Rust control

Moderators: CaptPatrick, mike ohlstein, Bruce

- John Jackson

- Senior Member

- Posts: 161

- Joined: Jul 19th, '06, 22:39

- Location: Point Pleasant Beach, NJ

Rust control

Anyone have any ideas on the best way to repaint/recoat Cummins engines? After a year of use I have some rust spots and the manifold seems the worst. It looks like the paint on all of the hot spots has taken a beatin' from the heat, getting a little brown/yellowed. Plus various rust spots. Nothing bad, but I want to stay on top of it.

Is it enough to wire brush it to rough it up and then touch up? Sand to bare metal? Looks like taking down all of the affected areas to bare metal would be a major project and hard to do. Anything else I should know?

What is the best paint to use?

JP, will Rob do it for beer? He seems pretty handy with paint.

Thanks for the help. JJJ

Is it enough to wire brush it to rough it up and then touch up? Sand to bare metal? Looks like taking down all of the affected areas to bare metal would be a major project and hard to do. Anything else I should know?

What is the best paint to use?

JP, will Rob do it for beer? He seems pretty handy with paint.

Thanks for the help. JJJ

-

Tony Meola

- Senior Member

- Posts: 7036

- Joined: Jun 29th, '06, 21:24

- Location: Hillsdale, New Jersey

- Contact:

John

A posting on Boat Diesal.com from about 6 months ago said to use Krylon Ivory or Diamond White from Ford. They also said to watch the spray cans since they have a lot of thinners in them, they could soften the Cummins paint. Evidently the paint on the Cummins is pretty cheap. Go figure, build a great engine and then save a few bucks on paint. You would think they would do a better job at that. Tony Meola

A posting on Boat Diesal.com from about 6 months ago said to use Krylon Ivory or Diamond White from Ford. They also said to watch the spray cans since they have a lot of thinners in them, they could soften the Cummins paint. Evidently the paint on the Cummins is pretty cheap. Go figure, build a great engine and then save a few bucks on paint. You would think they would do a better job at that. Tony Meola

- In Memory Walter K

- Senior Member

- Posts: 2912

- Joined: Jun 30th, '06, 21:25

- Location: East Hampton LI, NY

- Contact:

Sand down loose edges of paint on rust/peeling spots. Brush on an acid product called Ospho. The area's exposed metal should turn black. Let dry and spray with Cummins' spray paint of the matching color. Cummins spray paint costs half the price at a truck supply place...as does the serpentine belt. Walter

I use the products from POR 15 and have been generally satisfied with them. I would put clean it with Marine Clean (also from POR 15) . POR-15 over the rusted spots. acid etch prime the rest and paint with whichever paint satisfies you (you don't have to use their engine paint). They have an engine paint kit. http://www.por15.com/prodinfo.asp?grp=EPK&dept=11

Rawleigh

1966 FBC 31

1966 FBC 31

John,

Its pretty much wire brush wipe off XIM primer and then Tempo White for us. You'll never get the manifold to stop burning cause that's what its doing- burning the paint.

Block heaters help reduce rust by keeping things dry.

You gotta stop using the boat so often, you've run the paint off the motors.

The biggest drag is pulling the side panels off to do the touch up.

Its pretty much wire brush wipe off XIM primer and then Tempo White for us. You'll never get the manifold to stop burning cause that's what its doing- burning the paint.

Block heaters help reduce rust by keeping things dry.

You gotta stop using the boat so often, you've run the paint off the motors.

The biggest drag is pulling the side panels off to do the touch up.

KR

JP

1977 RLDT "CHIMERA"

JP

1977 RLDT "CHIMERA"

- Brewster Minton

- Senior Member

- Posts: 1795

- Joined: Jun 30th, '06, 07:44

- Location: Hampton Bays NY

- Contact:

They used to but market competition and rising prices, corners have to be cut so people still buy.You would think they would do a better job at that

Crappy paint is the norm on all engines except the Steyer.

Every new engine I install gets a rough up, wipe down and new paint applied for a heavier coat.

Randall,

Really nice to see a painted engine without the floor to match.

BTW, tywraps on even 7 or 8mm silicon plug wires is a no/no.

They shouldn't touch any metal or coolant hoses either otherwise spark energy can be lost.

- John Jackson

- Senior Member

- Posts: 161

- Joined: Jul 19th, '06, 22:39

- Location: Point Pleasant Beach, NJ

-

Ed Millian

- Posts: 13

- Joined: Jun 29th, '06, 11:42

- Location: Boston Mass.

Rust removal

Hi John

I would get a needle scaler . They are great a gettting into tight spots and remove heavy rust . Do not use on light metal parts. You can get them sometimes from Harbor freight tools for 40$ . My boat has 1968 blocks and this tool is the reason why they are still around. Ear protection , respirator and someone you don't like and the engine will clean up nice.

Ed Millian

CHOCORUA 31 FBC 1962

I would get a needle scaler . They are great a gettting into tight spots and remove heavy rust . Do not use on light metal parts. You can get them sometimes from Harbor freight tools for 40$ . My boat has 1968 blocks and this tool is the reason why they are still around. Ear protection , respirator and someone you don't like and the engine will clean up nice.

Ed Millian

CHOCORUA 31 FBC 1962

- John Jackson

- Senior Member

- Posts: 161

- Joined: Jul 19th, '06, 22:39

- Location: Point Pleasant Beach, NJ

Randall,

Most factory and oem plug wires have a core of carbon fiber to reduce rf noise. The down side is the resistance of the carbon fiber and reduced spark energy.

Solid wires are best but would produce all kinds of noise in your radios, and can affect systems in cars such as the computers, abs systems and the such and solid wires are really only used in the racing environment.

Silicones have a resistivity of around 10 ohms per meter.

Given a core diameter of 2mm and insulation diameter of 7mm that's only 2.5mm of insulation from the core to the outside world and most wires actually leak a considerable amount of energy to their outer shell.

The bigger the spark energy the more leakage. Having another wire, metal or coolant hose touching can lead to some of this energy either being shot to grouind or down another wire leading to misfiring(grounding at the plug).

The decreased spark energy in the firing wire can lead to poor cumbustion which wastes gas and creates power loss.

There's a reason on high performance engines that they use stand offs and grommets around the wire contact point.

Now on marine engines like yours where the wires run between the head and manifold the only way to fix that is to use a longer wire set and go down the back or front of the manifolds(depending on engine brand and dist location).

Now the question is how much reward will I see by going to all that trouble and some expense to create a set of wires that hangs free.

Well when gas was .80 cents a gallon, it was no big deal. But now that gas is predicted to be 4 bucks a gallon this spring and summer due to the change over to summer blends and the current shortage of the additive alkylate which replaced MTBE, it could be worthwhile.

If you use 300 gallons in a season at 4 bucks, thats 1200 dollars.

Savings of 10% or more have been known to occur by correctly stringing your wires. Thats 120 bucks. In one season you'd pay for the new wires.

Now this takes into consideration that the engine is in good shape without any internal problems.

I have also seen engines with chronic misses at idle be corrected by proper wire runs.

Just food for thought.

Most factory and oem plug wires have a core of carbon fiber to reduce rf noise. The down side is the resistance of the carbon fiber and reduced spark energy.

Solid wires are best but would produce all kinds of noise in your radios, and can affect systems in cars such as the computers, abs systems and the such and solid wires are really only used in the racing environment.

Silicones have a resistivity of around 10 ohms per meter.

Given a core diameter of 2mm and insulation diameter of 7mm that's only 2.5mm of insulation from the core to the outside world and most wires actually leak a considerable amount of energy to their outer shell.

The bigger the spark energy the more leakage. Having another wire, metal or coolant hose touching can lead to some of this energy either being shot to grouind or down another wire leading to misfiring(grounding at the plug).

The decreased spark energy in the firing wire can lead to poor cumbustion which wastes gas and creates power loss.

There's a reason on high performance engines that they use stand offs and grommets around the wire contact point.

Now on marine engines like yours where the wires run between the head and manifold the only way to fix that is to use a longer wire set and go down the back or front of the manifolds(depending on engine brand and dist location).

Now the question is how much reward will I see by going to all that trouble and some expense to create a set of wires that hangs free.

Well when gas was .80 cents a gallon, it was no big deal. But now that gas is predicted to be 4 bucks a gallon this spring and summer due to the change over to summer blends and the current shortage of the additive alkylate which replaced MTBE, it could be worthwhile.

If you use 300 gallons in a season at 4 bucks, thats 1200 dollars.

Savings of 10% or more have been known to occur by correctly stringing your wires. Thats 120 bucks. In one season you'd pay for the new wires.

Now this takes into consideration that the engine is in good shape without any internal problems.

I have also seen engines with chronic misses at idle be corrected by proper wire runs.

Just food for thought.

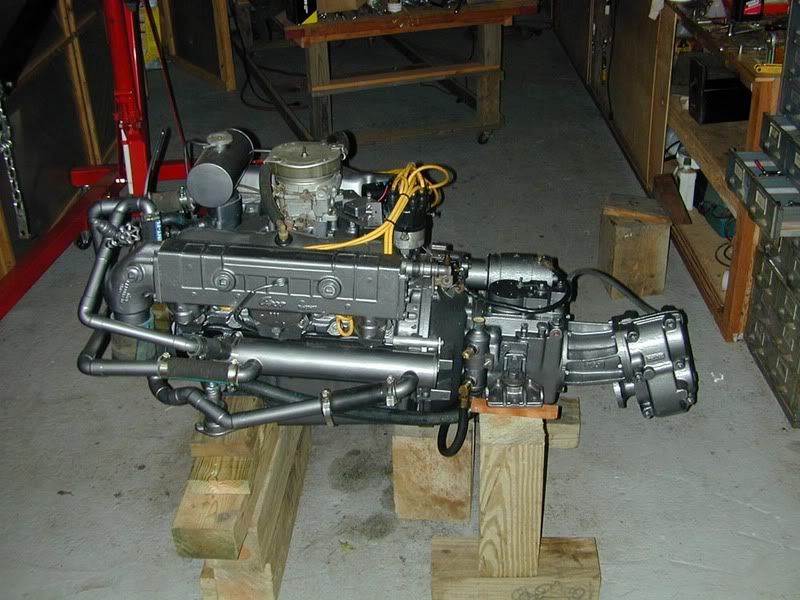

John I did my Cummins with Rustoleum and use por-15 for and rust spots also 2 years later still looks great. But are talking about the exhaust manifold where its coming of the head? It gets hot there and nothing that I know of will stay in that area its about 1 1.5" worth! See below picture.

These are 1998 330 b's

These are 1998 330 b's

very nice engine install and condition.

Randall,

Using seperators for the wires instead of zip ties is a good start. They can be had cheap at an auto parts store for your wire diameters.

Additional insulating with rubber won't do much. Due to the energy of the spark force most insulators don't work well. The best of all for this type of energy is air gap. Think energy in terms of Jacob's Ladder. Not as strong in really stock systems, but the weaker the spark at the plug, the less fuel is burned and the power is produced which makes you open the throttle more, burn more fuel to produce more power.

Kind of dog chasing its tail.

Wires have become such an antiquated system now that individual plug coils and short heavy wall plug connectors are used to produce very strong sparks to burn fuel better so you make more power with less fuel and get better mileage.

The one down fall to this system on some engines is the plugs are recessed into a pocket in the rocker cover that have no way of draining. You get water and dirt build up that can short out cylinders.

Its very important if a car has this type of setup that the plug wells be kept clean and dry.

My daughter had this problem on her SUV when it would rain, the plug pockets would fill with water and the engine would rough idle and misfire and the gas milage was lousy for a couple of days till the water evaporated and then would run fine.

I fixed it by using clear silicon at the top of the well to seal the hole.

Randall,

Using seperators for the wires instead of zip ties is a good start. They can be had cheap at an auto parts store for your wire diameters.

Additional insulating with rubber won't do much. Due to the energy of the spark force most insulators don't work well. The best of all for this type of energy is air gap. Think energy in terms of Jacob's Ladder. Not as strong in really stock systems, but the weaker the spark at the plug, the less fuel is burned and the power is produced which makes you open the throttle more, burn more fuel to produce more power.

Kind of dog chasing its tail.

Wires have become such an antiquated system now that individual plug coils and short heavy wall plug connectors are used to produce very strong sparks to burn fuel better so you make more power with less fuel and get better mileage.

The one down fall to this system on some engines is the plugs are recessed into a pocket in the rocker cover that have no way of draining. You get water and dirt build up that can short out cylinders.

Its very important if a car has this type of setup that the plug wells be kept clean and dry.

My daughter had this problem on her SUV when it would rain, the plug pockets would fill with water and the engine would rough idle and misfire and the gas milage was lousy for a couple of days till the water evaporated and then would run fine.

I fixed it by using clear silicon at the top of the well to seal the hole.

Actually, there is a paint that will stick to the manifold ports... Try the Rustoleum high temperature paint: http://www.rustoleum.com/CBGProduct.asp?pid=112

Color may not be perfect match, but at least you won't have brown.

ag

Color may not be perfect match, but at least you won't have brown.

ag

Not everybody can own a Bertram 31

Email: algillen@yahoo.com

Email: algillen@yahoo.com

Who is online

Users browsing this forum: No registered users and 386 guests