Need diesel advise

Moderators: CaptPatrick, mike ohlstein, Bruce

Need diesel advise

I have Yanmar 240 HP 4LHA-STP's in my 31 and I think I have a fuel problem. The engines run fine at lower RPM's, but when I run them up above 2500 the RPM's will drop back to 2000 for a few seconds then back up to 2500. This happens alternately on both port and starboard engines. The boat sat with very little use for about 3 years before I bought her. I know the fuel is quite dirty because when I change the 10 micron racors, they are caked with material and when I shake them out over the bucket lots of sandy looking material comes out. I have gone through about 100 gallons of fuel since I bought the boat have 60 gallons in the tank right now.

I was wondering what the diesel experts on the site think I should do to fix my fuel problem. Initially I was thinking I would keep running fresh fuel through the engines and keep changing the racors until I cleaned the gunk out of the tank. This method does not seem to be working. Another option is to have a local marine yard suck the fuel out of the tank and filter it before putting it back in the boat. They said they probably could not get all of the junk in the tank due to the baffles. This would cost around $400. Is there another way to "open" the tank up to clean it. My deck has an access panel over the tank and there appears to be an inspection plate, but it does not look like it would be easy to get off. Also wondering weather I should be using 10 or 30 micron racors to deal with this. Thanks for any opinions and/or advise.

JR

I was wondering what the diesel experts on the site think I should do to fix my fuel problem. Initially I was thinking I would keep running fresh fuel through the engines and keep changing the racors until I cleaned the gunk out of the tank. This method does not seem to be working. Another option is to have a local marine yard suck the fuel out of the tank and filter it before putting it back in the boat. They said they probably could not get all of the junk in the tank due to the baffles. This would cost around $400. Is there another way to "open" the tank up to clean it. My deck has an access panel over the tank and there appears to be an inspection plate, but it does not look like it would be easy to get off. Also wondering weather I should be using 10 or 30 micron racors to deal with this. Thanks for any opinions and/or advise.

JR

- mike ohlstein

- Site Admin

- Posts: 2396

- Joined: Jun 29th, '06, 11:39

- Location: So many things seem like no-brainers until you run into someone with no brain.

- Contact:

Mike,

I've changed the racors about 4 time since I bought the boat and only changed the engine fuel filter once. I am going to pick up 2 engine fuel filters today and change those. I searched the old bulletin board and it seems that it's possible to take the inspection plate off of the top of the tank and clean and drain the tank. Uncle Vic uses gum out and a small copper tube hooked to a compressor to loosen the contents of the tank up after draining it. Any other suggestions on filters or tank cleaning?

JR

I've changed the racors about 4 time since I bought the boat and only changed the engine fuel filter once. I am going to pick up 2 engine fuel filters today and change those. I searched the old bulletin board and it seems that it's possible to take the inspection plate off of the top of the tank and clean and drain the tank. Uncle Vic uses gum out and a small copper tube hooked to a compressor to loosen the contents of the tank up after draining it. Any other suggestions on filters or tank cleaning?

JR

My dad made up a portable fuel polishing system. Basically a transfer pump plumbed to a pressure guage then to the filter/water seperator and a return line.

Now he cycles the fuel a few times thru this arrangement to clean the fuel of particles and water before putting in the tank. He has a couple 30gal barrels here for that purpose.

He made it up a couple years ago when he had an algea/dirt/debris problem, at that time he set it up to pull fuel from the very bottom of the tank with a long copper wand as a pickup tube. When he was down at the boat he would just let it run and run till it cloggged, changed the filter and let it do its thing. Finally he got to a point where the filters where not taking anything out and he was good to go.

Now he cycles the fuel a few times thru this arrangement to clean the fuel of particles and water before putting in the tank. He has a couple 30gal barrels here for that purpose.

He made it up a couple years ago when he had an algea/dirt/debris problem, at that time he set it up to pull fuel from the very bottom of the tank with a long copper wand as a pickup tube. When he was down at the boat he would just let it run and run till it cloggged, changed the filter and let it do its thing. Finally he got to a point where the filters where not taking anything out and he was good to go.

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

JR,

Your first stage Racors should be 30 micron and the engine mount filters 10 microns...

Your assumption that using the engines and Racors to eventually clean the tank is correct, but it would take forever. A commercial fuel polishing system consists of a high volume/pressure pump coupled to two huge Racor style filters and can move as much as 700 gallons of fuel an hour.

You should only have about 100 gallons on board for the polishing process. That would give you up to 7 turnovers in an hour. The fuel would be pumped through the pickup manifold and returned through the fill manifold plate. It would be best to remove the bolts from the plates and lift them up enough to get the suction and return hoses directly into the tank. The return hose is usually connected to a small diameter pipe and used as a wand to really stir the fuel around. The smaller diameter pipe is the key to getting a good circulating pressure.

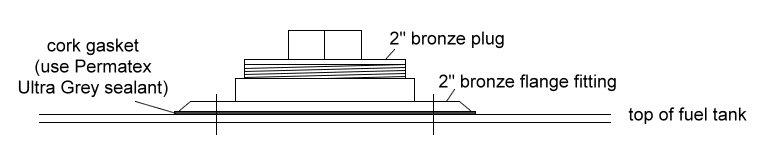

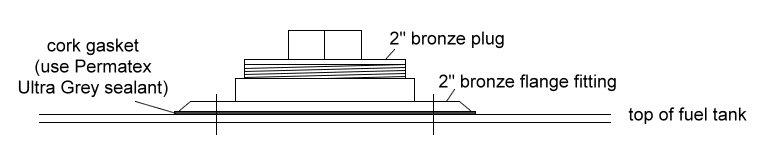

An alternate to unbolting the manifold plates is to permanantly install two flange and plug fittings on top of the tank. This would also make access easy when and if you need to re-polish the fuel again in the future. Don't worry about getting fiberglass dust into the tank, it'll get polished out...

Even with baffles, it's possible to get the fuel polished to a very high degree.

The choice is $400 per hour for one hour with the polishing system or $1 an hour for 400 hours using the engines to do the work...

Your first stage Racors should be 30 micron and the engine mount filters 10 microns...

Your assumption that using the engines and Racors to eventually clean the tank is correct, but it would take forever. A commercial fuel polishing system consists of a high volume/pressure pump coupled to two huge Racor style filters and can move as much as 700 gallons of fuel an hour.

You should only have about 100 gallons on board for the polishing process. That would give you up to 7 turnovers in an hour. The fuel would be pumped through the pickup manifold and returned through the fill manifold plate. It would be best to remove the bolts from the plates and lift them up enough to get the suction and return hoses directly into the tank. The return hose is usually connected to a small diameter pipe and used as a wand to really stir the fuel around. The smaller diameter pipe is the key to getting a good circulating pressure.

An alternate to unbolting the manifold plates is to permanantly install two flange and plug fittings on top of the tank. This would also make access easy when and if you need to re-polish the fuel again in the future. Don't worry about getting fiberglass dust into the tank, it'll get polished out...

Even with baffles, it's possible to get the fuel polished to a very high degree.

The choice is $400 per hour for one hour with the polishing system or $1 an hour for 400 hours using the engines to do the work...

- mike ohlstein

- Site Admin

- Posts: 2396

- Joined: Jun 29th, '06, 11:39

- Location: So many things seem like no-brainers until you run into someone with no brain.

- Contact:

Thanks for the reply's on my fuel problem. Sim, my brother and I have discussed coming up with a homemade polishing system like your dads. Sounds like a great way to keep the tank clean while saving on the yard charges.

Capt. Pat, thanks for the suggestion on the 30 micron racors. I have been using 10 micron racors, but I think they clog too fast. I think I will also implement your flange and plug fitting idea. It will be nice to have easy access to the tank. I think for now I'm going to take your advise and go with the $400 for one hour of professional polishing so I don't have to change racors in a pitching sea (as often).

Mike, I considered the collapsing possibility as well, but the boat runs great after I change the filters, so I'm going to check the hoses, but focus on cleaning the tank first.

Garry, thanks for the advise on cleaning the screens on the fuel intake tubes. How did you guy's do in the Cajun Canyon Tournament? I heard the tally was 18 Blue Marlin, 12 Swordfish and 2 White Marlin. I also heard that a 50 lb. dolphin was not even big enough for 3rd place. I hope to get this fuel issue under control so I can bring the boat down to Venice this summer. I'm probably going to take a couple of shake down cruises to the north shore before I run an offshore trip.

Thanks guy's for all of the great advise.

JR

Capt. Pat, thanks for the suggestion on the 30 micron racors. I have been using 10 micron racors, but I think they clog too fast. I think I will also implement your flange and plug fitting idea. It will be nice to have easy access to the tank. I think for now I'm going to take your advise and go with the $400 for one hour of professional polishing so I don't have to change racors in a pitching sea (as often).

Mike, I considered the collapsing possibility as well, but the boat runs great after I change the filters, so I'm going to check the hoses, but focus on cleaning the tank first.

Garry, thanks for the advise on cleaning the screens on the fuel intake tubes. How did you guy's do in the Cajun Canyon Tournament? I heard the tally was 18 Blue Marlin, 12 Swordfish and 2 White Marlin. I also heard that a 50 lb. dolphin was not even big enough for 3rd place. I hope to get this fuel issue under control so I can bring the boat down to Venice this summer. I'm probably going to take a couple of shake down cruises to the north shore before I run an offshore trip.

Thanks guy's for all of the great advise.

JR

I've orderd from these folks before, good prices and good service.

http://www.marinefilters.com/

br,

JohnD

http://www.marinefilters.com/

br,

JohnD

Jack,jackryan wrote:Thanks for the reply's on my fuel problem. Sim, my brother and I have discussed coming up with a homemade polishing system like your dads. Sounds like a great way to keep the tank clean while saving on the yard charges.

Capt. Pat, thanks for the suggestion on the 30 micron racors. I have been using 10 micron racors, but I think they clog too fast. I think I will also implement your flange and plug fitting idea. It will be nice to have easy access to the tank. I think for now I'm going to take your advise and go with the $400 for one hour of professional polishing so I don't have to change racors in a pitching sea (as often).

Mike, I considered the collapsing possibility as well, but the boat runs great after I change the filters, so I'm going to check the hoses, but focus on cleaning the tank first.

Garry, thanks for the advise on cleaning the screens on the fuel intake tubes. How did you guy's do in the Cajun Canyon Tournament? I heard the tally was 18 Blue Marlin, 12 Swordfish and 2 White Marlin. I also heard that a 50 lb. dolphin was not even big enough for 3rd place. I hope to get this fuel issue under control so I can bring the boat down to Venice this summer. I'm probably going to take a couple of shake down cruises to the north shore before I run an offshore trip.

Thanks guy's for all of the great advise.

JR

I had very similar symptoms 10 years ago with my dump truck motors...6v53n Only at high cruise or WOT throttle would she lose power. Changed filters, lines all, swapped pumps....nothing!!

The fuel was clean too, however. It turned out that the pick up(suction) hose had an air leak in it. replaced the hose and problem was solved.

Does the engine that loses power take a few more cranks to start than the one that does not?? That is a clue to a leak in the suction line.

Thanks Capy,

I changed the racors and secondary fuel filters again and took her for a spin today. They ran great at all RPM's. I was getting 35 mph at full throttle with no surging. The 4LHA-STP's have a small manual priming pump on the starboard side of the engine. I found both of these in the unscrewed "priming" position. Not sure if this had something to do with my surging problem, but it may have. We'll see shat happens as the filters get dirty again.

JR

I changed the racors and secondary fuel filters again and took her for a spin today. They ran great at all RPM's. I was getting 35 mph at full throttle with no surging. The 4LHA-STP's have a small manual priming pump on the starboard side of the engine. I found both of these in the unscrewed "priming" position. Not sure if this had something to do with my surging problem, but it may have. We'll see shat happens as the filters get dirty again.

JR

Who is online

Users browsing this forum: Google [Bot] and 2 guests