spenting the next 3 months reinventing the wheel

Moderators: CaptPatrick, mike ohlstein, Bruce

carl i hear what your saying but both me and captain patrick and many others love the look of them .go back to the bridge photo on page 2 of this thread . the rybo style pod is my kind of bertram a real class act that belongs on a 31 bertram. the photo that john supply of his helm area shows the cut away area where he mounted the bell .that wall is were i will mount the bell crank so would need a 90 degree angle bracket . the other side of the wall is loaded from port to starboard with auto pilot hydralic pump, auto pilot computor,sonar dsm, electrical distributon terminals for insolation and large ground bar .with mutible termination blocks from smart heading sensor outputs (nmea/ray talk/gps )this entire area is filled but easily accessible from drop down access doors in cabin ceiling.i made a point of mentioning this because it is a great place to keep electrical / electronic termination/computers clean and dry under all conditions .you will get to test the boat at greenport. trust me at wot you will not forget it!!!

capt.bob lico

bero13010473

bero13010473

Bob,

As a last resort I called RG Rollins, Solo 2 @ 253.588.9978, asked for tech support... explained the problem and I was told the Shift Side of the Control has 1-3/8" travel and the Throttle Side has 2-1/4" travel.

- If that's the case give them cables a switch.

- If you do have 1-3/8 travel on both sides lets get them taken care of so you get the 2-1/4" travel.

I'd so much rather see a simple clean install.

As a last resort I called RG Rollins, Solo 2 @ 253.588.9978, asked for tech support... explained the problem and I was told the Shift Side of the Control has 1-3/8" travel and the Throttle Side has 2-1/4" travel.

- If that's the case give them cables a switch.

- If you do have 1-3/8 travel on both sides lets get them taken care of so you get the 2-1/4" travel.

I'd so much rather see a simple clean install.

sim right now is is cable as shown on page 2 of this thread if i put thottle cable on shift and vice versa there is that built in time delay in reverse where by helm goes into reverse then further movement of single lever control will start to increase rpm .i don`t understand how you could reverse cables to get by this problem?

capt.bob lico

bero13010473

bero13010473

Bob, I see your point about swapping the cables.

More importantly, what I see from this last drawing is adjustment.

If the Control needs to be adjusted correctly, that means it can also be adjusted incorrectly.

So how to adjust correctly...No clue, I do not know the Control, but would venture to guess it's a timing issue with the rack. He was quite sure the travel is 2-1/4" on the Solo 2.

It's the middle of Winter, so if your not up to dealing with this, maybe remove the Control, pack it up and send back to RG Rollins and have them adjust. Gives them some time to work on it and get it back to you before Spring.

Or

Offer still stands, if you want I'm not all that far from you, I'd be willing to come out and take a look at it for you. Or you could always come here. Sometimes fresh eyes can do wonders...and if I fix it, you can just send Capt Pat a donation. I'll even sweeten the pot, I'll match your donation...I owe for the last fund raiser as it is...

My opinion is we can always make up that mechanical rack, but if it were me...I'd try to get it done right at the Control. You don't really want to put K-Mart tires on a Porsche...

More importantly, what I see from this last drawing is adjustment.

If the Control needs to be adjusted correctly, that means it can also be adjusted incorrectly.

So how to adjust correctly...No clue, I do not know the Control, but would venture to guess it's a timing issue with the rack. He was quite sure the travel is 2-1/4" on the Solo 2.

It's the middle of Winter, so if your not up to dealing with this, maybe remove the Control, pack it up and send back to RG Rollins and have them adjust. Gives them some time to work on it and get it back to you before Spring.

Or

Offer still stands, if you want I'm not all that far from you, I'd be willing to come out and take a look at it for you. Or you could always come here. Sometimes fresh eyes can do wonders...and if I fix it, you can just send Capt Pat a donation. I'll even sweeten the pot, I'll match your donation...I owe for the last fund raiser as it is...

My opinion is we can always make up that mechanical rack, but if it were me...I'd try to get it done right at the Control. You don't really want to put K-Mart tires on a Porsche...

rocky once again i thank you for your input. lets go back to page two where i posted the diagram of the shift lever of the solo control notice the 13/8" travel now lets look at the thottle lever; i am going to cry foul by changing from thottle lever to shift lever the condition is even worst (less travel) what do you think. i feel they gave brother sim the run around.

capt.bob lico

bero13010473

bero13010473

Hi Bob, no problem with helping you guys, we'll get this thing resolved.

Looking at the installation manual, it sure looks like your total throw for the throttle is NOT 2 1/4" at all. I don't understand why techline would tell anyone this series has more than 1 3/4", unless this manual doesn't pertain to YOUR control, or is Japanese translated information. (You would think HarleyD. parts are made in U.S. too). If they are certain this control is 2 1/4", than what Carl said about sending it to them seems like the next step, hate to say I know you said they're a pain to R&R, BUT...

I agree with you Carl, simpler the better before absolutely having to go the plate option, though it is viable.

Ask them to send a spec sheet first?

Looking at the installation manual, it sure looks like your total throw for the throttle is NOT 2 1/4" at all. I don't understand why techline would tell anyone this series has more than 1 3/4", unless this manual doesn't pertain to YOUR control, or is Japanese translated information. (You would think HarleyD. parts are made in U.S. too). If they are certain this control is 2 1/4", than what Carl said about sending it to them seems like the next step, hate to say I know you said they're a pain to R&R, BUT...

I agree with you Carl, simpler the better before absolutely having to go the plate option, though it is viable.

Ask them to send a spec sheet first?

Bob, can you email me the entire installation manual? carl@simachine.com

Is there a model number, serial number any other information?

Something is definitely off here, I know what I asked the RG Rollins tech and what you are showing me does not jive...

I do not care who is wrong, you, me or RG I would just like to get this taken care of...if we have to make the "Rocky Design" we still have time.

Bob, on the first call I got thru the other day. Yesterday when I called back about the Solo II, I just got voice mail, sound familiar? I'll keep calling till I get a one on one again.

Is there a model number, serial number any other information?

Something is definitely off here, I know what I asked the RG Rollins tech and what you are showing me does not jive...

I do not care who is wrong, you, me or RG I would just like to get this taken care of...if we have to make the "Rocky Design" we still have time.

Bob, on the first call I got thru the other day. Yesterday when I called back about the Solo II, I just got voice mail, sound familiar? I'll keep calling till I get a one on one again.

- Brewster Minton

- Senior Member

- Posts: 1795

- Joined: Jun 30th, '06, 07:44

- Location: Hampton Bays NY

- Contact:

- In Memory Walter K

- Senior Member

- Posts: 2912

- Joined: Jun 30th, '06, 21:25

- Location: East Hampton LI, NY

- Contact:

Bob, Sim ,Rocky, nice job working that out...a little grind here a shim there...the granite counter top makes up for the paper arrow Bob...BH

1966 31 Bahia Mar #316-512....8 years later..Resolute is now a reality..Builder to Boater..285 hours on the clocks..enjoying every minute..how many days till spring?

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

Bob, I use PhotoImpact for all of my graphics and photo editing... Corel has a limited time sale going on for the same version that I use. Normally $70, on sale for $20...bob lico wrote:my home computer does not have the software, so i cannot make the arrows like the captain .

PhotoImpact X3

capt. patrick i always wonder what software you were using to put those marks on photoes and that sure is inexpensive. thats what you get when you hang out with mechanics.they use computers in a totally diferant application especially outboard 4/strokes.i grew up and was educated in a world without computers (sliderule) so when i ask these questions i get a blank look.

capt.bob lico

bero13010473

bero13010473

Way to go Bob and Carl! So I take it the manufacturer never could supply a different cam plate? Sounds like quite a few folks are going to follow this fix, thats great. I myself have been extremely busy with guess what, Toyota accelerator pedals! The news is just amazing how much they can blow out of proportion things. Anyway, great to see this thing work out.

No more complaints from the ladies and worrying about your prop in the strut Bob?!!!

No more complaints from the ladies and worrying about your prop in the strut Bob?!!!

Bob did the whole nine yards of the fix on this...only credit I deserve is giving Bob a little prodding and dealing with the manufacturer.

As it turns out the manufacture did not help resolve the situation, but they tried and did offer several possible solutions. They where also concerned enough to call back to see if any progress had been made.

They now know what was done to rectify the problem. and while they will not admit this was the correct solution, they do stand behind the fact the unit should develop 2-1/2" of forward throw. If yours does not, give them a call, you'll have to pick up the shipping, but they will correct at no charge.

RG Rollins Co. 253.588.9978. Ask for Harry.

They are on the West Coast, so call mid afternoon.

Carl

As it turns out the manufacture did not help resolve the situation, but they tried and did offer several possible solutions. They where also concerned enough to call back to see if any progress had been made.

They now know what was done to rectify the problem. and while they will not admit this was the correct solution, they do stand behind the fact the unit should develop 2-1/2" of forward throw. If yours does not, give them a call, you'll have to pick up the shipping, but they will correct at no charge.

RG Rollins Co. 253.588.9978. Ask for Harry.

They are on the West Coast, so call mid afternoon.

Carl

- In Memory Walter K

- Senior Member

- Posts: 2912

- Joined: Jun 30th, '06, 21:25

- Location: East Hampton LI, NY

- Contact:

Bravo Bob! It is obvious from all I have read, that you were not the only one that suffered from the same problem (despite what the manufacturer's claims were about their own product). Your solution and the great pictures of the solution you have provided should be patented and sold back to the manufacturer. Walter

-

Tony Meola

- Senior Member

- Posts: 7120

- Joined: Jun 29th, '06, 21:24

- Location: Hillsdale, New Jersey

- Contact:

Bob

Move quick on tht patent. Don't do what my father in law did years ago. He had a 20 foot boat with an OMC stern drive unit. He was frustrated trying to get oil in the unit, and this was before they made the pump that goes in the stern drive gearcase oil can. He was an engineer so he designed a pump and had it built in the machine shop at work. He went to see a patent attorney and decided it was too much money to spend at the time, so he sent his design to OMC. They told him it was not feasable cast wise and blew him off. About two years later guess what OMC makes to put oil in the stern drive unit.

He is 86 now and still kicking himself.

Move quick on tht patent. Don't do what my father in law did years ago. He had a 20 foot boat with an OMC stern drive unit. He was frustrated trying to get oil in the unit, and this was before they made the pump that goes in the stern drive gearcase oil can. He was an engineer so he designed a pump and had it built in the machine shop at work. He went to see a patent attorney and decided it was too much money to spend at the time, so he sent his design to OMC. They told him it was not feasable cast wise and blew him off. About two years later guess what OMC makes to put oil in the stern drive unit.

He is 86 now and still kicking himself.

- Capt.Frank

- Senior Member

- Posts: 641

- Joined: Jun 29th, '06, 21:20

- Location: Kill Devil Hills,NC

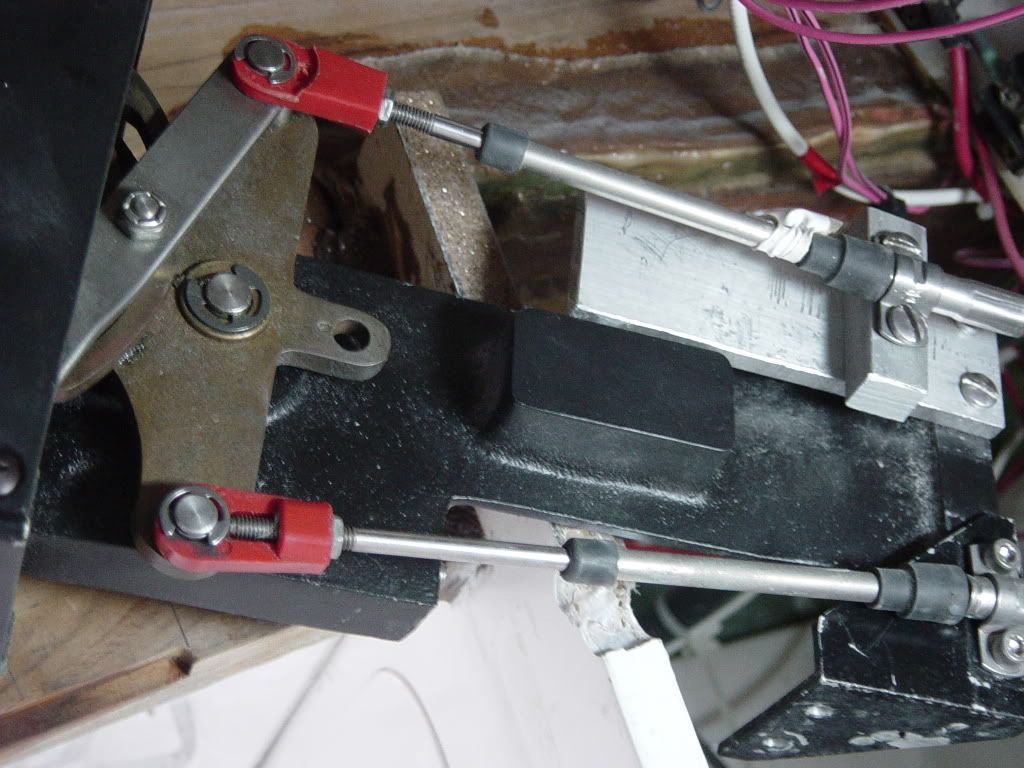

i had to grind the cam ,hold engine throttle lever in wot. position ,mark template of bracket, drill to accept cable clamps . make holes and thread bracket holes ,mounted on helm and check allignment of cable on helm , make shim to correct allignment ,install and check idle position to wot on engine throttle lever . to short of throw on engine but if you release off lever ball the cable had enought throw so had to make new set off holes on engine bracket. reinstall -----------------perfect idle to wot.

sim angle bracket did not work .

sim angle bracket did not work .

capt.bob lico

bero13010473

bero13010473

Bob, that company should have provided you a field fix in my opinion

with a different plate, knowing it's not just you having this problem.

Maybe if everybody else would give them a call, they would? Or you can start your own "door to door" Solo mod service! From what I've gathered,

they don't have any tech support- maybe they should. That's frustrating to think of, such an otherwise good quality company that would stand behind there product.

with a different plate, knowing it's not just you having this problem.

Maybe if everybody else would give them a call, they would? Or you can start your own "door to door" Solo mod service! From what I've gathered,

they don't have any tech support- maybe they should. That's frustrating to think of, such an otherwise good quality company that would stand behind there product.

you know rocky i guess you might say differant strokes for differant folks . i am so use to "doing my own thing" from childhood i just take it in stride. i am not mad at solo i only made a small effort at contacting them and that was unproductive .every once in a while i am stumped especially with computers where there is no common sense for a solution. only as of late for the first time in my life i threw up my hands i had to bring the new mercedes to the dealer because i could not figure out how to get rid of that "change oil light" on computer dashboard.they will not allow you to change your own oil on a mercedes clk.the technician (not mechanic anymore) say don`t even think about changing brakes you need a laptop with program to set up brakes afterwards. oh great!!!

capt.bob lico

bero13010473

bero13010473

-

Whaler1777

- Senior Member

- Posts: 649

- Joined: Sep 10th, '06, 19:43

- Location: NY

Rocky, I'm going to play devils advocate here.

It's pretty difficult to field fix a problem when you do not know exactly where the problem lies.

Someone calling and saying they do not have enough throw...does not tell much. Just whipping out a new Cam with additional motion is not the first step. First you need to isolate the problem.

When pictures where provided they saw a setup that was not considered a Stock Setup. The first steps offered by the Solo Tech was to get the unit setup in a stock manner and take it from there.

Bob found a great solution that worked for him before we got to that Stock setup and verified all the measurements.

The Solo company knows this customer had a problem, the company knows how he fixed the problem. The company still does not know exactly why the problem was encountered. They offered to help, they offered to fix if a fix was needed True that was after the fact, but they put it out there, so if anyone else needs a fix...

It's pretty difficult to field fix a problem when you do not know exactly where the problem lies.

Someone calling and saying they do not have enough throw...does not tell much. Just whipping out a new Cam with additional motion is not the first step. First you need to isolate the problem.

When pictures where provided they saw a setup that was not considered a Stock Setup. The first steps offered by the Solo Tech was to get the unit setup in a stock manner and take it from there.

Bob found a great solution that worked for him before we got to that Stock setup and verified all the measurements.

The Solo company knows this customer had a problem, the company knows how he fixed the problem. The company still does not know exactly why the problem was encountered. They offered to help, they offered to fix if a fix was needed True that was after the fact, but they put it out there, so if anyone else needs a fix...

Bob,

I understand there is a problem, or in your case "was" a problem. Now exactly where that problem is we really do not know. You may have hit the nail on the head with your remedy, as the Cams may indeed have been cut short from day one. Maybe the Cam follower is "off". It is also possible RG Rollins published lousy Manuals and have their customers hooking these things up incorrectly.

RG seemed helpful, they went out of there way standing behind the product. If someone is not handy with a Dremel / Die Grinder it may be in there best interest to give them a call.

I understand there is a problem, or in your case "was" a problem. Now exactly where that problem is we really do not know. You may have hit the nail on the head with your remedy, as the Cams may indeed have been cut short from day one. Maybe the Cam follower is "off". It is also possible RG Rollins published lousy Manuals and have their customers hooking these things up incorrectly.

RG seemed helpful, they went out of there way standing behind the product. If someone is not handy with a Dremel / Die Grinder it may be in there best interest to give them a call.

Hi guys, so Carl and Bob, I guess what I was trying to say is this problem you had Bob, seems to be the same as more than a few others problem as well, coming from the control. Only trying to see if every one else can

benefit from all the work yous guys put into rectifying the problem thats all. A manual saying the total throw is only 1 3/4" and your guy you talked to at Solo Carl saying it has 2 1/4" is just not right! "Stock" setup or not, if the control only moves the cable 1 3/4", it is not according to there performance spec... I would love to hear everyone else that has this problem can get 2 1/4" total cable movement at the other end of there cable, then they would know it is not the control, just ratio problem.

benefit from all the work yous guys put into rectifying the problem thats all. A manual saying the total throw is only 1 3/4" and your guy you talked to at Solo Carl saying it has 2 1/4" is just not right! "Stock" setup or not, if the control only moves the cable 1 3/4", it is not according to there performance spec... I would love to hear everyone else that has this problem can get 2 1/4" total cable movement at the other end of there cable, then they would know it is not the control, just ratio problem.

Rocky- RG Rollins, the producers of the Solo II control say their product has a 2-1/2" throw, anything less is not right. They where standing behind that statement.

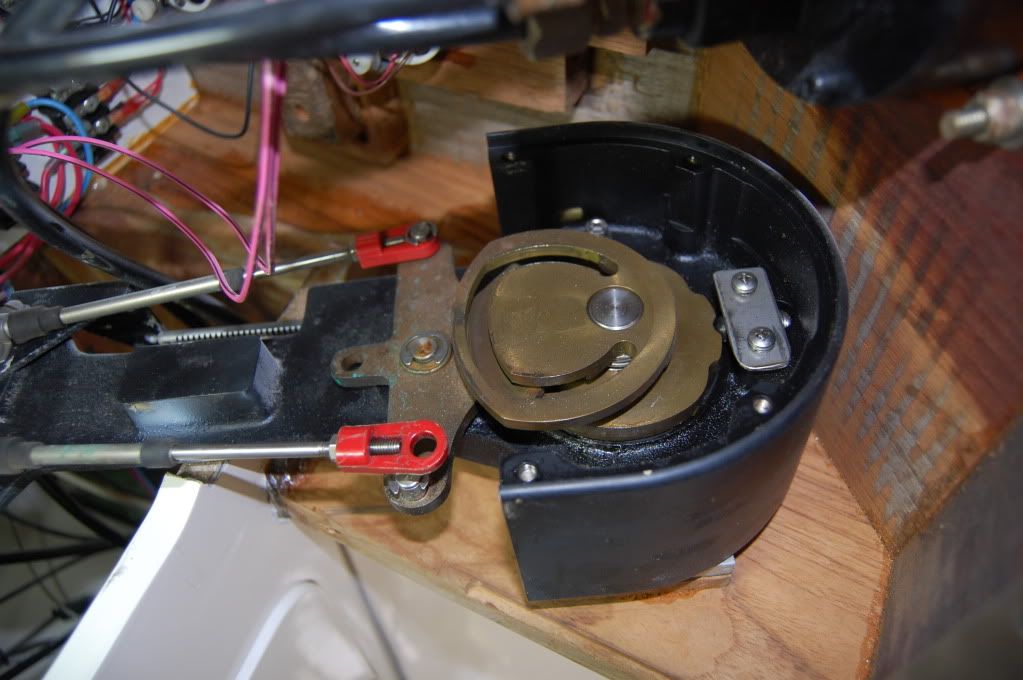

Possible reasons offered by RG that some will not get enough throw is the way the Cable Terminal Clips are installed. Those Red pieces shown in Bobs pictures. If they are not oriented properly they can hit the cover and stop travel.

Bob said this was not his issue as the clips where setup as per instructions and did not touch the cover. RG said the way they where setup they would hit the cover. I'm thinking Bob knows whether the clips are hitting the cover or not.

RG also mentioned the Throttle Cable Extension Bracket (The Black Angle Bracket being used as a shim under the Shift cable in the picture) was not in the Stock Position and would limit travel. Bob said that bracket did not work and made his own.

From where I sit, it sounds like RG makes a great product (people are buying' em and continue to use even with throw issues), but are providing less then adequate installation manuals. It may indeed be more then that...but at the very least I have to say the few pages I have seen lack detail and are open to interpretation.

Either way, RG says the throw is supposed to by 2-1/2". If you are not getting that RG will walk you thru the possible reasons and if that still does not get you to 2-1/2" of throw, they will take it back and repair.

If your more into the "Hands On, I want it done now method", Bob has that fix down.

Bob, I called RG and told them I was trying to help a customer/friend of mine with a problem. I was not their customer nor was I going to be, yet I was provided with a good deal of assistance and concern with rectifying the problem. I can't just turn my back on them in return.

...and you only know how good your friends are when the chips are down.

Possible reasons offered by RG that some will not get enough throw is the way the Cable Terminal Clips are installed. Those Red pieces shown in Bobs pictures. If they are not oriented properly they can hit the cover and stop travel.

Bob said this was not his issue as the clips where setup as per instructions and did not touch the cover. RG said the way they where setup they would hit the cover. I'm thinking Bob knows whether the clips are hitting the cover or not.

RG also mentioned the Throttle Cable Extension Bracket (The Black Angle Bracket being used as a shim under the Shift cable in the picture) was not in the Stock Position and would limit travel. Bob said that bracket did not work and made his own.

From where I sit, it sounds like RG makes a great product (people are buying' em and continue to use even with throw issues), but are providing less then adequate installation manuals. It may indeed be more then that...but at the very least I have to say the few pages I have seen lack detail and are open to interpretation.

Either way, RG says the throw is supposed to by 2-1/2". If you are not getting that RG will walk you thru the possible reasons and if that still does not get you to 2-1/2" of throw, they will take it back and repair.

If your more into the "Hands On, I want it done now method", Bob has that fix down.

Bob, I called RG and told them I was trying to help a customer/friend of mine with a problem. I was not their customer nor was I going to be, yet I was provided with a good deal of assistance and concern with rectifying the problem. I can't just turn my back on them in return.

...and you only know how good your friends are when the chips are down.

And as I said before, way to go Bob and Carl on fixing it. Also though,

Bob basically proved there was nothing wrong outside of HIS control that would inhibit the full travel stated, even making sure nothing was hitting the cover. All this is great information and maybe the rest will then want to

make sure there "setup" is according to RG, then go from there. It now sounds like RG Rollins is taking a sincere and thorough look into this problem I'm sure it's appreciated by all. Sorry for any "jumping to conclusions" on the technical dept. of the company, as I was only seing the result of you two talking to them.

Bob basically proved there was nothing wrong outside of HIS control that would inhibit the full travel stated, even making sure nothing was hitting the cover. All this is great information and maybe the rest will then want to

make sure there "setup" is according to RG, then go from there. It now sounds like RG Rollins is taking a sincere and thorough look into this problem I'm sure it's appreciated by all. Sorry for any "jumping to conclusions" on the technical dept. of the company, as I was only seing the result of you two talking to them.

sim one other questionable information supplied by solo. in regards to the timing issue of rack and gear what position of handle do we take that

.135 measurement from? i suspect neutral but nothing is said and what if measurement is off? go back to helm diagram for .135 illustration and tell me your and rocky tell me want you think.

.135 measurement from? i suspect neutral but nothing is said and what if measurement is off? go back to helm diagram for .135 illustration and tell me your and rocky tell me want you think.

capt.bob lico

bero13010473

bero13010473

Bob-

I'd only be taking a guess as my only information on these units comes from you, RG and the few pages you scanned. I never got to that point with RG...other then mentioning it to offer possible reasons the throw may be out.

From the limited information... I would guess you are correct. With the Handle at the Neutral indent the racks should protrude evenly from each side. That way the shifting would take place at the lowest idle. (center position of the cam)

If the racks are not even at the Handles Neutral indent I suspect you need to remove the secondary gear and manually position the racks evenly (at .135), then replace the gear.

I'm thinking if the Rack is not centered at Neutral, you'll wind up shifting when the engine is not at lowest idle when coming from one direction.

Is this what you have? or are they off a bit? If you need more... give me a shout or RG.

Carl

I'd only be taking a guess as my only information on these units comes from you, RG and the few pages you scanned. I never got to that point with RG...other then mentioning it to offer possible reasons the throw may be out.

From the limited information... I would guess you are correct. With the Handle at the Neutral indent the racks should protrude evenly from each side. That way the shifting would take place at the lowest idle. (center position of the cam)

If the racks are not even at the Handles Neutral indent I suspect you need to remove the secondary gear and manually position the racks evenly (at .135), then replace the gear.

I'm thinking if the Rack is not centered at Neutral, you'll wind up shifting when the engine is not at lowest idle when coming from one direction.

Is this what you have? or are they off a bit? If you need more... give me a shout or RG.

Carl

Bob, it would only be guessing what position to set the rack and gear to .135 at without someone coaching you through who built it.Hint Hint!

The logical thought would be nuetral detent, but without a written detail of EXACTLY how it's done, what if the rack is set wrong? If the info you showed us is the only setup info you have, it's not enough to go by...

mrsapiane@gmail.com I'll take a close look at all the insructions if you'd like me to.

The logical thought would be nuetral detent, but without a written detail of EXACTLY how it's done, what if the rack is set wrong? If the info you showed us is the only setup info you have, it's not enough to go by...

mrsapiane@gmail.com I'll take a close look at all the insructions if you'd like me to.

Wow Bob, that leaves a lot of variables on function worth another phone call maybe to have RG walk you through while it is in your hand so you can get a better understanding of setup procedure? Again, those instructions would leave me not sure it was timed correctly. I will call if you'd like, I'm off work tomorrow.

Who is online

Users browsing this forum: No registered users and 3 guests