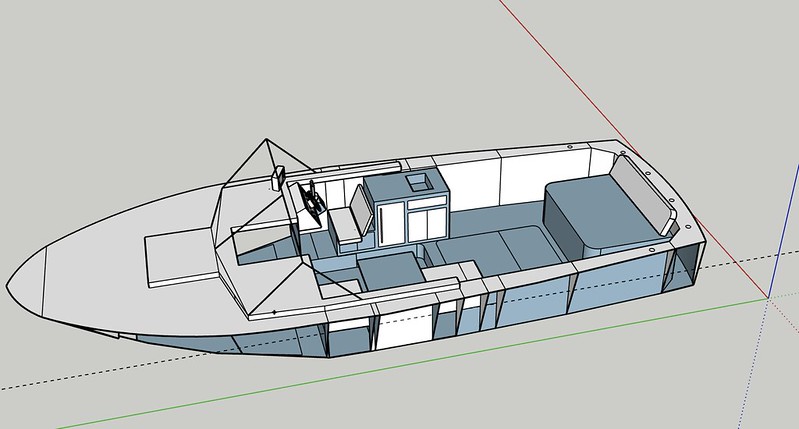

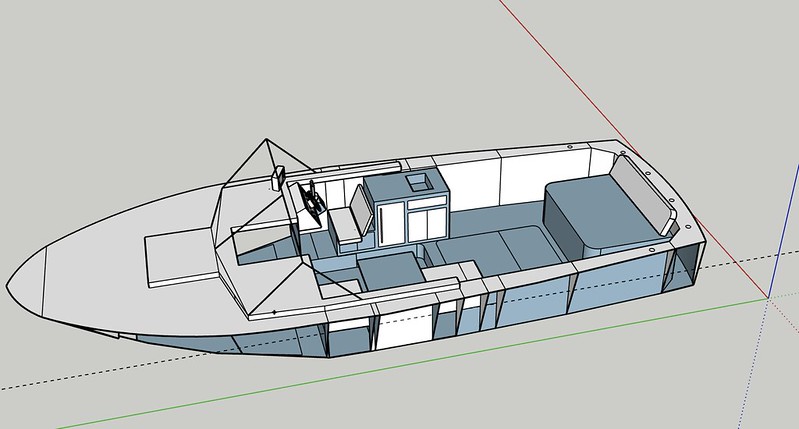

I know you are way beyond this step but I have found sketch-up free to be a valuable 3D planning tool. I could send you my file to save you some leg-work if you want it.

Screen Shot 2019-05-24 at 12.22.50 PM by ttownthomas, on Flickr

Screen Shot 2019-05-24 at 12.22.50 PM by ttownthomas, on Flickr

Screen Shot 2019-05-24 at 12.22.50 PM by ttownthomas, on Flickr

Screen Shot 2019-05-24 at 12.22.50 PM by ttownthomas, on FlickrRe: Bertram 25 conversion to an outboard powered CC

Wow!!!!!! you've got skills in sketchup. that tool befuddles me, starting and dragging to hit specific sizes is rough, no easy way to type them in.

On a side note, notching the transom might be back on the plan. I called Bob's Machine shop and tried to order a Jackplate and they told me 6-8 weeks. I've called a few other places which sell their products and everyone of them don't stock the items but takes your order and then places it with Bob's. Why don't marine businesses stock up in advance to be able to fill orders in the spring?? one of the distributors says Bob's moved locations and that is causing issues???

If it is the 8 weeks, that puts me end of July. I wanted to be at a state of structurally sound and usable but ugly cosmetically by July.

My issue here is that based upon Cam's post (see below) that the height required for the Bracket puts the bolts in line with where the deck would want to go. Ideally I would want to get the bracket, temp mount it and figure out where everything needed to land, remove the bracket and build out my deck, once everything is finished mount it for good. I really don't want to wait that long to get this right nor do I want to do rework once I get the jackplate. dilemma I'm wondering if I bought their product, they would give me an engineering drawing that I could print out and make a full size template so I could do what I just described without actually having the jackplate????

On a side note, notching the transom might be back on the plan. I called Bob's Machine shop and tried to order a Jackplate and they told me 6-8 weeks. I've called a few other places which sell their products and everyone of them don't stock the items but takes your order and then places it with Bob's. Why don't marine businesses stock up in advance to be able to fill orders in the spring?? one of the distributors says Bob's moved locations and that is causing issues???

If it is the 8 weeks, that puts me end of July. I wanted to be at a state of structurally sound and usable but ugly cosmetically by July.

My issue here is that based upon Cam's post (see below) that the height required for the Bracket puts the bolts in line with where the deck would want to go. Ideally I would want to get the bracket, temp mount it and figure out where everything needed to land, remove the bracket and build out my deck, once everything is finished mount it for good. I really don't want to wait that long to get this right nor do I want to do rework once I get the jackplate. dilemma I'm wondering if I bought their product, they would give me an engineering drawing that I could print out and make a full size template so I could do what I just described without actually having the jackplate????

CamB25 wrote:Welcome to the darker side...outboard and a jackplate! You are downright crazy, man!

Powder coating looks good, but unlike chrome on your engine, it has no performance advantage!

I wouldn't add more glass to the outside of the transom as it will be a PITA to fair with no benefit. Taper grind the I/O holes to a shallow angle so you get significant overlap between new glass and old glass when you fill the shallow holes. Might require more than 4 or 5 layers, but I don't remember how how thick the outer glass is.

If you want to add more strength to the assembly or to distribute the loads over a wider area, work on the inside. I glassed in a 1/4" aluminum bar in the plane formed by the jackplate's top mounting holes. Serves as a gigantic washer.

A couple of notes:

- I made a plywood template of the jackplate mounting surface/holes to have something light weight to work with.

- Use a drill base to ensure your holes are straight. Use a wood boring bit.

- Watch out for the location of the lower mounting holes and your deck. My lower holes interfere with the deck and required some deck work to get access. (my deck was raised 3/4" over stock and is 1" or so thick.)

- Mounting height of the jack plate was an educated guess.

- Buy the Bob's thru-transom fittings and use 4 hoses. Otherwise you have to drill big holes in the transom to get the hose and fittings to pass ( I learned about the thru-fittings too late).

Here are a couple of pictures. The filled holes are from my first idea to use a simple 30", single engine bracket.

https://www.amazon.com/photos/shared/CY ... M0gLR7rT31

Found a shot of the inside. https://www.amazon.com/photos/shared/co ... G_aep2NXnR

The holes with the red plugs are for the jackplate.

-

Ttownthomas

- Posts: 111

- Joined: Aug 12th, '18, 09:21

Re: Bertram 25 conversion to an outboard powered CC

You have been given bad training. It is very easy to type in dimensions.ktm_2000 wrote: that tool befuddles me, starting and dragging to hit specific sizes is rough, no easy way to type them in.

Re: Bertram 25 conversion to an outboard powered CC

I'm on a phone...

I still have my template. Will send to you if needed.

Based on my gymnastics exercise, you don't need any lift to clear water at 10 inch setbaxk. Could use a fixed bracket with slight notch in transom.

I still have my template. Will send to you if needed.

Based on my gymnastics exercise, you don't need any lift to clear water at 10 inch setbaxk. Could use a fixed bracket with slight notch in transom.

1963 Bertram 25

1973 Boston Whaler 13 - sold!

1998 Scout 172 SF - beach taxi

1973 Boston Whaler 13 - sold!

1998 Scout 172 SF - beach taxi

Re: Bertram 25 conversion to an outboard powered CC

Cam,

I sent an email to the fabricator who is building my fuel tank to get a quote on a regular bracket that has a top which extends to the sides of the bump-out, I also sent an email to bob's and one of their managers wrote back that they had a 1000+ unit back-order so their business must be good.

I'm going to see what the regular bracket comes back at along with the lead time for it, as I am also waiting on my fuel tank. If that is way more expensive than the bob's plus the lead time similar I will go with the Bob's. It seems the bolt pattern is the same as a standard outboard bolt pattern which I found on the web. I should be able to make a template from these instructions.

Top pair of holes are spaced 12-7/8" o.c.

The bottom pair of holes are spaced 9-7/8-inch o.c.

The spacing between the top and bottom pair of holes is 8" o.c.

The holes in the transom should be 1-7/8" below the top of the transom.

Ttownthomas, you are probably right on the training aspect. the few youtube videos I watched state that it is fairly easy but for whatever reason that tool and I don't mix.

I'm going to take the weekend off and build up brownie points with the wife since I've been burning up a lot of goodwill lately working every chance I get on the boat.

I sent an email to the fabricator who is building my fuel tank to get a quote on a regular bracket that has a top which extends to the sides of the bump-out, I also sent an email to bob's and one of their managers wrote back that they had a 1000+ unit back-order so their business must be good.

I'm going to see what the regular bracket comes back at along with the lead time for it, as I am also waiting on my fuel tank. If that is way more expensive than the bob's plus the lead time similar I will go with the Bob's. It seems the bolt pattern is the same as a standard outboard bolt pattern which I found on the web. I should be able to make a template from these instructions.

Top pair of holes are spaced 12-7/8" o.c.

The bottom pair of holes are spaced 9-7/8-inch o.c.

The spacing between the top and bottom pair of holes is 8" o.c.

The holes in the transom should be 1-7/8" below the top of the transom.

Ttownthomas, you are probably right on the training aspect. the few youtube videos I watched state that it is fairly easy but for whatever reason that tool and I don't mix.

I'm going to take the weekend off and build up brownie points with the wife since I've been burning up a lot of goodwill lately working every chance I get on the boat.

Re: Bertram 25 conversion to an outboard powered CC

Decisions,decisions, decisions............

finally got back with the fabricator and a bracket with a small swim platform the width of the transom bump-out would be 2k + an unknown cost for painting bolts etc, sub 1 month for delivery. I've tracked down a person on ebay who actually has Bob's brackets in stock but they are the action series which has the pump inside the bracket and can get wet - would be at my door in 4-5 days. Ideally I would want one of the standard series and put the pump inside the boat.

Which would you do?

finally got back with the fabricator and a bracket with a small swim platform the width of the transom bump-out would be 2k + an unknown cost for painting bolts etc, sub 1 month for delivery. I've tracked down a person on ebay who actually has Bob's brackets in stock but they are the action series which has the pump inside the bracket and can get wet - would be at my door in 4-5 days. Ideally I would want one of the standard series and put the pump inside the boat.

Which would you do?

Re: Bertram 25 conversion to an outboard powered CC

I pulled the trigger on the Bob's Jackplate through a ebay seller, will be at my house in about a week.

my thoughts is if I notch the transom it would be very difficult to get back to where I am right now. If I don't like the Jackplate, $2k and a bunch of effort will get me a full bracket or a bunch of effort I can notch the transom and hang the motor, this method lets me move forward this year.

my thoughts is if I notch the transom it would be very difficult to get back to where I am right now. If I don't like the Jackplate, $2k and a bunch of effort will get me a full bracket or a bunch of effort I can notch the transom and hang the motor, this method lets me move forward this year.

Re: Bertram 25 conversion to an outboard powered CC

I got a few hours of work in on Friday, added 2 more layers of 1708 to I/O holes thinking it would be the last (more on this to come) then I started working on making a storage area inside the fishboxes. It took a while to get the angles and curves of the bottom of the boat worked out then I cut out another piece as a front lip. To attach the 2 pieces together I set the saw up to cut through 3/4 of the panel then I cleaned up the edge with a chisel and utility knife leaving just the glass on the second side. I put packing tape along the edges of a 2x4 to act as a clamping device and clamped it right up to the edge of the larger piece then I mixed up some resin with high density filler and cabosil and filled the joint with the mix then clamped the lip to the 2x4. There was excess filler so I used it to fill in the honeycomb of the nidacore on the top lip.

In order to pickup the load of the center console I added a center partition sitting on the top of the center stringer. I put a set of clamps on the bulkhead to hold it vertical, then setup another 2x4 with more clamps to hold it still in the center of the boat. 2 strips of 1708 went down on either side to tab it in place.

https://photos.app.goo.gl/K6DnDBs8jvCQUaED7

I spent Saturday with the family and managed to get working on the boat this afternoon. I started by grinding the I/O holes flush with the transom and it still was not flat so I added layers 7&8 to the holes. If this isn't enough I'm going to make up a fairing compound of west high density filler + cabosil to make up the difference.

The part I made for storage friday came out fine, I hit the edge of the filler used to fill in the honeycomb with a grinder and made it flush, and then ground the bottom edge to make a small radius. from there I added more reinforcement to the inside joint by adding a layer of 1708 then capped the filler with a piece of 1708 leaving it to overhang. Tomorrow I will clean it up with a grinder.

I took off the clamps off the center divider and added 2 layers of 1708 on the verticals and capped the front edge which will be exposed with filler and a layer of 1708 as I did with the top lip of the storage.

In order to pickup the load of the center console I added a center partition sitting on the top of the center stringer. I put a set of clamps on the bulkhead to hold it vertical, then setup another 2x4 with more clamps to hold it still in the center of the boat. 2 strips of 1708 went down on either side to tab it in place.

https://photos.app.goo.gl/K6DnDBs8jvCQUaED7

I spent Saturday with the family and managed to get working on the boat this afternoon. I started by grinding the I/O holes flush with the transom and it still was not flat so I added layers 7&8 to the holes. If this isn't enough I'm going to make up a fairing compound of west high density filler + cabosil to make up the difference.

The part I made for storage friday came out fine, I hit the edge of the filler used to fill in the honeycomb with a grinder and made it flush, and then ground the bottom edge to make a small radius. from there I added more reinforcement to the inside joint by adding a layer of 1708 then capped the filler with a piece of 1708 leaving it to overhang. Tomorrow I will clean it up with a grinder.

I took off the clamps off the center divider and added 2 layers of 1708 on the verticals and capped the front edge which will be exposed with filler and a layer of 1708 as I did with the top lip of the storage.

Re: Bertram 25 conversion to an outboard powered CC

Now for dilemma.............

I wanted to put in a battery box in the old motor well. In measuring from the top of the stringers to the bottom of where the deck will end up there is only 10" the battery will need all of that so that is not an option. I also measured the space left over between the fishboxes and fuel tanks and there isn't much more vertical room there if I add 3/4" as a base https://photos.app.goo.gl/ozWdrkeXCqT6hzcbA

I was contemplating putting my house batteries in a box at the foot of the doghouse but wanted to keep the starting batteries closer to the motor.

so here's my dilemma,

1. make a battery box mounting point in the motor well but lower down in the hull

2. make a battery box mounting point lower in the hull in the unused space, this has a drawback as I will need another hatch in the deck

3. place all my batteries in a battery box which I make in the foot of the doghouse and spend extra to get really heavy duty battery cables to run power back to the motor.

so am I better off having my starting battery sitting low in the old motorwell or having longer @12' heavy duty cables which are sized appropriately for the length of run?

I wanted to put in a battery box in the old motor well. In measuring from the top of the stringers to the bottom of where the deck will end up there is only 10" the battery will need all of that so that is not an option. I also measured the space left over between the fishboxes and fuel tanks and there isn't much more vertical room there if I add 3/4" as a base https://photos.app.goo.gl/ozWdrkeXCqT6hzcbA

I was contemplating putting my house batteries in a box at the foot of the doghouse but wanted to keep the starting batteries closer to the motor.

so here's my dilemma,

1. make a battery box mounting point in the motor well but lower down in the hull

2. make a battery box mounting point lower in the hull in the unused space, this has a drawback as I will need another hatch in the deck

3. place all my batteries in a battery box which I make in the foot of the doghouse and spend extra to get really heavy duty battery cables to run power back to the motor.

so am I better off having my starting battery sitting low in the old motorwell or having longer @12' heavy duty cables which are sized appropriately for the length of run?

Re: Bertram 25 conversion to an outboard powered CC

I would try to keep the batteries together. You can cut down that center stringer and get more headroom for the batteries

1963 Bertram 25

1973 Boston Whaler 13 - sold!

1998 Scout 172 SF - beach taxi

1973 Boston Whaler 13 - sold!

1998 Scout 172 SF - beach taxi

Who is online

Users browsing this forum: Bing [Bot] and 61 guests