Brass, SS or Bronze fittings

Moderators: CaptPatrick, mike ohlstein, Bruce

Brass, SS or Bronze fittings

My buddy is installing Crash pumps-

I used to be able to get all Bronze fittings but now it seems I can no longer locate Bronze Nipples. 1-1/4" Nipple short as possible to connect the Seacock to the T, both have female ends.

I can get 316SS and Brass.

My marine wholesalers tell me the Bronze nipples came from China and where crap so they are discontinued and now they supply OEM, boat builders with Brass for those applications. It's always been my opinion not to use brass fittings with seawater below the waterline and I do not like the idea of mixing materails.

What is the right choice?

I used to be able to get all Bronze fittings but now it seems I can no longer locate Bronze Nipples. 1-1/4" Nipple short as possible to connect the Seacock to the T, both have female ends.

I can get 316SS and Brass.

My marine wholesalers tell me the Bronze nipples came from China and where crap so they are discontinued and now they supply OEM, boat builders with Brass for those applications. It's always been my opinion not to use brass fittings with seawater below the waterline and I do not like the idea of mixing materails.

What is the right choice?

- In Memory of Vicroy

- Senior Member

- Posts: 2340

- Joined: Jun 29th, '06, 09:19

- Location: Baton Rouge, LA

Thanks,

I forgot about plumbing supply houses. I will direct him in that direction, or just make the dam things.

Seems strange that 3 marine supply houses do not carry Bronze Nipples. Every other fitting and valve yes but only Brass and 304 SS Nipples and pipe...I don't get it.

Anyway thanks again,

Carl

I forgot about plumbing supply houses. I will direct him in that direction, or just make the dam things.

Seems strange that 3 marine supply houses do not carry Bronze Nipples. Every other fitting and valve yes but only Brass and 304 SS Nipples and pipe...I don't get it.

Anyway thanks again,

Carl

- In Memory Walter K

- Senior Member

- Posts: 2912

- Joined: Jun 30th, '06, 21:25

- Location: East Hampton LI, NY

- Contact:

- mike ohlstein

- Site Admin

- Posts: 2394

- Joined: Jun 29th, '06, 11:39

- Location: So many things seem like no-brainers until you run into someone with no brain.

- Contact:

Buy some bronze pipe and have your plumber thread it for you.

http://www.mcmaster.com/#bronze/=1r0epw

http://www.mcmaster.com/#bronze/=1r0epw

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

Here's the deal as I know it:

First, the key issue, from the point of electrolytic corrosion, is the content of zinc in the brass alloy.

High zinc content, (30% - 40%) brass is called yellow brass. In a marine environment, passing raw water through yellow brass will cause the zinc in the alloy to be dissolved rather quickly. (days to weeks to maybe even a month or so.)

Low zinc content, (5% - 15%) brass is called red brass. In the same marine environment, passing raw water through red brass will still cause some very slow acting dissolving of the zinc, but the process will be slowed to a crawl over many years. Especially when properly bonded.

Second, the key manufacturing issue in producing seamless pipe is the way it is manufactured. It's done by casting a billet of metal, shaping it to a solid base round stock and compressing it through die rollers and piercing to get the hollow pipe. Basically an extrusion process. Zinc is a necessary component for this forming process when extruding copper alloys.

Bronze, (there are numerous alloys), have very little zinc content and therefore are rather impervious to the galvanic action of moving raw water. Bronze is readily cast and fairly easy to thread, but is not able to be easily formed into seamless pipe through the extrusion process.

The alloy of "bronze" used mostly in the marine industry is called Naval or Admiralty Brass, which contains tin in place of zinc. Again, very difficult form into seamless pipe.

Years ago, red brass was simply sold as "bronze" pipe. Red brass has been used in conjunction with bronze castings for over a hundred years.

So the bottom line, again as I understand it, Red brass is more than acceptable for carrying raw water in a marine environment and NO seamless extruded pipe will be "bronze". A "bronze" pipe would have to be cast as pipe, causing it to have a very heavy wall thickness to allow the threading. Also, any length of the pipe would have to relative short in relation to is diameter and wall thickness. Just not industrially economical...

Yellow brass in a raw water system is the kiss of death...

The only other way around eliminating brass of any kind would be to use stainless steel and issolate any dissimilar metals with TefGel.

Br,

Patrick

First, the key issue, from the point of electrolytic corrosion, is the content of zinc in the brass alloy.

High zinc content, (30% - 40%) brass is called yellow brass. In a marine environment, passing raw water through yellow brass will cause the zinc in the alloy to be dissolved rather quickly. (days to weeks to maybe even a month or so.)

Low zinc content, (5% - 15%) brass is called red brass. In the same marine environment, passing raw water through red brass will still cause some very slow acting dissolving of the zinc, but the process will be slowed to a crawl over many years. Especially when properly bonded.

Second, the key manufacturing issue in producing seamless pipe is the way it is manufactured. It's done by casting a billet of metal, shaping it to a solid base round stock and compressing it through die rollers and piercing to get the hollow pipe. Basically an extrusion process. Zinc is a necessary component for this forming process when extruding copper alloys.

Bronze, (there are numerous alloys), have very little zinc content and therefore are rather impervious to the galvanic action of moving raw water. Bronze is readily cast and fairly easy to thread, but is not able to be easily formed into seamless pipe through the extrusion process.

The alloy of "bronze" used mostly in the marine industry is called Naval or Admiralty Brass, which contains tin in place of zinc. Again, very difficult form into seamless pipe.

Years ago, red brass was simply sold as "bronze" pipe. Red brass has been used in conjunction with bronze castings for over a hundred years.

So the bottom line, again as I understand it, Red brass is more than acceptable for carrying raw water in a marine environment and NO seamless extruded pipe will be "bronze". A "bronze" pipe would have to be cast as pipe, causing it to have a very heavy wall thickness to allow the threading. Also, any length of the pipe would have to relative short in relation to is diameter and wall thickness. Just not industrially economical...

Yellow brass in a raw water system is the kiss of death...

The only other way around eliminating brass of any kind would be to use stainless steel and issolate any dissimilar metals with TefGel.

Br,

Patrick

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

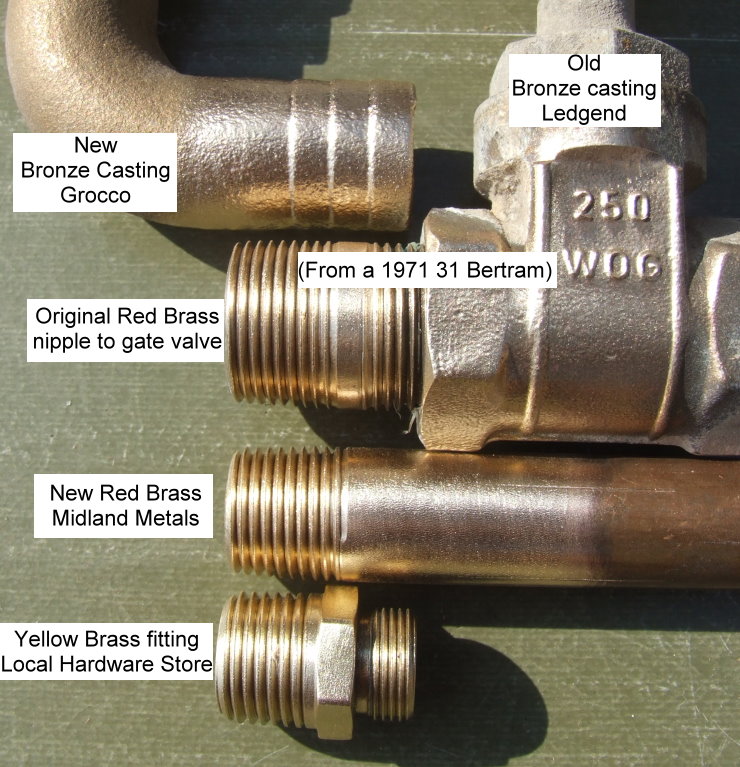

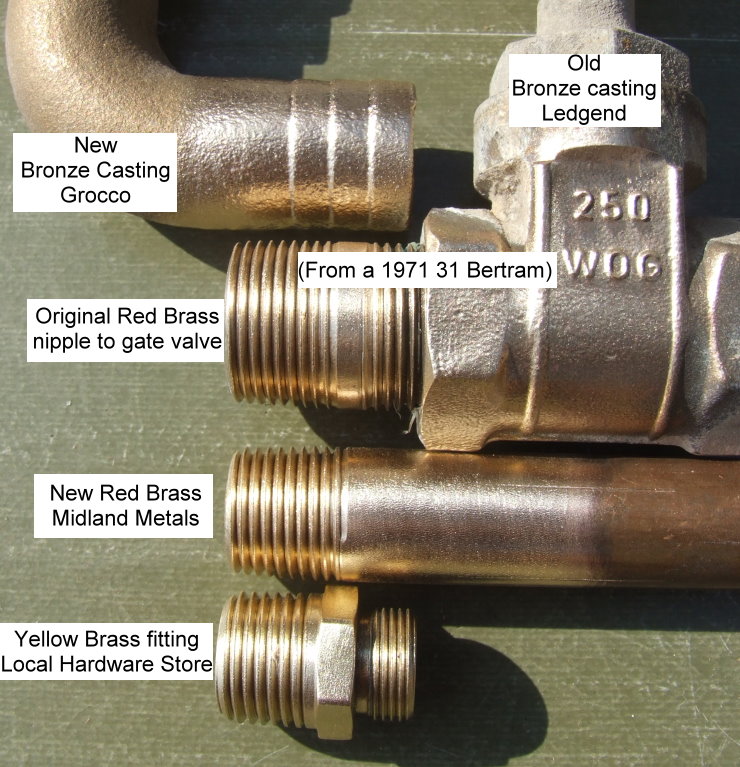

Just as a visual point of comparrison, here's 5 items, 2 of which are "bronze", 2 are Red Brass, and 1 is Yellow Brass.

When cleaned up on a wire wheel, the red brass and bronze have an almost identical pinkish tone to the color. The yellow brass is distinctively more yellow. (Harder to see in an Internet image, but far more evident in real life...)

The color difference between red brass and yellow brass is from the difference of copper content. The higher the copper content, the more the red tone is noticed, and vise versa for yellow brass.

In the case of the red brass nipple associated with the Ledgend brand bronze gate valve, there is absolutely no sign of corrosion on the inside of the nipple. This was original Bertram installation that saw at least 35 years of service before I removed it for up-sizing and changing from the gate valve to ball valve.

When cleaned up on a wire wheel, the red brass and bronze have an almost identical pinkish tone to the color. The yellow brass is distinctively more yellow. (Harder to see in an Internet image, but far more evident in real life...)

The color difference between red brass and yellow brass is from the difference of copper content. The higher the copper content, the more the red tone is noticed, and vise versa for yellow brass.

In the case of the red brass nipple associated with the Ledgend brand bronze gate valve, there is absolutely no sign of corrosion on the inside of the nipple. This was original Bertram installation that saw at least 35 years of service before I removed it for up-sizing and changing from the gate valve to ball valve.

OK...i am completely confused (dont say it). i bought two 18" red brass (didnt know any better, mc-carr...said marine use) tubes to move my valves out from under the engine to where i could easily reach them. should i live with them for now . change them for bronze (not a real easy but certainly doable task) before i put the boat in or just forget about em. would putting zinks on them as if they were shafts be a dumb idea?

yikes!!

yikes!!

- mike ohlstein

- Site Admin

- Posts: 2394

- Joined: Jun 29th, '06, 11:39

- Location: So many things seem like no-brainers until you run into someone with no brain.

- Contact:

Capt Pat, thank you for clarifing the difference between Yellow Brass and Red Brass. I grouped them together not realizing there is a pretty big difference, just had it in my head not to use Brass because of the Zinc content.

Up till recently I used to be able to get Bronze Nipples from several sources, pricey as they where machined castings, but customers who asked for them didn't seem to care as long as it was Bronze.

For my friend I reccomeded the Bronze and told him why not to use Brass, then I had to tell him I couln't get Bronze. I gave him all the info offered to make from Bronze and let him choose. He went with the Red Brass, thanks.

Carl

Not seamless pipe but gets you close to net size http://anchormetals.com/continuouscast.htm

Up till recently I used to be able to get Bronze Nipples from several sources, pricey as they where machined castings, but customers who asked for them didn't seem to care as long as it was Bronze.

For my friend I reccomeded the Bronze and told him why not to use Brass, then I had to tell him I couln't get Bronze. I gave him all the info offered to make from Bronze and let him choose. He went with the Red Brass, thanks.

Carl

Not seamless pipe but gets you close to net size http://anchormetals.com/continuouscast.htm

-

Raybo Marine NY

- Senior Member

- Posts: 907

- Joined: Jan 3rd, '07, 00:28

- Location: Lindenhurst, NY

- Contact:

Who is online

Users browsing this forum: No registered users and 56 guests