Last summer I installed a simple NMEA 2000 network connecting the VHF, GPS/Sounder and fuel flow sensors.

I've been delighted with the results and am emboldened to go further.

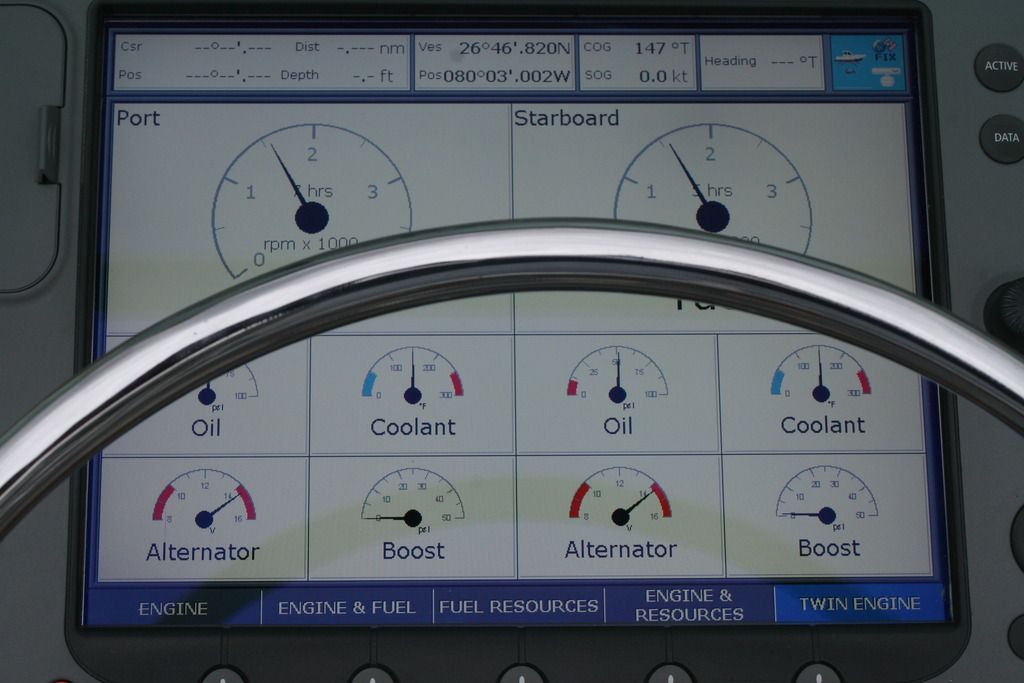

The next step, I think, is a NMEA 2000 analog interface to include engine gauge data on the network. I am partially taking this on as the gauges are tired and the helm needs a rot-ectomy. I plan to eliminate the gauges. I see this as an opportunity to reduce the wiring running to the helm and clean it up significantly.

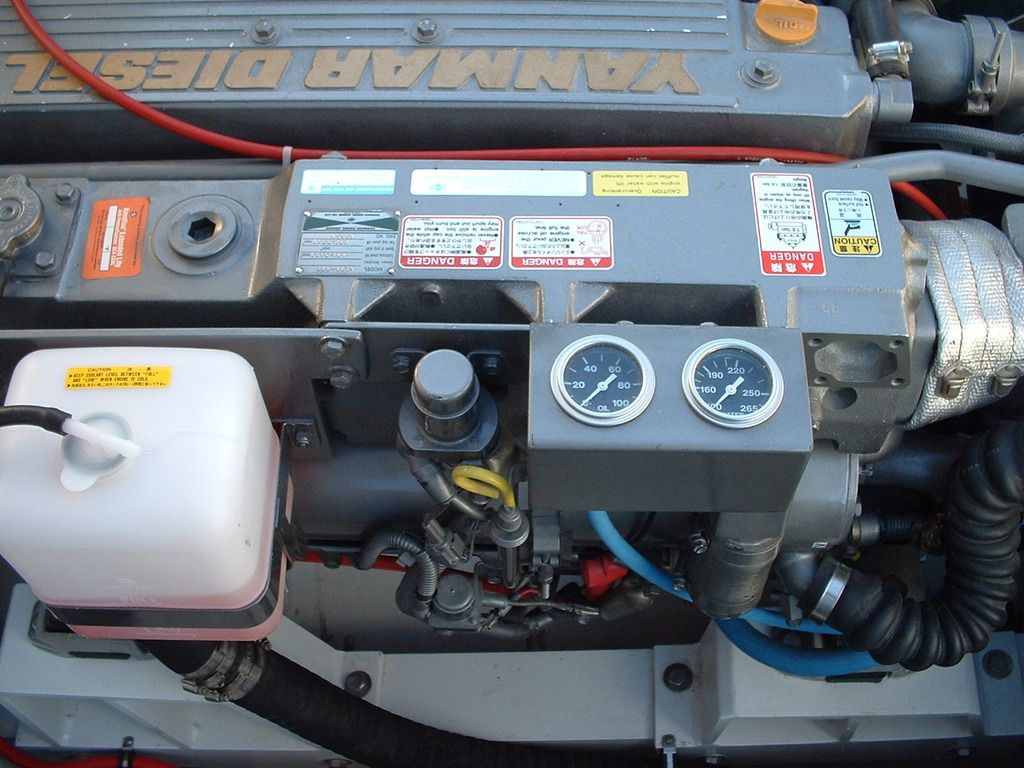

The engines (1992 Crusader 454s) have character and after 4 seasons together, healthy oil analyses and a little TLC, they are good mills and good for me. I am under the impression that we are in sync and I have a sense of the rumbles, smells and sounds independent of where a needle on a gauge is pointing.

I ask for your perspective. I have and always will respect your advice. On this one though I want to try this and hope the tuition I pay isn’t too awful. This thread can be the record of my folly (or victory) and has all the room of cyberspace’s back 40 for warning, caution and I told you so.

I think I can….