Fiberglass Windshield Layup Schedule

Moderators: CaptPatrick, mike ohlstein, Bruce

- Vince Luciani

- Senior Member

- Posts: 172

- Joined: Jul 1st, '06, 09:50

- Location: Rehoboth Beach, Delaware

Fiberglass Windshield Layup Schedule

Hello all,

I am looking to fabricate a fiberglass windshield for my Sportfish model and i am looking for some recommendations on layup schedule. I know some here have fabricated their windshield themselves (as opposed to installing the Holmsey product). I have pulled molds off the existing windshield and am ready to start with my layup. I saw an old post by Spencer where he talked about 2 layers of 1/2 inch Divyncell and 1708 biaxial. How many layers of 1708 per side? Did you reinforce with plywood or any thicker sections or was the windsheild a uniform 1" thickness (plus glass thickness)?

I was thinking of using a plywood core (1" thick?) for the flat center sections of the windshield. What are your thoughts on that? Would it be too heavy if plywood core is used?

As always, any advice is much appreciated. I promise to take many pictures and post them!

THanks,

Vince

I am looking to fabricate a fiberglass windshield for my Sportfish model and i am looking for some recommendations on layup schedule. I know some here have fabricated their windshield themselves (as opposed to installing the Holmsey product). I have pulled molds off the existing windshield and am ready to start with my layup. I saw an old post by Spencer where he talked about 2 layers of 1/2 inch Divyncell and 1708 biaxial. How many layers of 1708 per side? Did you reinforce with plywood or any thicker sections or was the windsheild a uniform 1" thickness (plus glass thickness)?

I was thinking of using a plywood core (1" thick?) for the flat center sections of the windshield. What are your thoughts on that? Would it be too heavy if plywood core is used?

As always, any advice is much appreciated. I promise to take many pictures and post them!

THanks,

Vince

Re: Fiberglass Windshield Layup Schedule

Vince, When I made my cabin, I used one layer 3/4 Divynicell, two layers of 1708 Per side and one layer of kitty hair then I covered it with peel n ply release fabric, the kitty hair gives you something to grind on without getting into the 1708, pretty near one inch when all said and done. I used that layup for the walls the roof I made was two layers of 3/4 divnyicell then same layup schedule. BH

1966 31 Bahia Mar #316-512....8 years later..Resolute is now a reality..Builder to Boater..285 hours on the clocks..enjoying every minute..how many days till spring?

Re: Fiberglass Windshield Layup Schedule

Looks like a "rehoboth connection"....

Bob-Keep this stuff coming...its like school.....learning a lot from the posts. Already biult a lot of small items with the penske covered with 1708 from earlier "schooling". Please elaborate on the "kitty hair"? Thats a new one for me.

Bob-Keep this stuff coming...its like school.....learning a lot from the posts. Already biult a lot of small items with the penske covered with 1708 from earlier "schooling". Please elaborate on the "kitty hair"? Thats a new one for me.

Giff

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

Re: Fiberglass Windshield Layup Schedule

Basically Polyester resin based "bondo type" body filler with chopped fiberglass strands in it. Made by Evercoat and can't be used over epoxy. Bob, sure hope you didn't...."kitty hair"?

Br,

Patrick

Molon labe

Patrick

Molon labe

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

Re: Fiberglass Windshield Layup Schedule

Vince,

Tell me more about how you built your mould. That's the key to advising you on a layup schedule...

Tell me more about how you built your mould. That's the key to advising you on a layup schedule...

Br,

Patrick

Molon labe

Patrick

Molon labe

- Vince Luciani

- Senior Member

- Posts: 172

- Joined: Jul 1st, '06, 09:50

- Location: Rehoboth Beach, Delaware

Re: Fiberglass Windshield Layup Schedule

Capt Pat,

I built female molds by screwing down fiberglass sheet material from Home depot around the perimeter of the curved sections. I did this with the windshield still on the boat. Then I stiffened the sheet with wood stiffeners, fiberglassing, and bondo fill. I will post some pictures when I get them. So i intend to build the curved sections within the female mold that I built. My idea was to apply 2 layers of 1708, then epoxy my core material (foam or perhaps strips of plywood) to those 2 layers, and then capp it with two more layers of 1708. I will pop it from the mold and do some "rough" fairing before I install on the boat. I intend to break the whole windshield into 4 sections (two curved sections and two flat center sections). I will remove the old windshield frame and assemble all four sections separately. Then the fun job of fairing! That's my plan at least. I just am not sure about how much load is on that windshield section. It seems to me that it would be alot and I want to make sure I make it strong enough. Thanks for you help.

Below is one picture of the startings of my mold construction. I will get you more pictures this weekend.

I built female molds by screwing down fiberglass sheet material from Home depot around the perimeter of the curved sections. I did this with the windshield still on the boat. Then I stiffened the sheet with wood stiffeners, fiberglassing, and bondo fill. I will post some pictures when I get them. So i intend to build the curved sections within the female mold that I built. My idea was to apply 2 layers of 1708, then epoxy my core material (foam or perhaps strips of plywood) to those 2 layers, and then capp it with two more layers of 1708. I will pop it from the mold and do some "rough" fairing before I install on the boat. I intend to break the whole windshield into 4 sections (two curved sections and two flat center sections). I will remove the old windshield frame and assemble all four sections separately. Then the fun job of fairing! That's my plan at least. I just am not sure about how much load is on that windshield section. It seems to me that it would be alot and I want to make sure I make it strong enough. Thanks for you help.

Below is one picture of the startings of my mold construction. I will get you more pictures this weekend.

Re: Fiberglass Windshield Layup Schedule

While I cannot take credit of the windshield done on my 31 I, was there and watched the process, the guy overseeing the project was from merrit boat works,

1. the windshield was removed and the flybridge supported by 2x4

2. A thin veneer of wood was bent to follow the contour of the opening of the original windshield from the inside of the cabin for the whole windshield

3. the void areas were filled with a release pudy so glass could be layed, all areas were grinded down to glass

4. Athin layer of glass was layed followed by two layers of 1708, then diveyncell was wetted and layed in the flat areas, the corners of the windshield was then done with diveyncell that was cut into small squares with a backing to follow the contours

5. everything was wetted out and any voids filled with thickedend epoxy.

6. following two layers of 1708

7. lots of fairing followed

1. the windshield was removed and the flybridge supported by 2x4

2. A thin veneer of wood was bent to follow the contour of the opening of the original windshield from the inside of the cabin for the whole windshield

3. the void areas were filled with a release pudy so glass could be layed, all areas were grinded down to glass

4. Athin layer of glass was layed followed by two layers of 1708, then diveyncell was wetted and layed in the flat areas, the corners of the windshield was then done with diveyncell that was cut into small squares with a backing to follow the contours

5. everything was wetted out and any voids filled with thickedend epoxy.

6. following two layers of 1708

7. lots of fairing followed

- Vince Luciani

- Senior Member

- Posts: 172

- Joined: Jul 1st, '06, 09:50

- Location: Rehoboth Beach, Delaware

Re: Fiberglass Windshield Layup Schedule

Thanks Spencer! Would you say that the 1" thickness is plenty strong?

Re: Fiberglass Windshield Layup Schedule

yes, it is really strong,

I think there is some different shots of it being done on my photobucket account will try to post link

Good luck!

I think there is some different shots of it being done on my photobucket account will try to post link

Good luck!

- Vince Luciani

- Senior Member

- Posts: 172

- Joined: Jul 1st, '06, 09:50

- Location: Rehoboth Beach, Delaware

Re: Fiberglass Windshield Layup Schedule

Thanks again. I did look at the photos on your photobucket account!

Re: Fiberglass Windshield Layup Schedule

Pat, I only use epoxy, the kitty hair I meant, was the cloth that has just fibers in all different directions. BH

1966 31 Bahia Mar #316-512....8 years later..Resolute is now a reality..Builder to Boater..285 hours on the clocks..enjoying every minute..how many days till spring?

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

Re: Fiberglass Windshield Layup Schedule

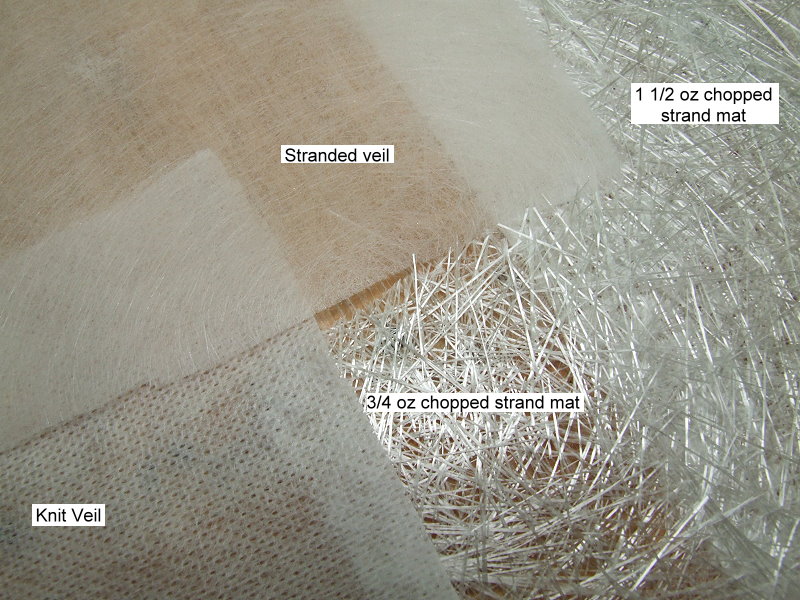

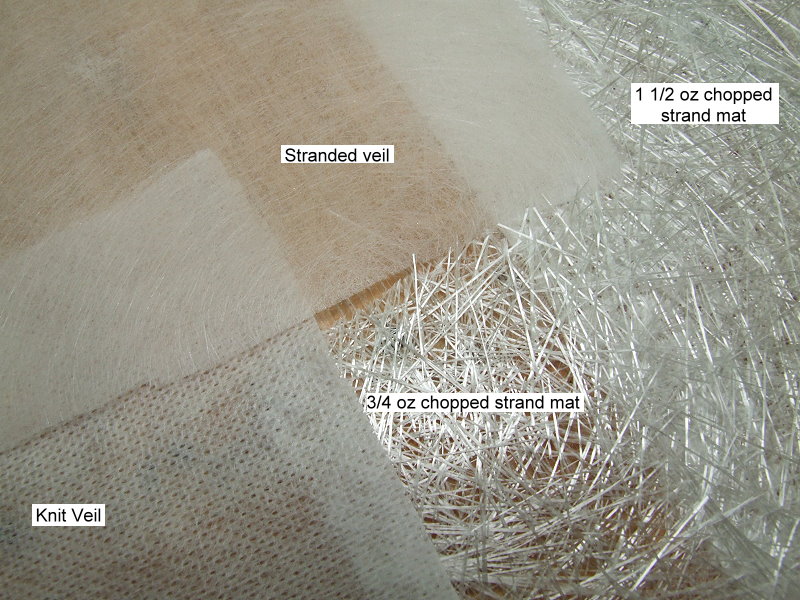

Great, you had me scared there! I think what you're calling "kitty hair" is what I call stranded or filamentous veil. Weighs about 0.10 oz per square yard.

Just in case somebody out there hasn't heard me before, ester resins have no adhesion value other than to their self and only within a short window of time. Epoxy sticks to cured ester resins, ester resins don't stick to epoxy...

Yes, you can make workable and dependable new ester resin modifications and repairs to old ester resin, but there are very special rules and procedures that must be followed to make it happen. And even then, it is not the same strength as is achieved by using epoxy.

Just in case somebody out there hasn't heard me before, ester resins have no adhesion value other than to their self and only within a short window of time. Epoxy sticks to cured ester resins, ester resins don't stick to epoxy...

Yes, you can make workable and dependable new ester resin modifications and repairs to old ester resin, but there are very special rules and procedures that must be followed to make it happen. And even then, it is not the same strength as is achieved by using epoxy.

Br,

Patrick

Molon labe

Patrick

Molon labe

- Vince Luciani

- Senior Member

- Posts: 172

- Joined: Jul 1st, '06, 09:50

- Location: Rehoboth Beach, Delaware

Re: Fiberglass Windshield Layup Schedule

Capt Pat and Bob,

I intend to use all epoxy resin also.

I intend to use all epoxy resin also.

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

Re: Fiberglass Windshield Layup Schedule

Vince,

Don't get me wrong, theres nothing wrong with using ester resin for NEW construction. As a matter of fact it's more advantageous; less expensive, faster, just as strong, easier clean up, and more fiberglass materials are designed for it. Most of the chopped and long strand mats are made with a styrene binder that dissolves when used with ester resin.

My points above are that you can't use polyester/vinylester resin as a secondary material over primary epoxy. None of the NEW construction that I produce is done in epoxy, it's all polyester. Any fairing necessary when fitting a part onto the boat is always, (by me at least), done with Awlfair, an epoxy fair compound.

Don't get me wrong, theres nothing wrong with using ester resin for NEW construction. As a matter of fact it's more advantageous; less expensive, faster, just as strong, easier clean up, and more fiberglass materials are designed for it. Most of the chopped and long strand mats are made with a styrene binder that dissolves when used with ester resin.

My points above are that you can't use polyester/vinylester resin as a secondary material over primary epoxy. None of the NEW construction that I produce is done in epoxy, it's all polyester. Any fairing necessary when fitting a part onto the boat is always, (by me at least), done with Awlfair, an epoxy fair compound.

Br,

Patrick

Molon labe

Patrick

Molon labe

- Vince Luciani

- Senior Member

- Posts: 172

- Joined: Jul 1st, '06, 09:50

- Location: Rehoboth Beach, Delaware

Re: Fiberglass Windshield Layup Schedule

I understand Capt Pat! So maybe i will fabricate my sections using polyester resin and then do all the installation to the boat and fairing using epoxy. Thanks,

Vince

Vince

Re: Fiberglass Windshield Layup Schedule

Vince the only drawback here appears to be after the job is over you still have to do something with the inside am I right or did I miss something .i used the vail over Biax on my cockpit floor from the captain's advise.a word to the wise make sure you have extra help to pull in all four directions the vail loves to ripple and on hot day you will be racing before the mix sets up.

capt.bob lico

bero13010473

bero13010473

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

Re: Fiberglass Windshield Layup Schedule

Bob,the vail loves to ripple

That reaction is usually a result of too much resin, allowing the veil to float in the excess resin. Squeeging out the excess resin will usually cure the problem.

Rather than draping the dry veil over the part and wetting after, wet the part evenly, lay the veil on the wetted part and use a roller to press the veil into the fresh resin. Brush in additional resin only to any un-wetted veil. Again the roller and squeegee are key tools. Never work ester resins in direct sunlight and/or in the heat of the day if it can be avoided.

Br,

Patrick

Molon labe

Patrick

Molon labe

- Vince Luciani

- Senior Member

- Posts: 172

- Joined: Jul 1st, '06, 09:50

- Location: Rehoboth Beach, Delaware

Re: Fiberglass Windshield Layup Schedule

Some more pics of my molds for the curved sections. Bob, I plan to do "rough" fairing of my pieces (both on the inside survace and outside surface) before i assemble on boat. But, yes I will have to fair on the inside after I assemble on the boat.

Re: Fiberglass Windshield Layup Schedule

I stand corrected thank you once again captain I really did struggle with the vail now I know ,like bob said great product for leveling and not sanding into biax. Ok Vince I figure you would have to get rid of the butt ugly inside of windshield somehow,can't wait to see finish product.

capt.bob lico

bero13010473

bero13010473

Re: Fiberglass Windshield Layup Schedule

Is the Holmsey item still available? That's what I used and thought it was a good product. Just wondering why people on going through the trouble to make their own molds....

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

Re: Fiberglass Windshield Layup Schedule

Beats me Craig... Yup, it's still available and other than a fairly minor quirky twist on the post side, it's the only way I'd go. But to each his own and I'd be the last alive to say that challenges aren't valuable teachers and I accept challenges daily, some out of my comfort range. I'd estimate that the materials alone to make up a set of molds would cost me more than Holmesy's windshield , forget the labor...Craig Mac wrote:Is the Holmsey item still available? That's what I used and thought it was a good product. Just wondering why people on going through the trouble to make their own molds.

Br,

Patrick

Molon labe

Patrick

Molon labe

- Vince Luciani

- Senior Member

- Posts: 172

- Joined: Jul 1st, '06, 09:50

- Location: Rehoboth Beach, Delaware

Re: Fiberglass Windshield Layup Schedule

Capt Pat,

I do like challenges! Besides I need something to keep me busy during the winter. I don't know what one of those Holmsey units cost, but I am thinking I am going to have about $600 in materials (not counting paint) when all is said and done. I will keep a tally and post when I am finished.

Do you see anything wrong with using pine 1x3's for the curved sections?

I do like challenges! Besides I need something to keep me busy during the winter. I don't know what one of those Holmsey units cost, but I am thinking I am going to have about $600 in materials (not counting paint) when all is said and done. I will keep a tally and post when I am finished.

Do you see anything wrong with using pine 1x3's for the curved sections?

Re: Fiberglass Windshield Layup Schedule

What is good about the Holmsey piece is that it is double skinned--so you have a finished surface for the interior as well.

A friend bought the mold from Glastech which had raw fiberglass on the inside.

A friend bought the mold from Glastech which had raw fiberglass on the inside.

Re: Fiberglass Windshield Layup Schedule

Craig I came to the same conclusion on the Holmsey windshield . The finish was beautiful on both sides but I wanted to add I took strength so I tookvv some advise from the captain and ordered my windshield with clear fir on top and bottom because my finished product was not just a "pretty face" on a FBC.when I put my windshield on it is by far the strongest part of the upper structure.i used 44 11/2" by 1/4" lag bolts tighten with socket wrench into harden epoxy also 20bolts in top very,very differcult to drill will angle of windshield.i used a special spring dive with bit in it to drill parallel to windshield. When finish the boat deck is now joined to the bridge as if one piece.able to slam into the face of a 12' wave if unavoidable.becomes totally waterproof also.by far the best upgrade you could possibly do to a FBC along with sealed side windows.phoenix would not make the boat writers list because it does not have 12 drink holders!,,, but she would hold her own in Oragon Inlet along side the coast guard doing there tests.

capt.bob lico

bero13010473

bero13010473

Who is online

Users browsing this forum: Bing [Bot] and 546 guests