generator placement

Moderators: CaptPatrick, mike ohlstein, Bruce

-

Bermuda Brother

- Senior Member

- Posts: 66

- Joined: Aug 17th, '06, 20:36

- Location: Bermuda

generator placement

Hi Guys!

Will be running probably a Cruisair 16000BTU and thus a generator to power it.

Was thinking about the small Panda 4kw unit and placing it in the space at the rear of the fuel tank in order to a). keep as much weight at the back of the boat as possible and b). have the noise as far away from cabin as possible. Not sure if it is really such a good idea. Will it really get wet from the bilge water? The unit is fully enclosed. Anyone tried this position?

Also what is the best choice of generator for my purposes in your opinion?

I was initially hoping to run the AC off an inverter without the noisy genset. I did this successfully with a smaller 5000btu unit which would run all night and not drain 5 D size gel batteries. I was thinking of installing a larger battery bank of the more compact Odyssey batteries and try to run the 16000btu off an inverter. I am beginning to think this unrealistic.

What does the sandbox say?

JJ

Will be running probably a Cruisair 16000BTU and thus a generator to power it.

Was thinking about the small Panda 4kw unit and placing it in the space at the rear of the fuel tank in order to a). keep as much weight at the back of the boat as possible and b). have the noise as far away from cabin as possible. Not sure if it is really such a good idea. Will it really get wet from the bilge water? The unit is fully enclosed. Anyone tried this position?

Also what is the best choice of generator for my purposes in your opinion?

I was initially hoping to run the AC off an inverter without the noisy genset. I did this successfully with a smaller 5000btu unit which would run all night and not drain 5 D size gel batteries. I was thinking of installing a larger battery bank of the more compact Odyssey batteries and try to run the 16000btu off an inverter. I am beginning to think this unrealistic.

What does the sandbox say?

JJ

A gen set is so much handier and lighter than 5 8D batteries but I would not place it behind the tank.

Wet location and access to the aft bilge pump would be a major concern.

Most place outside of port engine for balance of head and galley.

If its in a sound sheild, noise shouldn't be a problem. I've installed both Mase and Next Gen in this configuration with good success.

The mase being a 3600 rpm unit and the Next gen being a 1800 rpm unit.

You can also add insulation to the engine compartment.

Wet location and access to the aft bilge pump would be a major concern.

Most place outside of port engine for balance of head and galley.

If its in a sound sheild, noise shouldn't be a problem. I've installed both Mase and Next Gen in this configuration with good success.

The mase being a 3600 rpm unit and the Next gen being a 1800 rpm unit.

You can also add insulation to the engine compartment.

My install is identical to what Bruce describes.Bruce wrote:.

Most place outside of port engine for balance of head and galley.

If its in a sound sheild, noise shouldn't be a problem. I've installed both Mase and Next Gen in this configuration with good success.

The mase being a 3600 rpm unit and the Next gen being a 1800 rpm unit.

You can also add insulation to the engine compartment.

--JK

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

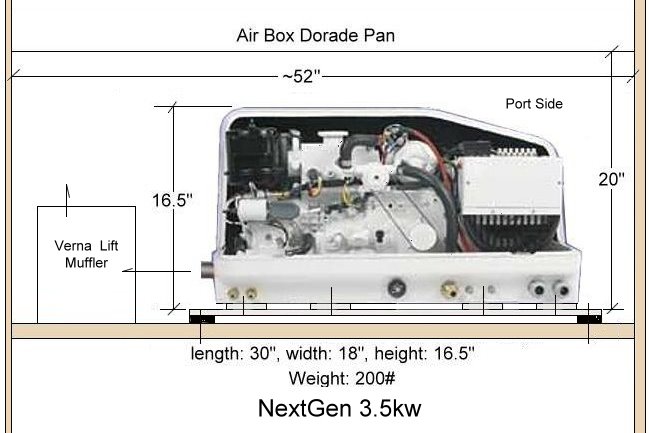

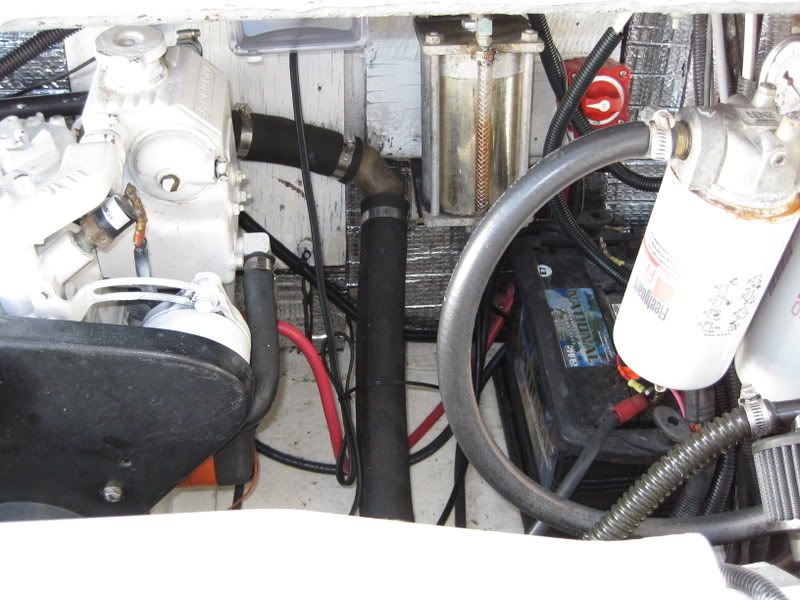

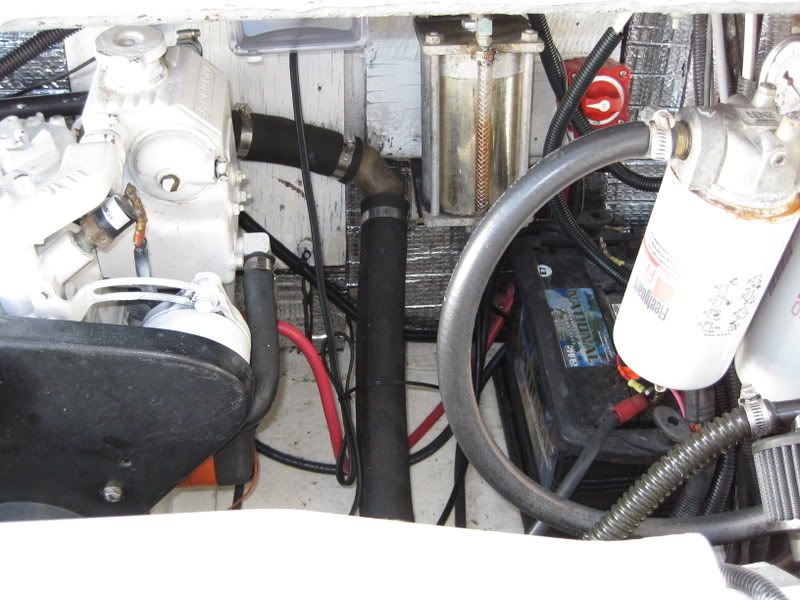

A brief generator image collection of Patrick Hancock's B31 in progress

The aft bilge would be the very last place I'd ever put a gen set on any boat. My first professional ride was a '46 Bertram: Lesson Learned.

The aft bilge would be the very last place I'd ever put a gen set on any boat. My first professional ride was a '46 Bertram: Lesson Learned.

-

Bermuda Brother

- Senior Member

- Posts: 66

- Joined: Aug 17th, '06, 20:36

- Location: Bermuda

hey pat,

Thanks for the image. What do you think of the mase versus the Panda or any other? Which would you go for? This one looks smaller than the panda. But how many kw and how many dB's, reliability?

Cute little unit though!

Is it possible to even run a 16000btu off an inverter? Maybe using inverter first with auto start gen as backup?

JJ

Thanks for the image. What do you think of the mase versus the Panda or any other? Which would you go for? This one looks smaller than the panda. But how many kw and how many dB's, reliability?

Cute little unit though!

Is it possible to even run a 16000btu off an inverter? Maybe using inverter first with auto start gen as backup?

JJ

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

JJ,

I can't advise you on the particulars, I'm neither a mechanic or an electrician, but if you want high capacity air conditioning, a generator is a necessity. Currently, I favor the 3.5kw Nextgen...

By the time you configure an inverter and battery system to tackle the demand of a 16,000btu a/c unit, you've spent about the same as the generator and, away from shore power, you can only recharge the batteries via the engine alternators. Not the system I'd want...

Boats are boats and noise on power boats just comes with the territory. Proper sound insulation can reduce the decibel level to a minimum. The only time that engine noise would be troublesome, at least to me, would an overnight sleep. I'd rather don a pair of Bose noise cancelers and sleep in cool air than sweat in silence.

Also, I'd never feel safe running high demand electrical equipment off of my main cranking batteries. Those batteries need to be dedicated to the engines and only shared with the bilge pumps. For an inverter system, a decent sized a/c unit, microwave, lighting, etc., your house battery bank would have to be huge.

Br,

Patrick

I can't advise you on the particulars, I'm neither a mechanic or an electrician, but if you want high capacity air conditioning, a generator is a necessity. Currently, I favor the 3.5kw Nextgen...

By the time you configure an inverter and battery system to tackle the demand of a 16,000btu a/c unit, you've spent about the same as the generator and, away from shore power, you can only recharge the batteries via the engine alternators. Not the system I'd want...

Boats are boats and noise on power boats just comes with the territory. Proper sound insulation can reduce the decibel level to a minimum. The only time that engine noise would be troublesome, at least to me, would an overnight sleep. I'd rather don a pair of Bose noise cancelers and sleep in cool air than sweat in silence.

Also, I'd never feel safe running high demand electrical equipment off of my main cranking batteries. Those batteries need to be dedicated to the engines and only shared with the bilge pumps. For an inverter system, a decent sized a/c unit, microwave, lighting, etc., your house battery bank would have to be huge.

Br,

Patrick

- In Memory of Vicroy

- Senior Member

- Posts: 2340

- Joined: Jun 29th, '06, 09:19

- Location: Baton Rouge, LA

JJ - When I became the Steward of AJ in the early 90s she had a 4.0 KW single cylinder Farrymann genset that ran at 3600 rpm and was like having a lawn mower in the bilge. It was mounted on the outboard side of the port 6BTA Cummins. It finally blew to bits from excessive vibration, etc. and I replaced it with a 5.5 KW three cylinder Kubota powered Phasor at 1800 RPM. No sound shield and very quiet and smooth. Katrina ate the 5.5 after thousands of hours and it was replaced in 2006 with a Phasor 6.5 KW that is esentially the same as the 5.5 but a little smaller and a lot stronger. Great little genset and would probably run TWO 16000 BTU a/c units with no sweat.

Go direct coupled (no belts) and 1800 rpm.

UV

Go direct coupled (no belts) and 1800 rpm.

UV

-

Bermuda Brother

- Senior Member

- Posts: 66

- Joined: Aug 17th, '06, 20:36

- Location: Bermuda

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

As Vic pointed out: It's a matter of weight distribution. But if you can divise a system that all of your locked down components, (engines, a/c, genset, batteries, charger, galley, etc), are as evenly counterbalanced as possible, to obtain a good port to starboard trim at rest and correct fore and aft trim when running, then there's no rule to say that a starboard installation is incorrect.

- In Memory Walter K

- Senior Member

- Posts: 2912

- Joined: Jun 30th, '06, 21:25

- Location: East Hampton LI, NY

- Contact:

JJ,

Check out which side service items are on the genset you want. Exhaust outlet, raw water intake, fuel and oil filters and fills along with fuel line access. Most are mounted on the port side because this allows the easiest access to filters and plumbing for lines.

The second thing you need to make sure is that once the generator is installed you have access to the engine components. A starboard mounted genset means interference with fuel and oil filter. A port side mounted genset means it has to be far enough back to allow access to change the water pump and impeller. UV's 250's are alot narrower than your 370's.

If you want to check the fit get a box the size of the gen set and put out board of each motor. Its an eye opening experience.

Check out which side service items are on the genset you want. Exhaust outlet, raw water intake, fuel and oil filters and fills along with fuel line access. Most are mounted on the port side because this allows the easiest access to filters and plumbing for lines.

The second thing you need to make sure is that once the generator is installed you have access to the engine components. A starboard mounted genset means interference with fuel and oil filter. A port side mounted genset means it has to be far enough back to allow access to change the water pump and impeller. UV's 250's are alot narrower than your 370's.

If you want to check the fit get a box the size of the gen set and put out board of each motor. Its an eye opening experience.

KR

JP

1977 RLDT "CHIMERA"

JP

1977 RLDT "CHIMERA"

jp the picture i posted above is my 330hp which is exactly the same as 370 except for recalibration of fuel injection pump.the only differance is my add ons like engine and gear oil removal,relocation of engine oil dipstick,and fiberglass tube in between water outlet from heat exchanger and sprinkler head on exhaust (has sensor to indicate loss of water flow) .

generater is mase 4.0 and exhaust goes thru muffler and then to water/ gas seperator to completely run silent for overnight canyon trips.generator has dedicated/ seperate fuel hoses thru racor 500,along with seperate battery source and can charge thru isolation blocks port/starboard/house batterys.

generater is mase 4.0 and exhaust goes thru muffler and then to water/ gas seperator to completely run silent for overnight canyon trips.generator has dedicated/ seperate fuel hoses thru racor 500,along with seperate battery source and can charge thru isolation blocks port/starboard/house batterys.

capt.bob lico

bero13010473

bero13010473

-

Bermuda Brother

- Senior Member

- Posts: 66

- Joined: Aug 17th, '06, 20:36

- Location: Bermuda

Ok some questions;

Do these generators have to be installed b4 the engines are? Can they be taken out and replaced once the engines are in place?

Will the 3.4 kw NextGen be ok to power a 16000 btu AC?

Is there any benefit to installing a larger more powerful genset if I only plan to run AC (how bout a small fridge as well?)

I notice that Vic has opted for a more powerful unit and I was wondering why he did?

JJ

Do these generators have to be installed b4 the engines are? Can they be taken out and replaced once the engines are in place?

Will the 3.4 kw NextGen be ok to power a 16000 btu AC?

Is there any benefit to installing a larger more powerful genset if I only plan to run AC (how bout a small fridge as well?)

I notice that Vic has opted for a more powerful unit and I was wondering why he did?

JJ

JJ,

Better to install before, just because it 's easier to fit everything together. But mind will come out without having to remove the engine also, also very easy to service outboard Port engine.

You might as well just go ahead an do the 5.5 NextGen and be done with worrying about whether or not the 3.5 is big enough. Because next you will want to add a microwave and other little goodies along with the frig. not that much difference in price and about the same in size. Mine is outboard of my 6bta/250hp and fits fine.

DQ

Better to install before, just because it 's easier to fit everything together. But mind will come out without having to remove the engine also, also very easy to service outboard Port engine.

You might as well just go ahead an do the 5.5 NextGen and be done with worrying about whether or not the 3.5 is big enough. Because next you will want to add a microwave and other little goodies along with the frig. not that much difference in price and about the same in size. Mine is outboard of my 6bta/250hp and fits fine.

DQ

1967 Hull #315-605 FBC ---<*)((((><(

"IN GOD WE TRUST"

'Life may be the party we hoped for...but while we are here we might as well fish'!

"IN GOD WE TRUST"

'Life may be the party we hoped for...but while we are here we might as well fish'!

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

The generator has to go in place before the engine. You'll never squeeze one in or out with the engine in place, but jerkin' an engine from a B31 is about only a one hour deal, and another 30 minutes to re-check the alignment...Do these generators have to be installed b4 the engines are? Can they be taken out and replaced once the engines are in place?

We installed a Mase 2.5kw in Buddy Boy, equipped with 12K btu a/c, microwave, & fridge. To the best of my knowledge, was never a problem. Hancock's B31 is getting the 3.5kw NextGen, equipped with a 16k btu a/c, microwave and fridge. I don't anticipate any problems there either.

The 3.5kw Nextgen dimensions are 28* long x 15" wide x 15" high at a dry weight of 160 lbs (w/ sound shield: length: 30"; width: 18"; height: 16.5")

The 5.5 Nextgen dimensions are 23" long x 17' wide x 20" high, and dry weight is 230 lbs. (w/ sound shield: length: 25.5"; width: 20"; height: 22")

(Source: http://nextgenerationpower.com/marinegen.html )

So if you think to go with the 5.5, plan carefully for extra 2" of width, extra 5" of height, & extra 70 lbs of weight. The length is to your advantage, but you've got 52" from bulkhead to bulkhead, so not any real advantage there.

There's no way a 5.5 Nextgen's dimensions would work on the the B31 I'm doing now. And that's with Yanmar 4LHs as opposed to Buddy Boy's 6LHs... There's no way more than 18 or so inches would fit under my side air box.

Br,

Patrick

-

Bermuda Brother

- Senior Member

- Posts: 66

- Joined: Aug 17th, '06, 20:36

- Location: Bermuda

thanks guys,

And Pat I have your air boxes too so I guess the 5.5 definitely won't fit.

Also Pat, was thinking of installing the battery bank aft of the fuel tank to get as much weight in the back as possible for the sake of the 370's. I accept that this is not a good location for a genset but I thought the Odyssey batteries might survive the environment with Corrosion X applied frequently to the terminals.

What are your thoughts?

JJ

And Pat I have your air boxes too so I guess the 5.5 definitely won't fit.

Also Pat, was thinking of installing the battery bank aft of the fuel tank to get as much weight in the back as possible for the sake of the 370's. I accept that this is not a good location for a genset but I thought the Odyssey batteries might survive the environment with Corrosion X applied frequently to the terminals.

What are your thoughts?

JJ

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

Wouldn't be my choice of locations... First, with a shelf high enough, large enough, and strong enough, you'll have a hellofa' time accessing the bilge and bilge pump. Second you're battery cables would be over 10' long so you'd have to, (to be safe), run 4/0 AWG cable for the cranking batteries and 2/0 AWG for the house battery(s). (see: http://www.alternatorparts.com/wire_size_chart.htm )was thinking of installing the battery bank aft of the fuel tank

The center bilge is where I mount them. That's the lowest, on center, at admidships, and best balanced area for the weight. Easy access, plenty of room, and best location from the standpoint of the moment of inertia, (countering side to side roll).

- In Memory Walter K

- Senior Member

- Posts: 2912

- Joined: Jun 30th, '06, 21:25

- Location: East Hampton LI, NY

- Contact:

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

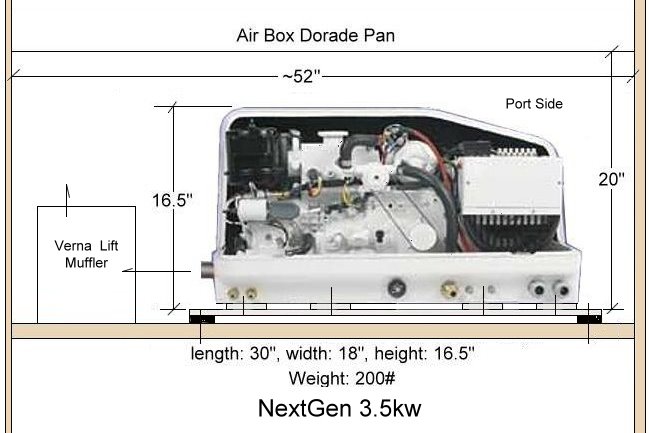

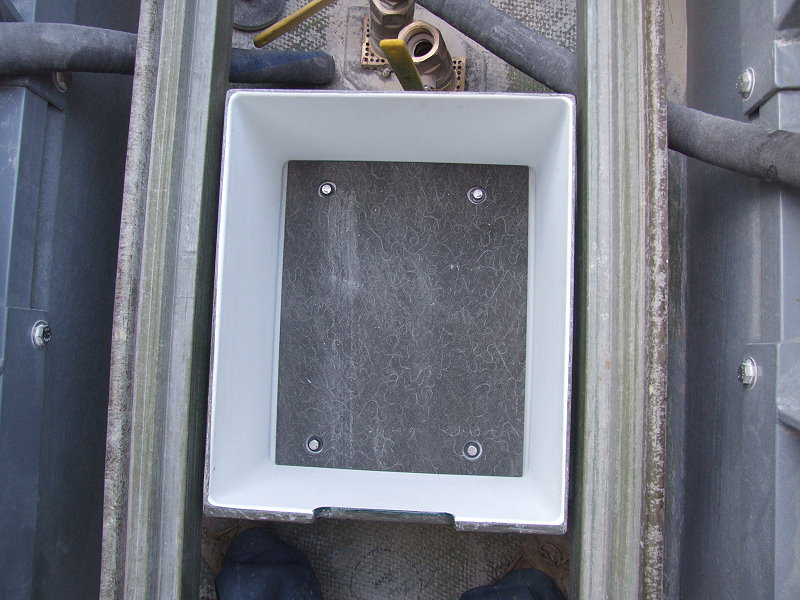

Rawleigh,Rawleigh wrote:Pat: What are all of the holes in the blocks under the thru hulls for? Adhesion?

Those are the pick up strainers for the crash pumps... Strictly inboard 1 1/2" valves, one per engine. They're fitted to a studed fiberglass plate which is bonded to the hull. Low profile, no scews...

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

Capt. Patrick, I actually think that mounting weight on the outside of the boat, as far away from the pivit point will slow the side to side roll. Having all the weight on center gives no resistance to movement, outboard weight must be raised (but also lowered) and should slow movement. I think all your weight on the center of pivot will promote a faster "snap" type on movement. I am not 100% on this though. It's kinda like the "FLOPPER STOPPERS", the longer the moment arm the more resistance to roll.The center bilge is where I mount them. That's the lowest, on center, at admidships, and best balanced area for the weight. Easy access, plenty of room, and best location from the standpoint of the moment of inertia, (countering side to side roll).

What do you guys think? Buy the way, I think between the engines is the best place for the batterys, but for easy access, not to counter roll.

ScottD

capt. patrick we have a very similar approach to raw water intake and crash valves ,what i don`t understand is how does the crash valve work after you close it to sea water the water is taken from the bilge you have the valve above intake grill??? i have a photo of mine there are two short hoses that hang off the crash valve intakes that hang in the bilge.unlike your version up north the crash valve is use to circulate antifreeze to the engines in winter layup.just takes a couple of minutes to see antifreeze flowing out exhaust.-------------put it away!

capt.bob lico

bero13010473

bero13010473

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

That would hold true if the center line weight was on the same plane level as an counter balanced outboard weight. But first, the outboard weight would have to be equally divided and thereby countering each other.ScottD wrote: Capt. Patrick, I actually think that mounting weight on the outside of the boat, as far away from the pivit point will slow the side to side roll. Having all the weight on center gives no resistance to movement, outboard weight must be raised (but also lowered) and should slow movement. I think all your weight on the center of pivot will promote a faster "snap" type on movement. I am not 100% on this though. It's kinda like the "FLOPPER STOPPERS", the longer the moment arm the more resistance to roll.

What do you guys think? Buy the way, I think between the engines is the best place for the batterys, but for easy access, not to counter roll.

ScottD

In this case, however, the centerline weight is lower than the outboard weight could be. Also, because the single weight on center will be twice as heavy as two opposing outboard weights, you've set up an imbalance by lowering the center of gravity, that not only favors the resting attitude of the boat, but also increases the amount of force needed to move the weight off of plumb.

By counter balancing weights outboard you need far more spred distance and overall weight to achieve the same results as an single centerline weight.

Naturally, we can't go very deep inside the hull of a power boat and don't want the external baggage of a true keel. But, centerline and amidships location of weight is exactly why sailboats are designed the way they are.

The deep keel and heavy lead ingot at the bottom help counter balance the height and forces of the boat above the water line. The higher the superstructure & masts become, & the more sail you put into the wind, the more weight is required and the deeper it needs to be. This holds true for both side to side and fore to aft balance. Gravity always wants that concentration of weight to be in a plumb attitude while afloat.

Remember, we're talking about a boat in water going back and forth, not a figure skater tucking his arms into his chest to get a faster rotation or extending them to slow down...

Br,

Patrick

Bob,

I think you're rule will pump more water than the crash valves.

Think about drinking a 20 oz cocktail through a stir straw vs. drinking it through a garden hose.

No matter how big the pump sucking on those little straws is it will only draw as much water as the little straw allows. Throw out the baby pipe and install the same diameter as the intake hose, then you'll have all protection available.

Looks good enough for winterizing though

I think you're rule will pump more water than the crash valves.

Think about drinking a 20 oz cocktail through a stir straw vs. drinking it through a garden hose.

No matter how big the pump sucking on those little straws is it will only draw as much water as the little straw allows. Throw out the baby pipe and install the same diameter as the intake hose, then you'll have all protection available.

Looks good enough for winterizing though

KR

JP

1977 RLDT "CHIMERA"

JP

1977 RLDT "CHIMERA"

those crash valves are 1" and so is the hose custon made (non kinking type) for the valves with the cummins water pump those babies can really pump i tested them.hope to god i never have to use them as crash valves.the man reason is to buy some time to get into life raft and being in the (100 mile square) i could radio someone in my proximity.i have 6 bilge pumps on 4 odassey batteries and isolation type main bulkhead like shown in capt patricks post.i sure you share the same fear as i do on a overnighter hitting a underwater ( or level with water) container drop off one of the many ships heading into ny harbor.

capt.bob lico

bero13010473

bero13010473

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

Bob,bob lico wrote:those crash valves are 1" and so is the hose custon made (non kinking type) for the valves with the cummins water pump those babies can really pump i tested them.hope to god i never have to use them as crash valves.the man reason is to buy some time to get into life raft and being in the (100 mile square) i could radio someone in my proximity.i have 6 bilge pumps on 4 odassey batteries and isolation type main bulkhead like shown in capt patricks post.i sure you share the same fear as i do on a overnighter hitting a underwater ( or level with water) container drop off one of the many ships heading into ny harbor.

Like JP said, fine for winterizing. But engine run crash pumps should be matched in hose size to that of the standard engine raw water fittings. The big deal there is that you do not want to starve the engines of cooling water, besides eliminating excess bilge water. Lot of volumetric difference between 1" & 1 1/2' Pipe. You can't compress a liquid...

There are two valves feeding each engine on Hancock's boat. The main raw water valve is a 1 1/2" full flow directly in line with the raw water pump. I placed a tee at at about mid point on the raw water hose to the engine raw water pump and dropped down to the valves seen above. To operate as crash pumps, the crash valves are FIRST opened and THEN the through hull valve is closed. When the bilge water is back under control, the through hole valve is RE-OPENED and THEN the crash valve is closed. At all times, the engine has a source of constant water, at full capacity, be it from the bilge or overboard...

Br,

Patrick

most be cabin fever on both ends i see you mention reopen the valves as a optimist not me i pull the e-perp,the crew is donning there survival suits and i have bang in with a may day.and have the crash valves open to buy that extra minutes with 3 -1500gpm and 3 1000 gpm pumps running the crew has the life raft in the water and i stay with the bert trying to get jp nearby on the radio those crash valves just delay the inevitable one minute and i would be a happy camper just knowing sombody is on there way.

capt.bob lico

bero13010473

bero13010473

randall had one of those days today not on the water in my truck.chest, ribs,stomach feel like the days of old -----boat racing.i hit black ice and went head on with a 3' diameter tree.custom dodge with cummins diesel power total wreck . air bag hit so hard i am in a world of hurt all over.

capt.bob lico

bero13010473

bero13010473

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

Well, I've got to remain somewhat of an optimist, in my fatalistic sort of way...

Literally hundreds, maybe thousands, of power boater every year find themselves facing a potential sinking. Some actually do sink, a lot get rescued while the boat is still just barely afloat, and probably the most manage to somehow find the cause of the water egress, plug the source, and get the water back to normal or near normal bilge levels.

More often than not the problem is an easy fix or temporary patch that allows a limp home to safety. Probably many, if not most, of these type situations can be traced back to poor maintenance. Improper bonding causing a broken fitting, old hoses that break, electrical failure due to faulty wiring causing the bilge pumps to fail, a failed seal on a shaft log, and, yup...., even old pumps that just wheeze their last gulp of water. (Often due to winding up too much mono, carelessly left in the bilge.)

The list is endless and the results can be the same. A sunk boat....

But, common sense, advance preparation, and a calm approach will save most boaters from an unexpected swim. And that does have to be prepared for too.

I put the engine driven crash pump high on the list of advance preparation and properly installed and operated, these pumps can keep even a badly damaged boat afloat for a long time. Enough, maybe, to wait for help to arrive without diving into the brink. Enough to maybe even get home under your own power.

The sinking that occurs in a short few minutes are relatively rare. Rogue seas the rip off a fore deck, struck objects that rip a hole big enough to walk through, lightening strikes that blow out through hole fittings and disable engines at the same time, are obviously something that a crash pump can't counter. But again, these occurrences are not common place. Any more than plane crashes, that happen daily somewhere, but the percentages are very small when compared with the number of planes in the air at any given moment.

I have personally witnessed several boats that were legitimately sinking. The captains and crews didn't have a clue, were all panicking and dancing around like a bunch of school girls at a mouse convention.

All of these eye witness accounts were near coastal situations and rescue was close at hand. All were cases that the boat was heavily laden with water in the bilge, and one was even on fire. Every one of the boats were saved, before, and without, sinking and that was after the crew was transferred off. All saved by 5 -10 hp gas powered engines coupled to submersible pumps. Standard equipment on CG & commercial tow boats.

Had the captains and crews been prepared and equipped with their own engine driven crash pumps, (save for the one on fire), there probably would not have been a single May Day call.

Part of this voyeurism happened while working part time on a commercial tow vessel for two years and part from just fishing on the crowded rip off of S.E. Florida.

So the availability of a pair of 240 - 370 hp engines, rigged as crash pumps leaves me feeling all warm and fuzzy. Certainly, I'm not going to abandon ship with my crash pumps operating for less of a reason than a catastrophic event. That and the knowledge of how to deal with boat related emergencies. Remember my rant on "What If" games?

So.... Bob, enlarge those soda straws and stay onboard a few minutes longer, bring Phoenix limping back to the yard, jerk the cushion out of the hole in the bow, get your epoxy warmed up and start rehearsing your Sea Story about how you saved your own boat without buggin' those poor Coasties.

Br,

Patrick

Literally hundreds, maybe thousands, of power boater every year find themselves facing a potential sinking. Some actually do sink, a lot get rescued while the boat is still just barely afloat, and probably the most manage to somehow find the cause of the water egress, plug the source, and get the water back to normal or near normal bilge levels.

More often than not the problem is an easy fix or temporary patch that allows a limp home to safety. Probably many, if not most, of these type situations can be traced back to poor maintenance. Improper bonding causing a broken fitting, old hoses that break, electrical failure due to faulty wiring causing the bilge pumps to fail, a failed seal on a shaft log, and, yup...., even old pumps that just wheeze their last gulp of water. (Often due to winding up too much mono, carelessly left in the bilge.)

The list is endless and the results can be the same. A sunk boat....

But, common sense, advance preparation, and a calm approach will save most boaters from an unexpected swim. And that does have to be prepared for too.

I put the engine driven crash pump high on the list of advance preparation and properly installed and operated, these pumps can keep even a badly damaged boat afloat for a long time. Enough, maybe, to wait for help to arrive without diving into the brink. Enough to maybe even get home under your own power.

The sinking that occurs in a short few minutes are relatively rare. Rogue seas the rip off a fore deck, struck objects that rip a hole big enough to walk through, lightening strikes that blow out through hole fittings and disable engines at the same time, are obviously something that a crash pump can't counter. But again, these occurrences are not common place. Any more than plane crashes, that happen daily somewhere, but the percentages are very small when compared with the number of planes in the air at any given moment.

I have personally witnessed several boats that were legitimately sinking. The captains and crews didn't have a clue, were all panicking and dancing around like a bunch of school girls at a mouse convention.

All of these eye witness accounts were near coastal situations and rescue was close at hand. All were cases that the boat was heavily laden with water in the bilge, and one was even on fire. Every one of the boats were saved, before, and without, sinking and that was after the crew was transferred off. All saved by 5 -10 hp gas powered engines coupled to submersible pumps. Standard equipment on CG & commercial tow boats.

Had the captains and crews been prepared and equipped with their own engine driven crash pumps, (save for the one on fire), there probably would not have been a single May Day call.

Part of this voyeurism happened while working part time on a commercial tow vessel for two years and part from just fishing on the crowded rip off of S.E. Florida.

So the availability of a pair of 240 - 370 hp engines, rigged as crash pumps leaves me feeling all warm and fuzzy. Certainly, I'm not going to abandon ship with my crash pumps operating for less of a reason than a catastrophic event. That and the knowledge of how to deal with boat related emergencies. Remember my rant on "What If" games?

So.... Bob, enlarge those soda straws and stay onboard a few minutes longer, bring Phoenix limping back to the yard, jerk the cushion out of the hole in the bow, get your epoxy warmed up and start rehearsing your Sea Story about how you saved your own boat without buggin' those poor Coasties.

Br,

Patrick

great story thanks for taking the time to give me the real in and outs of boat disasters .most of my pessimism comes from the fact that the canyon is 72 miles from home limping back would put me against extraordinary odds. my best effort would to keep in contact with coasties and bring phoenix back wot. getting that first 3' out of the water as it nomally runs and hopfully the water would go to the stern with the 1500gpm and the 1000gpm pumping thru seperate 11/2" thru holes.all theory of course based on the no damage to props and shafts factor.bear in mind the starter solonoids are about 16" above inside keel mark.when salt water goes over starter solonoids 4/0 positive cable attactment point there will be one hell of a bang from all that availble amperage from battery bank.now you would be dead in the water.both engines down.the absolute best of maintenace of which is given to phoenix cannot keep me afloat.so it`s put my head between my legs and kiss my ass goodby or get my loved one off into the liferaft and i would stay aboard and try the little vhf to call jp.

capt.bob lico

bero13010473

bero13010473

I personaly don't support using the engine water pump as a crash pump.

The reason is if the water flow comming in is less than the required flow of the engine pump it will run dry and the pump impeller can be damaged in 30 seconds or less.

The lesser flow would require someone to be stationed at the valves to monitor the crash intake and switch back to standard pickup when the crash intakes run dry to prevent pump damage.

On a 31 where everything is out in the open and access to jump over board is easy in the event a fire breaks out which is a very real possibilty due to water causing an electrical short, but in a boat with an engine room below decks it would require a person to be in an area with not so easy access to an escape route with the noise of running engines and the elevated adrenalin could very well cause an unexperienced person to panic and get hurt of killed when the emergency is a minor one.

They make both electric clutch and manual clutch pumps that are crash specific.

The electric ones can be used with a float switch to have automatic engagement and disengagement that leaves the operator to monitor more inportant things such as radio communications, passenger questions and maintaining a heading toward land or a rescue craft.

Many people don't realize the amount of water flow it takes to keep an engine pump going without damage and without some type of strainer on the pickup, bilge debris is another concern.

Just my .02.

The reason is if the water flow comming in is less than the required flow of the engine pump it will run dry and the pump impeller can be damaged in 30 seconds or less.

The lesser flow would require someone to be stationed at the valves to monitor the crash intake and switch back to standard pickup when the crash intakes run dry to prevent pump damage.

On a 31 where everything is out in the open and access to jump over board is easy in the event a fire breaks out which is a very real possibilty due to water causing an electrical short, but in a boat with an engine room below decks it would require a person to be in an area with not so easy access to an escape route with the noise of running engines and the elevated adrenalin could very well cause an unexperienced person to panic and get hurt of killed when the emergency is a minor one.

They make both electric clutch and manual clutch pumps that are crash specific.

The electric ones can be used with a float switch to have automatic engagement and disengagement that leaves the operator to monitor more inportant things such as radio communications, passenger questions and maintaining a heading toward land or a rescue craft.

Many people don't realize the amount of water flow it takes to keep an engine pump going without damage and without some type of strainer on the pickup, bilge debris is another concern.

Just my .02.

bruce.....i ran the boat all summer on land with a hose and the crash valves. hours of operation and not even close to overheating. i understand your point but if its sink or pump...i'm pumping. i dont think it would get to that for one reason. my boat has two 2500GPH pumps. i filled the boat to the top of the oil pans and flipped the pumps on. 10 seconds to empty...two firehoses. i was surprised. it has two 500's for daily pumping. and i shop vac it after it rains...hey...i like dry.

I have a three way valve on each input raw water. One entrance for raw water and in case water come too much for some reason , I turn the handle to the second position and on that entrance its a hose connected to a thing on the bottom. To prevent litle water to the engine I can manage with the handle to pick water from the bottom and also raw water. Just in case.

Regards

Regards

Capt Patrick,

Just wanted to show you the NextGen 5.5 without the soundbox, with 1.5lb sounddown port outboard of a 250 6BTA. Also the battery & switch for Gen and Hyn. steering reservior all outboard of port engine but also have a smaller air box than what you normally install tho.

Also to counter balance the weight, outboard starboard is a 4D battery & 4 bank battery charger with the other 4D battery downunder the center walk where the raw water pick ups are.

Just behind the vent hose at the top right is bottom of my air box 4x11, the wiring has been secured better than this picture shows.

[/img]

[/img]

R,

DQ

Just wanted to show you the NextGen 5.5 without the soundbox, with 1.5lb sounddown port outboard of a 250 6BTA. Also the battery & switch for Gen and Hyn. steering reservior all outboard of port engine but also have a smaller air box than what you normally install tho.

Also to counter balance the weight, outboard starboard is a 4D battery & 4 bank battery charger with the other 4D battery downunder the center walk where the raw water pick ups are.

Just behind the vent hose at the top right is bottom of my air box 4x11, the wiring has been secured better than this picture shows.

[/img]

[/img]R,

DQ

1967 Hull #315-605 FBC ---<*)((((><(

"IN GOD WE TRUST"

'Life may be the party we hoped for...but while we are here we might as well fish'!

"IN GOD WE TRUST"

'Life may be the party we hoped for...but while we are here we might as well fish'!

Who is online

Users browsing this forum: Bing [Bot] and 338 guests