Engine Alarms

Moderators: CaptPatrick, mike ohlstein, Bruce

-

Tony Meola

- Senior Member

- Posts: 7036

- Joined: Jun 29th, '06, 21:24

- Location: Hillsdale, New Jersey

- Contact:

Engine Alarms

On the 270 Recon Cummins, (same engine as the 250) do the engine alarms trigger off the sending unit or the guage. I am having a problem with one engine that is tripping the low oil pressure alarm when I idle down after running.

Running I get 60 lbs of pressure, when I start them first time I have 40 lbs at idle, but after they warm up the pressure drops. I am going to less than 5 lbs on the one engine and the alarm pops on and off. Trying to figure out if I need a new sending unit or have to replace the gauge.

Running I get 60 lbs of pressure, when I start them first time I have 40 lbs at idle, but after they warm up the pressure drops. I am going to less than 5 lbs on the one engine and the alarm pops on and off. Trying to figure out if I need a new sending unit or have to replace the gauge.

1975 FBC BERG1467-315

- In Memory Walter K

- Senior Member

- Posts: 2912

- Joined: Jun 30th, '06, 21:25

- Location: East Hampton LI, NY

- Contact:

-

Tony Meola

- Senior Member

- Posts: 7036

- Joined: Jun 29th, '06, 21:24

- Location: Hillsdale, New Jersey

- Contact:

Alarms trigger off a switch which can look similar to a guage sender but actualy close on high temp for water and low pressure for oil.

The oil pressure one will almost always be the smaller of the two on the oil side.

If your dropping to 5lbs indicated on the guage and the alarm goes off thats TWO indications that you have an oil pressure issue.

Stop and call your warrantee people ASAP.

The oil pressure one will almost always be the smaller of the two on the oil side.

If your dropping to 5lbs indicated on the guage and the alarm goes off thats TWO indications that you have an oil pressure issue.

Stop and call your warrantee people ASAP.

Speaking of alarm issues, I have one and no one on boatdiesel.com could answer, so I turn to the experts, where I should have come in the first place.

My Cummins 6BTA-300-s have the alarm circuit board with the puny inaudible buzzer. I had a raw-water hose blow off the other day and couldn't hear that damn buzzer with the engines rung up. Fortunately I caught it in time but . . .

So, with the alarm board connected to VDO Ocean gauges and not the original Cummins gauges I want to know if there is a way to bypass the buzzer on the board and connect to a loud bell. If not how do I go about connecting the engines to something that gets my attention.

My Cummins 6BTA-300-s have the alarm circuit board with the puny inaudible buzzer. I had a raw-water hose blow off the other day and couldn't hear that damn buzzer with the engines rung up. Fortunately I caught it in time but . . .

So, with the alarm board connected to VDO Ocean gauges and not the original Cummins gauges I want to know if there is a way to bypass the buzzer on the board and connect to a loud bell. If not how do I go about connecting the engines to something that gets my attention.

Mikey

3/18/1963 - -31-327 factory hardtop express, the only one left.

The difference between genius and stupidity is that genius has its limits.

-Albert Einstein

3/18/1963 - -31-327 factory hardtop express, the only one left.

The difference between genius and stupidity is that genius has its limits.

-Albert Einstein

- In Memory of Vicroy

- Senior Member

- Posts: 2340

- Joined: Jun 29th, '06, 09:19

- Location: Baton Rouge, LA

I was under the impression that on the 250/270 the circuit board triggers the alarm light & buzzer and not a hard switch, but could be wrong. I took a big wave over the f.b. years ago and soaked the panel causing all the alarms to go off....some CX got all but one, the low voltage alarm, to go off. Never have been able to get the low voltage one to go off and refuse to pay $300 for a dinky ass circuit board. I silenced the little do-nut looking buzzer on the circuit board by stuffing a plastic worm in it. My voltage is fine as verified by my voltmeters and the Garmin voltage read out. Crappy set up, that's all.

Mikey - you can use the current output to the idiot light to trip a relay that you can run a fire house bell thru if you so desire. Not sure how much amparage that wire puts out but it is probably not much so may need a Radio Shack relay with a 12v primary coil of low ampare, say 100 M.A. or so and the secondary contacts that will handle 10 amps or more.....a car horn relay may work too.

Remember that the Cummins 6Bs run very low oil pressure at idel warmed up so I'd put a mechanical gague on it before chasing my tail....mine show next to nothing on the gagues at idel hot.

UV

Mikey - you can use the current output to the idiot light to trip a relay that you can run a fire house bell thru if you so desire. Not sure how much amparage that wire puts out but it is probably not much so may need a Radio Shack relay with a 12v primary coil of low ampare, say 100 M.A. or so and the secondary contacts that will handle 10 amps or more.....a car horn relay may work too.

Remember that the Cummins 6Bs run very low oil pressure at idel warmed up so I'd put a mechanical gague on it before chasing my tail....mine show next to nothing on the gagues at idel hot.

UV

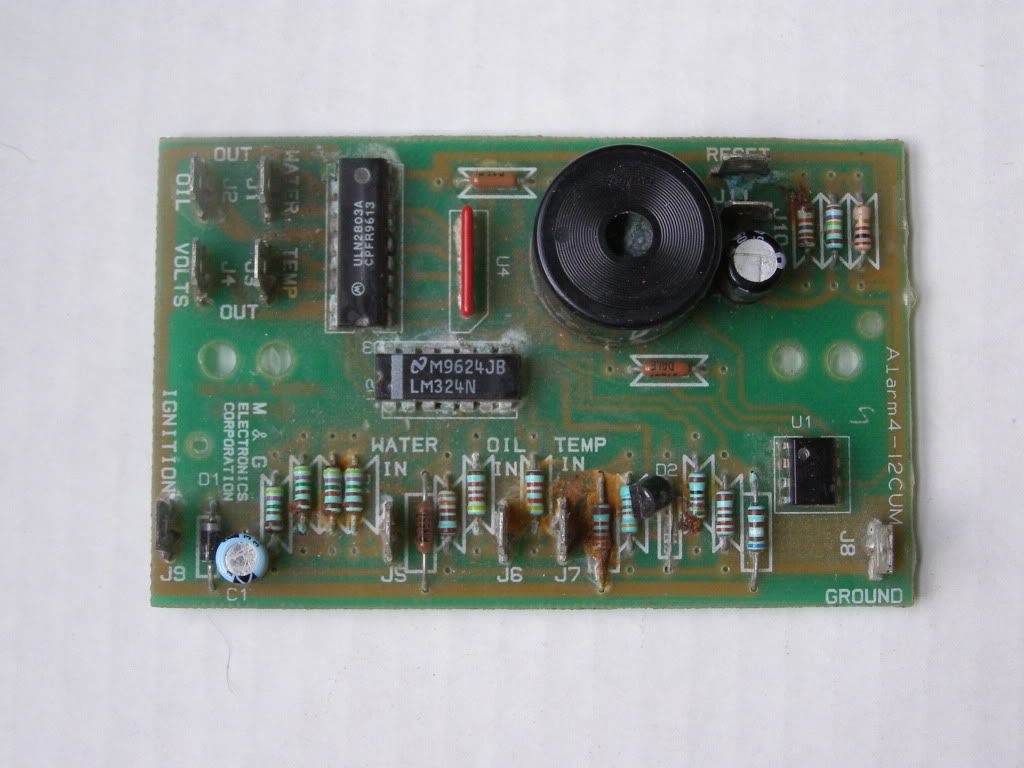

The B and C series wiring uses a circuit board on the alarm to prevent various alarm circuits from back feeding into each other using diodes to feed one alarm horn. Cummins calls it an electronic module.

Standard and optional alarms on them are oil, water, voltage, water in fuel, gear temp.

The alarm uses engine mounted switches for the oil pressure, water temp and trans temp switching the ground circuit for the alarm and the coresponding indicator lite to go off.

Mikey, yes you could add a large alarm bell to the system.

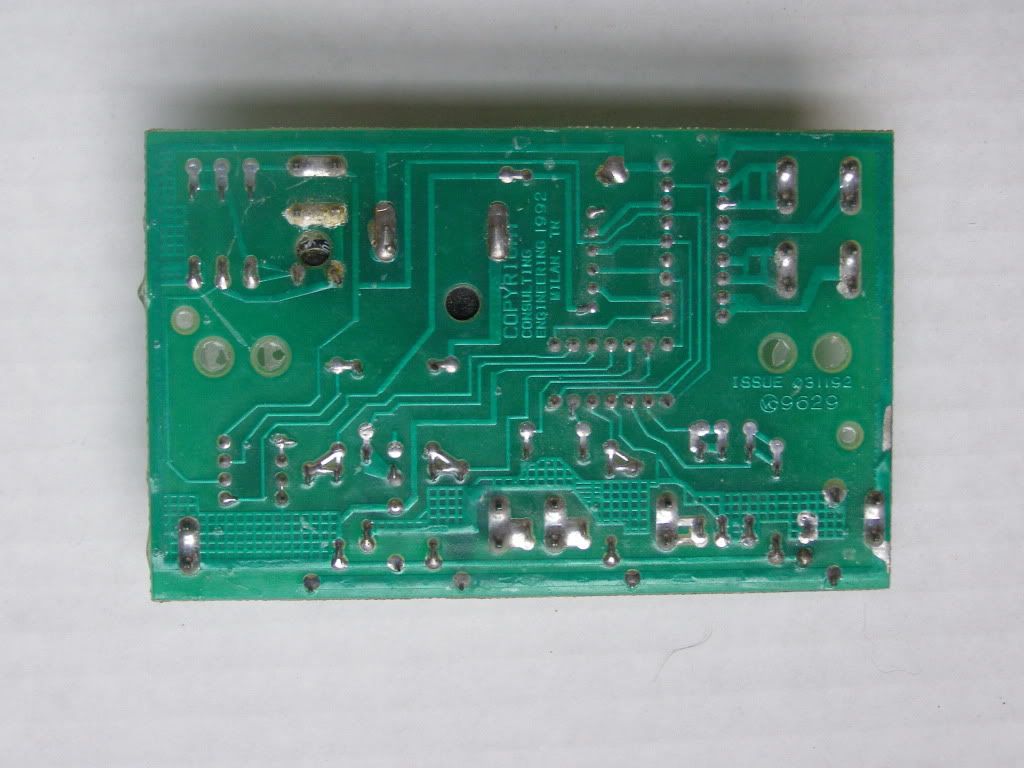

The only caveat is I don't have any reference, and without an alarm module in front of me, if someone could post a pic of one of the front and back I can probably tell on what if any limitations are to the cicuit that operates the factory piezo buzzer.

Therefore I can't determine whether a relay coil current of 100 milliamps or more would render the board dead. I've done this in the past on numerous Cummins alram panels but for the life of me I can't remember.

The relay, not solenoid but a relay is need like UV said to operate those 8" red alarm bells.

What you would do is have to solder a pair of leads that go to the same contact points as the factory piezo for the relay coil. That way when the piezo would go off it would operate the relay coil and power the bell.

Next you would need for a good solid ground and a + 12 switched off the key. This + would need a fuse that handles the bell current.

Wire the ground to one wire of the bell. Some bells I have seen are polarity sensitive so check to see if there is a + or - side. you wire it wrong and it will burn up.

The + wire fused would go to the feed side if marked of the relay. The + side of the bell would go to the load side of the relay.

One of those square relays from the auto parts store with spade terminals should work as long as the board can handle the coil current.

If you want to use one bell for both sides you can wire the plus side of each piezo horn circuit thru a diode so it doesn't feed back into the other engines circuit then wire that common point of the two diode ends to the relay coil terminal.

Standard and optional alarms on them are oil, water, voltage, water in fuel, gear temp.

The alarm uses engine mounted switches for the oil pressure, water temp and trans temp switching the ground circuit for the alarm and the coresponding indicator lite to go off.

Mikey, yes you could add a large alarm bell to the system.

The only caveat is I don't have any reference, and without an alarm module in front of me, if someone could post a pic of one of the front and back I can probably tell on what if any limitations are to the cicuit that operates the factory piezo buzzer.

Therefore I can't determine whether a relay coil current of 100 milliamps or more would render the board dead. I've done this in the past on numerous Cummins alram panels but for the life of me I can't remember.

The relay, not solenoid but a relay is need like UV said to operate those 8" red alarm bells.

What you would do is have to solder a pair of leads that go to the same contact points as the factory piezo for the relay coil. That way when the piezo would go off it would operate the relay coil and power the bell.

Next you would need for a good solid ground and a + 12 switched off the key. This + would need a fuse that handles the bell current.

Wire the ground to one wire of the bell. Some bells I have seen are polarity sensitive so check to see if there is a + or - side. you wire it wrong and it will burn up.

The + wire fused would go to the feed side if marked of the relay. The + side of the bell would go to the load side of the relay.

One of those square relays from the auto parts store with spade terminals should work as long as the board can handle the coil current.

If you want to use one bell for both sides you can wire the plus side of each piezo horn circuit thru a diode so it doesn't feed back into the other engines circuit then wire that common point of the two diode ends to the relay coil terminal.

- In Memory of Vicroy

- Senior Member

- Posts: 2340

- Joined: Jun 29th, '06, 09:19

- Location: Baton Rouge, LA

Looking for universal water temp alarm switches for my old Cummins 504's. I beleive 1/2" NPT. Any leads on a good sender. Saw Cole Hersee units but did not like the temp range choices. Thinking 210F is a good number. CH did not offer anything that i saw in that range.

Suggestions.

BTW, as far as alarms....I but the "dinner bell" down at engine level, and annoying buzzers up on the bridge. You won't miss an alarm on my boat....provided the thing goes off.

Suggestions.

BTW, as far as alarms....I but the "dinner bell" down at engine level, and annoying buzzers up on the bridge. You won't miss an alarm on my boat....provided the thing goes off.

Giff

-

Tony Meola

- Senior Member

- Posts: 7036

- Joined: Jun 29th, '06, 21:24

- Location: Hillsdale, New Jersey

- Contact:

tony take the boat out and bring engines to temp. when you come in bring boat down to 800rpm on both sides . ride for a couple minutes then down to to 700rpm for a few minutes then idle in and dock . tell me if the alarms go off.

mikey photo the back side ( the side facing the back of the engine) of the coolant expansion tank mounted on the front of engine. i will walk you thru the alarm situation.i am looking to see if you have a output block welded to the middle of expansion tank.cummins part numbers do not indicate first year of new design which have four outputs out of block.

mikey photo the back side ( the side facing the back of the engine) of the coolant expansion tank mounted on the front of engine. i will walk you thru the alarm situation.i am looking to see if you have a output block welded to the middle of expansion tank.cummins part numbers do not indicate first year of new design which have four outputs out of block.

capt.bob lico

bero13010473

bero13010473

Hey Bob are you talking about putting in another temp switch for the high heat to run the bell?

And since Tony is getting two indications of low oil pressure, I personaly wouldn't run the engine anymore till hi warrantee mechanic looked at the problem. Since they are remans, I wouldn't chance it.

Gplume,

Cummins uses switches rated at 205f =/- 3 for temp, 10 psi =/- 5% for oil and 11.6 vdc =/- 5% for voltage.

Try NAPA. Or get the b/c series switch.

And since Tony is getting two indications of low oil pressure, I personaly wouldn't run the engine anymore till hi warrantee mechanic looked at the problem. Since they are remans, I wouldn't chance it.

Gplume,

Cummins uses switches rated at 205f =/- 3 for temp, 10 psi =/- 5% for oil and 11.6 vdc =/- 5% for voltage.

Try NAPA. Or get the b/c series switch.

Damn son, clean that panel with some cx and a soft tooth brush with a lite touch first.

Now I remember after seeing it. The 180 milli amp draw of a standard 12 auto type relay pop'd the switching circuit for the horn after a little time on the first one I did.

What I did to correct the issue was use a smaller 12 milli amp relay to drive the coil of the larger relay for the horn.

I can either draw you up a schematic, BTW you'll need a soldering iron not a gun to do it, or send me both alarm panels and I'll combine them into a single feed for the alarm bell and build you a small circuit board.

Turn around time should be a week with priority from VA.

All you'll owe me will be for the two relays and a two pak of diodes + shipping. 20 to 30 bucks I recon.

If you rather do it yourself, I'll draw a schematic up.

Now I remember after seeing it. The 180 milli amp draw of a standard 12 auto type relay pop'd the switching circuit for the horn after a little time on the first one I did.

What I did to correct the issue was use a smaller 12 milli amp relay to drive the coil of the larger relay for the horn.

I can either draw you up a schematic, BTW you'll need a soldering iron not a gun to do it, or send me both alarm panels and I'll combine them into a single feed for the alarm bell and build you a small circuit board.

Turn around time should be a week with priority from VA.

All you'll owe me will be for the two relays and a two pak of diodes + shipping. 20 to 30 bucks I recon.

If you rather do it yourself, I'll draw a schematic up.

- In Memory Walter K

- Senior Member

- Posts: 2912

- Joined: Jun 30th, '06, 21:25

- Location: East Hampton LI, NY

- Contact:

- TailhookTom

- Senior Member

- Posts: 985

- Joined: Jul 3rd, '06, 14:12

O.K., Guys, Chill. By now you should know better. I'm as rabid about CX as Vic. This is a "cooked" board (probably from whatever moisture did that deed) that was on the starboard engine when I got them. I replaced it at installation. I CX all my electrical connections annually as instructed by our fearless (and always winning) leader. Anyway . . .

Bruce,

I would prefer sending them to you as I stink with a soldering iron or gun. I do many things well but that ain't one. Give me a snail mail address and I will remove them and pack'em up and let you have at them. I can either enclose a check or wait until you have an exact # and send it then. Let me know.

Bless you, my son. I owe you din-din . . . at least!

Bruce,

I would prefer sending them to you as I stink with a soldering iron or gun. I do many things well but that ain't one. Give me a snail mail address and I will remove them and pack'em up and let you have at them. I can either enclose a check or wait until you have an exact # and send it then. Let me know.

Bless you, my son. I owe you din-din . . . at least!

Mikey

3/18/1963 - -31-327 factory hardtop express, the only one left.

The difference between genius and stupidity is that genius has its limits.

-Albert Einstein

3/18/1963 - -31-327 factory hardtop express, the only one left.

The difference between genius and stupidity is that genius has its limits.

-Albert Einstein

well i guess i was ignored! ok for the rest of you bertram brothers here is how it is done; cummins put a welded 4 outlet block on the right side of coolant tank. two of the outlet are used and two have a 1/4 pipe thread plug in them. you are going to put a liquid level sending unit in plugged hole closest to centerline of engine . then you are going to route those two wires up the harness to the gauge . we will take power from the gauge lighting circuit and power a 6" bell (draws .5 amps). as soon as a hose breaks you will have instant notification .this is the weakest link in a cummins because they carry a small amount of coolant for a diesel.this is not in the books guys this is a trade secret!!!

capt.bob lico

bero13010473

bero13010473

bruce i know the oil pressure problem it will take a long post to explain i will wait then go into it in depth. 270 cummins remam. are absolutely not rebuilt . they are brand spanking new and the bosch 4100 injection pump is run through the assembly line twice. engine does not meet tier three or four standards and only used as a replacement for existing-------------bullsh-t actually a brilliant way of cummins playing catch me fu-k me with the feds a loophole if you will.

capt.bob lico

bero13010473

bero13010473

-

Tony Meola

- Senior Member

- Posts: 7036

- Joined: Jun 29th, '06, 21:24

- Location: Hillsdale, New Jersey

- Contact:

Bob

It's funny sometimes it does it sometimes it does not. When it does do it,the alarm comes on rings then goes off, comes back on again. I will probably call my mechanic tomorrow to see what he says. I find it strange that it is doing it. Can't beleive I am loosing pressure like that but hey anything is possible.

Not sure what coming down to 800 RPS the down to 700 then to 600 which is idle for me, does to keep it from going off other than cool the oil down a little bit.

It's funny sometimes it does it sometimes it does not. When it does do it,the alarm comes on rings then goes off, comes back on again. I will probably call my mechanic tomorrow to see what he says. I find it strange that it is doing it. Can't beleive I am loosing pressure like that but hey anything is possible.

Not sure what coming down to 800 RPS the down to 700 then to 600 which is idle for me, does to keep it from going off other than cool the oil down a little bit.

1975 FBC BERG1467-315

thanks bruce----b.t.w. i avoided a trip to air base in Scotland but may have to go to supreme allied command ( NATO) Belgium want to take my place?

tony your engines are 2006 i believe. they are the storm block and the rifle galley was enlarged as well as cam bearing bosses ,only problem is cummins did not compensate with increased in flow. i want you to bring the engine down in rpm with oil hot in increments from cruise speed to 1000 then to 800rpm then 700 rpm each time keep it there for a few minutes. when you come back to me with --------------hey the alarm did not go off!!!!! i will take you to step two ok. you are out of your two year warranty you are going to need a photo tact for step two so look to borrow one.

tony your engines are 2006 i believe. they are the storm block and the rifle galley was enlarged as well as cam bearing bosses ,only problem is cummins did not compensate with increased in flow. i want you to bring the engine down in rpm with oil hot in increments from cruise speed to 1000 then to 800rpm then 700 rpm each time keep it there for a few minutes. when you come back to me with --------------hey the alarm did not go off!!!!! i will take you to step two ok. you are out of your two year warranty you are going to need a photo tact for step two so look to borrow one.

capt.bob lico

bero13010473

bero13010473

Bob,

Wasn't ignoring you, but my problem was raw water not fresh/antifreeze. Also damned near died from the heat at seven this a.m. removing the alarm boards. Inside the boat, inside a boathouse was 110 degrees. Escaped with my life but wasn't willing to stay another minute or five to open the engine box and photograph the expansion tank.

Bruce,

They will be on their way this p.m. by UPS or Fed Ex. When done will I still be able to use the silencing button to stop the bell? Can I use one bell for both engines?

Wasn't ignoring you, but my problem was raw water not fresh/antifreeze. Also damned near died from the heat at seven this a.m. removing the alarm boards. Inside the boat, inside a boathouse was 110 degrees. Escaped with my life but wasn't willing to stay another minute or five to open the engine box and photograph the expansion tank.

Bruce,

They will be on their way this p.m. by UPS or Fed Ex. When done will I still be able to use the silencing button to stop the bell? Can I use one bell for both engines?

Mikey

3/18/1963 - -31-327 factory hardtop express, the only one left.

The difference between genius and stupidity is that genius has its limits.

-Albert Einstein

3/18/1963 - -31-327 factory hardtop express, the only one left.

The difference between genius and stupidity is that genius has its limits.

-Albert Einstein

mikey i just wanted to post that coolant level sensor because that is by far the most dangerous situation that can happen to a cummins 6bta. raw water problem like leaking hose, raw water impeller, or clogged thru hull give you a little time as the temperature slowly starts to rise and set off alarms. on the other hand there is very little coolant in comparison and rapid loss will destroy the engine in a minute, no kidding. number 6 cylinder will melt in a minute without coolant . thats why i devise a cheap but bulletproof fix .you will hear that bell trust me! a cummins engine harness contains two spare wire mark pink and pink with black tracer the are used if you wanted to have a gauge for trans. oil temp. in addition to the trans oil pressure . you can use these two wires for coolant level if you so please.

when tony gets back to me ( i assume the bussers are going off when he comes down off plane and pulls back to idle back in gear with engine oil hot. i was not giving him the go ahead to use boat if oil pressure is low beyond 700 rpm. just making this clear!!!

when tony gets back to me ( i assume the bussers are going off when he comes down off plane and pulls back to idle back in gear with engine oil hot. i was not giving him the go ahead to use boat if oil pressure is low beyond 700 rpm. just making this clear!!!

capt.bob lico

bero13010473

bero13010473

-

Tony Meola

- Senior Member

- Posts: 7036

- Joined: Jun 29th, '06, 21:24

- Location: Hillsdale, New Jersey

- Contact:

Bruce

I take your advice very seriously. Trust me on that. I already called the dealer. Good guy, great mechanic. He is going to take a look for me., he said that since the alarm is going on and off at idle that it could be the sending unit. But we will find out.

Bob

That is right. I only have the issue under 700 RPS. I have like 60lbs of pressure normally. The issue is runnig at cruise, then come down to idle and then it is about 5 minutes to the dock. It is only the port engine that does it. Funny, the alarm kicks on then goes off then comes back on.

Funny I was thinking about your suggestion of slowing down gradually. The first time it happened, we took her out for a run, ran her for about an hour and headed up the Toms River to see the sites. As I got down river, I was gradually coming down in speed. I did not look at the RPS's but I know i was just off plane for a while, then down a little more than more again due to boat traffic. Then I got to a point that I went ot straight idle for about 15 minutes. No problem. Ran back up river to head for the barn. About a 30 minute run in total, then when I came off a plane, I was idling for about 5 minutes when the alarm kicked in. I hit the reset and it stopped and then came back on after about a minute.

So I may have already tried out your approach without paying attention. Lets see what we find.

I take your advice very seriously. Trust me on that. I already called the dealer. Good guy, great mechanic. He is going to take a look for me., he said that since the alarm is going on and off at idle that it could be the sending unit. But we will find out.

Bob

That is right. I only have the issue under 700 RPS. I have like 60lbs of pressure normally. The issue is runnig at cruise, then come down to idle and then it is about 5 minutes to the dock. It is only the port engine that does it. Funny, the alarm kicks on then goes off then comes back on.

Funny I was thinking about your suggestion of slowing down gradually. The first time it happened, we took her out for a run, ran her for about an hour and headed up the Toms River to see the sites. As I got down river, I was gradually coming down in speed. I did not look at the RPS's but I know i was just off plane for a while, then down a little more than more again due to boat traffic. Then I got to a point that I went ot straight idle for about 15 minutes. No problem. Ran back up river to head for the barn. About a 30 minute run in total, then when I came off a plane, I was idling for about 5 minutes when the alarm kicked in. I hit the reset and it stopped and then came back on after about a minute.

So I may have already tried out your approach without paying attention. Lets see what we find.

1975 FBC BERG1467-315

your mechanic will find nothing wrong with gauge. make sure you have two new fleetguard LF3894 oil filters , change oil to 20-50 mobil dulvac . use photo tact and 5/16" wrench on idle adjustment screw and bring idle speed to 635rpm on each engine------------relax and have a couple of beers games over!!

capt.bob lico

bero13010473

bero13010473

-

Tony Meola

- Senior Member

- Posts: 7036

- Joined: Jun 29th, '06, 21:24

- Location: Hillsdale, New Jersey

- Contact:

If the alarm is going off AND the guage reads 5lbs, then thats two indications of low oil pressure. If you only had one, then a suspect switch would be first thing to check.

Funny how the other engine doesn't do it, yet the cure suggested is a heavier oil which suggests bearing clearance issues, problems with oil pump or relief spring or blockage.

I also never saw a Cummins idle low enough before stalling to trigger low oil pressure.

But I guess these might be issues with the reman units.

I can't seem to find anywhere in any manuals I have that Cummins recomends anything but a rated 15w40. Maybe in a severe commercial HD application I'd use a heavier oil but I don't think that applies to you.

Funny how the other engine doesn't do it, yet the cure suggested is a heavier oil which suggests bearing clearance issues, problems with oil pump or relief spring or blockage.

I also never saw a Cummins idle low enough before stalling to trigger low oil pressure.

But I guess these might be issues with the reman units.

I can't seem to find anywhere in any manuals I have that Cummins recomends anything but a rated 15w40. Maybe in a severe commercial HD application I'd use a heavier oil but I don't think that applies to you.

cummins design the new storm block with a future of tier 3& 4 compliance with a hell of a lot more hp . they made the camshaft journals 1/4" bigger along with galleries than applied new heads with commonrail injection thus the qsb era begins and 400 hp plus same short block as tony`s. so they used the newest edition of the mechanical heads dated 2006 and the bosch 4100 injection. they should have changed the gear ratio in the remans. because they put the same amount of oil at idle thru a larger diameter oil gallery, not so on qsb---- differant configuration.you can put a photo tact on engine and oil pressure jumps with as little as 15 rpm added.new oil no problem 15-40wt. old oil hot with reduced viscosity at idle speed if you just come off cruise will set one alarm off the differants between engines may be 1 pound but the senting unit will trigger that alarm.100 degree weather and oil mention above will do it. yes go with the 20-50wt under those condition so that two pound differance will keep you at 7 lbs or more needless to say this does not apply to use in the North pole.you will not find any publications from cummins nor do they mention remans. cummins made ALL remans from brand new as a matter of fact my block date code is three months older then built code date. the same exact two year warr. as qsb.

ok in retropect you could play with spring relief pressure or oil pump gear ratio or leave well enough alone provided the pressure is normal at all engine speeds and pressure is normal at factory spec. of 40lbs at 160 degree f oil temperature. engine idle speed 550rpm to 650rpm this is factory reman. specs and this is why i suggested bump the idle because tony`s indicated normal oil pressure above low idle in gear.

ok in retropect you could play with spring relief pressure or oil pump gear ratio or leave well enough alone provided the pressure is normal at all engine speeds and pressure is normal at factory spec. of 40lbs at 160 degree f oil temperature. engine idle speed 550rpm to 650rpm this is factory reman. specs and this is why i suggested bump the idle because tony`s indicated normal oil pressure above low idle in gear.

capt.bob lico

bero13010473

bero13010473

-

Tony Meola

- Senior Member

- Posts: 7036

- Joined: Jun 29th, '06, 21:24

- Location: Hillsdale, New Jersey

- Contact:

Did not make it to the boat today. I will see what the Cummins Mech says. Maybe I need to get more air into the engine box's. It gets pretty warm in under those box's.

In any event, normal pressure once I push the throttle up a little. Could be the difference in the tolerance of the sending units who knows. But we will figure it out.

My fear is that if it turns out to be the oil thining out, then what is happening at cruise. Even with normal oil pressure, if the oil is thinning, is it doing it's job.

In any event, normal pressure once I push the throttle up a little. Could be the difference in the tolerance of the sending units who knows. But we will figure it out.

My fear is that if it turns out to be the oil thining out, then what is happening at cruise. Even with normal oil pressure, if the oil is thinning, is it doing it's job.

1975 FBC BERG1467-315

i should add something to this post. our boat diesel /gas engine lubricating oil are subjected to far more heat than if the same powerplant were placed in truck with ambient air passing over the oil pans. mercruiser uses a brass salt water cooled oil cooler that would be the best in terms off effect with 75 degree water cooling 280 degree oil however any cooling with raw water has its design faults . yanmar uses a raw water cooled oil cooler never a problem. cummins uses a 4"x 4" cooler inserted in the engine coolant at 190 degrees running temperature, not nearly close to what is needed to keep engine oil from breaking down into piss! now i am sure is bruce had cummins in his boat he would do the oil plumbing thing and utilize yanmar or similar raw water cooled oil cooler.needless to say the raw water should be screened due to seaweed screwing up the small diameter tubes in the oil cooler. either way that pretty new 15-30 wt oil you put in those cummins turn to sh-t real quick however no problem in a truck. cummins has over 1.4 million 6bt out there so they are not to concerned for those few with mechanical marine version. personally i have used all kinds of tricks to keep cool air moving in the engine compartment even a rod holder in gunnel next to engine ,being at the top of engine you should feel the hot air coming out off that forward rod holder! in lite of this post and REALITY you can see why i suggest 20-50 wt in the heat of the summer for cummins 6bta.

capt.bob lico

bero13010473

bero13010473

- scenarioL113

- Senior Member

- Posts: 690

- Joined: May 31st, '08, 09:00

- Location: Massapequa Park, NY

I was going to suggest inspecting the oil spring/plunger unit that is in the oil cooler housing.

Bruce mentioned that in his last post, I had a similar issue with one of my 4BT's with low oil pressure @ idle.

My gut tells me that your alarm and gauge senders are correct.

Make sure your idle is set correctly at what cummins says it is supposed to be. You would be surprised how much a difference in 50 to 100 rpms can make at idle on oil pressure. The difference would prob be less on a brand new engine but if you got some hours on it you could have some wear in the bearings.

The spring / plunger unit gets a polished mark on it that can look good by eye but may be worn and not allowing the unit to work properly and allowing too low a PSI @ idle.

It is a very inexpensive fix and even if its not your problem it wont hurt to replace it.

I replaced mine and saw approximately a 4 to 5 PSI difference @ idle. If your idle is 10PSI warmed up you will be good to go and have piece of mind.

With that said LOW PSI is something that should be monitored VERY CLOSELY.

You can temporarily hook up an inexpensive MECHANICAL oil pressure gauge right off the block to verify your electrical senders. My senders were balls on accurate with the mechanical gauge.

Bruce mentioned that in his last post, I had a similar issue with one of my 4BT's with low oil pressure @ idle.

My gut tells me that your alarm and gauge senders are correct.

Make sure your idle is set correctly at what cummins says it is supposed to be. You would be surprised how much a difference in 50 to 100 rpms can make at idle on oil pressure. The difference would prob be less on a brand new engine but if you got some hours on it you could have some wear in the bearings.

The spring / plunger unit gets a polished mark on it that can look good by eye but may be worn and not allowing the unit to work properly and allowing too low a PSI @ idle.

It is a very inexpensive fix and even if its not your problem it wont hurt to replace it.

I replaced mine and saw approximately a 4 to 5 PSI difference @ idle. If your idle is 10PSI warmed up you will be good to go and have piece of mind.

With that said LOW PSI is something that should be monitored VERY CLOSELY.

You can temporarily hook up an inexpensive MECHANICAL oil pressure gauge right off the block to verify your electrical senders. My senders were balls on accurate with the mechanical gauge.

1971 28 Bertram

4BT Cummins

Frank

9-11-01 NEVER FORGET

4BT Cummins

Frank

9-11-01 NEVER FORGET

-

Tony Meola

- Senior Member

- Posts: 7036

- Joined: Jun 29th, '06, 21:24

- Location: Hillsdale, New Jersey

- Contact:

I am going to get a photo tach and check the RPM's on both engines. I see Sears sells one for about 26 bucks. Probably not the real high end type of tach but I am sure close enough for government work.

It is possible that the Starboard engine idles a little higher thus no alarm. Will not hurt to check.

The Cummins dealer will be taking a look also, so lets see what we get.

I do agree with Bob, gets hot under those box's. I can see it turning that 15-40 to the consistency of water real quick. I get good pressure once I bump up the engines so it can't be thinning out completely.

It is possible that the Starboard engine idles a little higher thus no alarm. Will not hurt to check.

The Cummins dealer will be taking a look also, so lets see what we get.

I do agree with Bob, gets hot under those box's. I can see it turning that 15-40 to the consistency of water real quick. I get good pressure once I bump up the engines so it can't be thinning out completely.

1975 FBC BERG1467-315

no tony not completely but down to 15wt but if it gets some hours at high temp not great. tony hot oil is a factor since the beginning of racing. from increasing oil pan size to raw water coolers to dry sump on some offshore race boats. tony how many hours on your engines?

i looked rather silly back in the office with #2 man at metro (northeast distributor for cummins) he showed me the first delivery of remans. so i look it over and notice all the lastest and greatest cummins updates . i began with " what did you do go to every junkyard picking up blocks" he said you do think we would warranty a rebuild with the come-back labor you guys charge! "take another look"--------------damn i started laughing--- HOODWINKING the feds! i notice the webs on the side of block ,a storm block!!! " nah we just rebuilt a thousand two month old blocks with thousand of hours on them. then i realize you need the bosses in the storm block for all the updates and felt a little stupid . i figure this was the way to go while it lasted .so mr P hooked me up with a pair of 330hp. lesson learned" the obvious is not always what you see and hear"

i looked rather silly back in the office with #2 man at metro (northeast distributor for cummins) he showed me the first delivery of remans. so i look it over and notice all the lastest and greatest cummins updates . i began with " what did you do go to every junkyard picking up blocks" he said you do think we would warranty a rebuild with the come-back labor you guys charge! "take another look"--------------damn i started laughing--- HOODWINKING the feds! i notice the webs on the side of block ,a storm block!!! " nah we just rebuilt a thousand two month old blocks with thousand of hours on them. then i realize you need the bosses in the storm block for all the updates and felt a little stupid . i figure this was the way to go while it lasted .so mr P hooked me up with a pair of 330hp. lesson learned" the obvious is not always what you see and hear"

capt.bob lico

bero13010473

bero13010473

-

Tony Meola

- Senior Member

- Posts: 7036

- Joined: Jun 29th, '06, 21:24

- Location: Hillsdale, New Jersey

- Contact:

Bob

Since I have been doing a lot of work since the repower, and really last summer waas the first I could really use it due to work we had to clean up and I got in real late last year, my hours are light right now. Only 25. But I am startign to use it more this summer since I am pretty much all cuaght up on the repower work and adjustments.

The oil in it only has about 10 hours on it. So I am suprised I am having issues with it thinning out so soon.

Since I have been doing a lot of work since the repower, and really last summer waas the first I could really use it due to work we had to clean up and I got in real late last year, my hours are light right now. Only 25. But I am startign to use it more this summer since I am pretty much all cuaght up on the repower work and adjustments.

The oil in it only has about 10 hours on it. So I am suprised I am having issues with it thinning out so soon.

1975 FBC BERG1467-315

- In Memory Walter K

- Senior Member

- Posts: 2912

- Joined: Jun 30th, '06, 21:25

- Location: East Hampton LI, NY

- Contact:

- In Memory of Vicroy

- Senior Member

- Posts: 2340

- Joined: Jun 29th, '06, 09:19

- Location: Baton Rouge, LA

If you have a waranty, by all means get them to look at it.....BUT....do as Rawleigh suggests and put a mechanical gague on it and REMEMBER that the 6B Cummins engines are famous (or infamous) for low oil pressure when warm at idle. Mine show just off the pegs. The best Cummins mechanic I ever used, a guy named Walter with Cummins Mid-South in New Orleans, told me the engines were designed with a lot of clearance on the bearings to allow them to be started in very cold climates and that low oil pressure at idle was totally normal.

Mine have thousands of hours and have shown the same low idle pressures from the get go. And read the Cummins study they did on motor oils back in the early 90s that show that 15W40 oil is the best and reduces the oil consumption to near zero. The book oil change interval is 250 hours. I have always changed mine at 100-125 hours and neither engine uses ANY oil up to about 100 hours then begins to use a little....at 125 hours I will have added less than a quart per engine.

Be careful you don't chase your tail 0n this issue - but check the actual pressures with a mechanical gague. You might also look at the numerous threads on boatdiesel.com on the subject of 6B low oil pressure.

UV

Mine have thousands of hours and have shown the same low idle pressures from the get go. And read the Cummins study they did on motor oils back in the early 90s that show that 15W40 oil is the best and reduces the oil consumption to near zero. The book oil change interval is 250 hours. I have always changed mine at 100-125 hours and neither engine uses ANY oil up to about 100 hours then begins to use a little....at 125 hours I will have added less than a quart per engine.

Be careful you don't chase your tail 0n this issue - but check the actual pressures with a mechanical gague. You might also look at the numerous threads on boatdiesel.com on the subject of 6B low oil pressure.

UV

Who is online

Users browsing this forum: No registered users and 162 guests