rudder shelf material

Moderators: CaptPatrick, mike ohlstein, Bruce

rudder shelf material

Hi guys, I cannot decide what material to use for rudder shelves, either it be the starboard for laminates, or plywood. Capt. Pat did not specify which is better, just diff. techniques for each. I do like the idea of "no rot"

materials, but plywood seems maybe a bit easier to get final result. Any thoughts? Thanks for input. Rocky.

materials, but plywood seems maybe a bit easier to get final result. Any thoughts? Thanks for input. Rocky.

- Brewster Minton

- Senior Member

- Posts: 1795

- Joined: Jun 30th, '06, 07:44

- Location: Hampton Bays NY

- Contact:

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

Plywood will be fine as long as it's fully enclapsulated in epoxy fiberglass and all holes, (shaft hole & bearing bolt holes), are sleeved with pcv pipe epoxied in place. Again see: Hardware Mounting in Composites

For the maximum strength of your rudder shelf, laminate two 1/2" pieces of plywood face to face. Notice that the plywood usually has some warp to it, so laminate the pieces so the warps are opposing. This will effectively counteract the warp, resulting in a flat, straight 1" stock to work from.

For the maximum strength of your rudder shelf, laminate two 1/2" pieces of plywood face to face. Notice that the plywood usually has some warp to it, so laminate the pieces so the warps are opposing. This will effectively counteract the warp, resulting in a flat, straight 1" stock to work from.

Rocky-

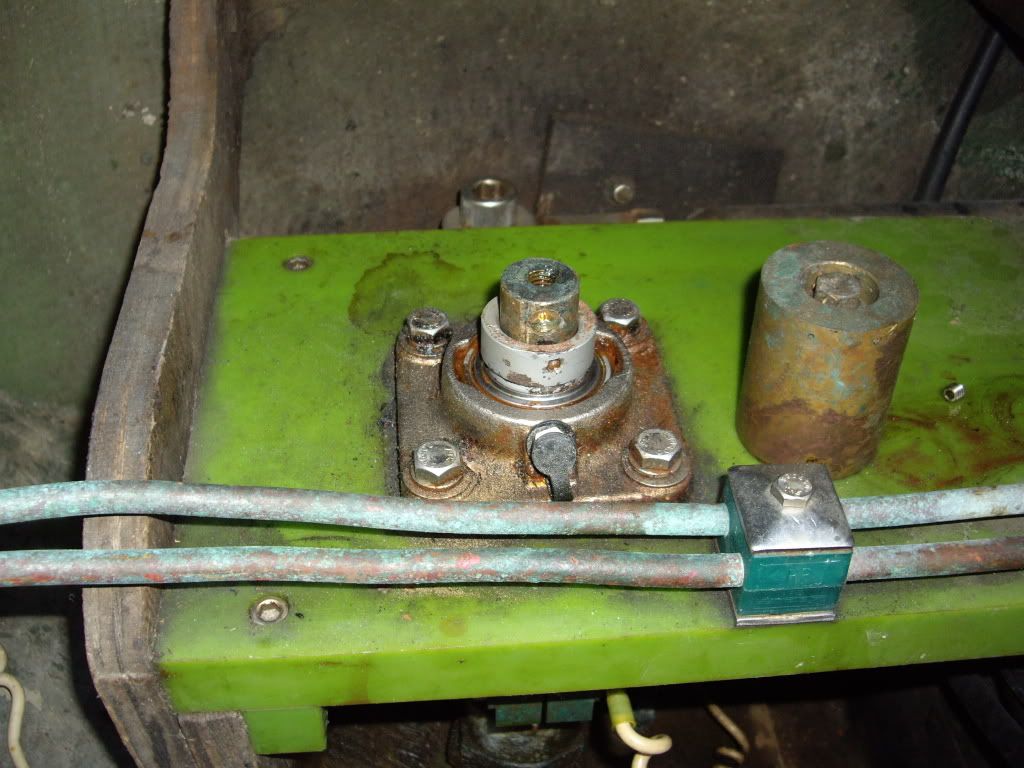

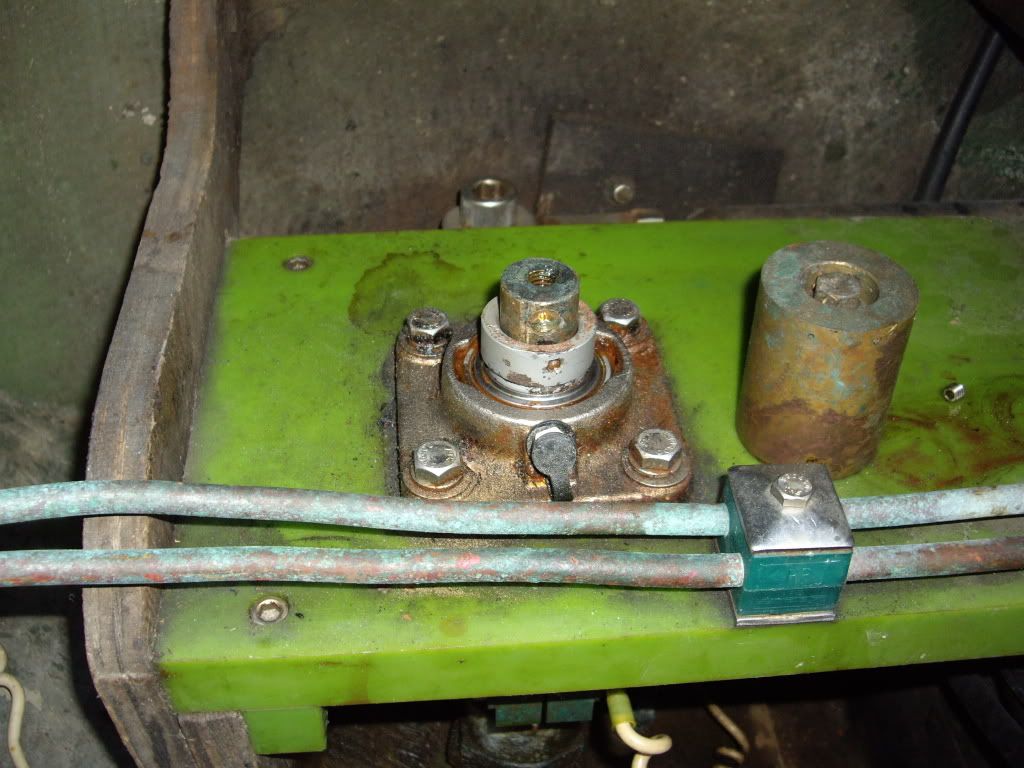

If I did this right, there is a picture of the set up on my boat. The guy 2 owners back did this work, It is some sort of structual polymer and is pretty strong. Cleans up nice and seems to be very stable. Also you can drill and tap into it. If you want, I can try to find out exactly what the material is.

If I did this right, there is a picture of the set up on my boat. The guy 2 owners back did this work, It is some sort of structual polymer and is pretty strong. Cleans up nice and seems to be very stable. Also you can drill and tap into it. If you want, I can try to find out exactly what the material is.

Giff

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

In the immortal words of Orson Wells, "Drink No Wine Before It's Time"My wife is asking when this boat will hit the water...

Or said differently, "Ride No Boat 'Til It's Worthy Of Float"

Remember, your boat is in direct competition with her wardrobe maintenance. Every once in a while, (6 months max), buy her a nice present.

A pair of $200 diamond ear rings and a night out at a good restaurant can work miracles while you're squandering your life savings on a 40 year old boat.

- MikeD@Lightningshack

- Senior Member

- Posts: 127

- Joined: Jul 4th, '06, 16:52

- Location: Manasquan, NJ

- Contact:

I followed Capt. Pat's advice and was very happy with the results.

To economize the work I made a complete 4'x8' marine grade laminate board. I used 2 1/2" sheets of marine plywood with expoxy and roven fiberglass core. The picture below is the board in production. If you look close you can see hundreds of screws used to hold the boards together while the internal epoxy cured. Next was epoxy and fiber glass each side. After that it is just a matter of having a big enough table saw to rip the pieces you need.

I was able to use this 1 board for the rudder table and for backing plates for the struts. Still have a chunk of it in my shed. After cutting and assembling the structures the edges need to be sealed with expoxy and or glass.

Heavy, but should last forever. Looks a lot better than starboard, and with a coat of Awlgrip you'll be able to keep it looking new for a long time.

To economize the work I made a complete 4'x8' marine grade laminate board. I used 2 1/2" sheets of marine plywood with expoxy and roven fiberglass core. The picture below is the board in production. If you look close you can see hundreds of screws used to hold the boards together while the internal epoxy cured. Next was epoxy and fiber glass each side. After that it is just a matter of having a big enough table saw to rip the pieces you need.

I was able to use this 1 board for the rudder table and for backing plates for the struts. Still have a chunk of it in my shed. After cutting and assembling the structures the edges need to be sealed with expoxy and or glass.

Heavy, but should last forever. Looks a lot better than starboard, and with a coat of Awlgrip you'll be able to keep it looking new for a long time.

-

charlie falkenstein

- Senior Member

- Posts: 83

- Joined: Jul 26th, '06, 18:10

- Location: mt. laurel n.j.

- MikeD@Lightningshack

- Senior Member

- Posts: 127

- Joined: Jul 4th, '06, 16:52

- Location: Manasquan, NJ

- Contact:

-

Tony Meola

- Senior Member

- Posts: 7036

- Joined: Jun 29th, '06, 21:24

- Location: Hillsdale, New Jersey

- Contact:

If you want structural fiberglass for the shelf check out Mcmaster Carr. Thats were I ordered mine. It is the same style as Giff's but his does not look like its made out of glass. We also used Fiberglass angles to attach it to the verticle supports. Two people can stand on it and no flex

Capt. Pat. $200 diamond earings in this day and age. You have been single too long and living in Texas away from it all. With $200 earings, you better have a magnifying glass so she can see the diamone. Get cubic Zircs and lie a lot and just hope she never gets it appraised until after you are long gone.

Capt. Pat. $200 diamond earings in this day and age. You have been single too long and living in Texas away from it all. With $200 earings, you better have a magnifying glass so she can see the diamone. Get cubic Zircs and lie a lot and just hope she never gets it appraised until after you are long gone.

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

Boy, Tony, now you're lookin' for real trouble. CZ? They can be spotted 1/2 a block away... Especially by a woman. Them gals know their rocks.Get cubic Zircs and lie a lot and just hope she never gets it appraised until after you are long gone.

Now I didn't say that you could buy a couple of Hope Diamonds for 2 bucks, but .25 ctw studs can be had for that including shipping. It's the thought that counts! Oh, and the good resturant? Appleby's should go nicely with those teeny-weeny little sparklers...

Hey, ya' can't be too lose with that boat squandering money... Remember, it's a Bertram.

Nope, nowhere near long enough!You have been single too long

-

Tony Meola

- Senior Member

- Posts: 7036

- Joined: Jun 29th, '06, 21:24

- Location: Hillsdale, New Jersey

- Contact:

Capt. Pat

My wife loves the boat and is great fishing partner, as long as we are not out of sight of land. The offshore stuff is guys only. She said if I could have her dropped in by Helicopter then she would go.

She is pretty good about the repower has not asked how much yet but knows its not cheap.

One other good point, she is frugal and I never worry about what she buys or spends, since its only when she feels she really needs it.

So once the repower is done, my gift to her will be custom rod to replace the one the rod she had that broke.

My wife loves the boat and is great fishing partner, as long as we are not out of sight of land. The offshore stuff is guys only. She said if I could have her dropped in by Helicopter then she would go.

She is pretty good about the repower has not asked how much yet but knows its not cheap.

One other good point, she is frugal and I never worry about what she buys or spends, since its only when she feels she really needs it.

So once the repower is done, my gift to her will be custom rod to replace the one the rod she had that broke.

- MikeD@Lightningshack

- Senior Member

- Posts: 127

- Joined: Jul 4th, '06, 16:52

- Location: Manasquan, NJ

- Contact:

in all the years of watching this board that is the most impressive picture i have ever seen.wow they don`t make them like that on long island.you have a gem,what a lucky guy!!!incidently would be 1/2 caret each about 2000.00 and that might get you your lunch and a kiss before you go to the boat.

capt.bob lico

bero13010473

bero13010473

- Capt Dick Dean

- Senior Member

- Posts: 336

- Joined: Dec 17th, '06, 15:33

- Location: Long Island, N.Y.

- Contact:

I rebuilt my shelves last winter. I used wood - solid 3/4 in cherry. I took pictures of Capt Harv's set up. It is first rate. But my way was quick and cheap.

Speaking of other matters, I took 1 inch of pitch out of my props last summer after I was told that I was over proped. We had 4 blade 18x18 wheels. The RPM's jumped 400. The boat seems to run better with less strain at any given speed. I feel that I'm burning less fuel at 2900 RPM rather than 2700 RPM Maybe this is like the drinking. I do know that my car runs better after it gets washed.

Speaking of other matters, I took 1 inch of pitch out of my props last summer after I was told that I was over proped. We had 4 blade 18x18 wheels. The RPM's jumped 400. The boat seems to run better with less strain at any given speed. I feel that I'm burning less fuel at 2900 RPM rather than 2700 RPM Maybe this is like the drinking. I do know that my car runs better after it gets washed.

A/K/A El Gaupo

Who is online

Users browsing this forum: Bing [Bot] and 341 guests