Exhaust size from Turbo??

Moderators: CaptPatrick, mike ohlstein, Bruce

Exhaust size from Turbo??

So it time to start laying out the exhaust.

Cummins says minimum size for the 6BT is 4", I'm going 5" with mufflers.

Running exhaust from the Port side is pretty tight coming from the factory dump...dump is also 3.5"???

Kinda odd when they call for 4" as the min...

So anyway the question is how long can I run the 3.5" before having to bump it up to 5".

3-1/2" hose and fiberglass tube is easier to squeeze in and around the transmission, floor and bulkhead then 5" would be.

Kinda last question...in all the pictures and discussions I do not recall anyone talking about using reducers to go from the turbo dump/shower head to their exhaust hose.

Why is mine 3-1/2" is is it normal to be down smaller?

Last last question--- Making surge tubes and reducers(enlargers) using polyester resin for the heat.

As it is not as strong...does it make sense to finish off with a layer of epoxy for added strenght?

Cummins says minimum size for the 6BT is 4", I'm going 5" with mufflers.

Running exhaust from the Port side is pretty tight coming from the factory dump...dump is also 3.5"???

Kinda odd when they call for 4" as the min...

So anyway the question is how long can I run the 3.5" before having to bump it up to 5".

3-1/2" hose and fiberglass tube is easier to squeeze in and around the transmission, floor and bulkhead then 5" would be.

Kinda last question...in all the pictures and discussions I do not recall anyone talking about using reducers to go from the turbo dump/shower head to their exhaust hose.

Why is mine 3-1/2" is is it normal to be down smaller?

Last last question--- Making surge tubes and reducers(enlargers) using polyester resin for the heat.

As it is not as strong...does it make sense to finish off with a layer of epoxy for added strenght?

Re: Exhaust size from Turbo??

Carl,

I will send you some pics from the beach here, Im sure you’ll expedite the order lol!

I will send you some pics from the beach here, Im sure you’ll expedite the order lol!

1973 B28 FBC/2007 4LHA STP's - "Phantom Duck" - Hull "BER 00794 1172"

- mike ohlstein

- Site Admin

- Posts: 2394

- Joined: Jun 29th, '06, 11:39

- Location: So many things seem like no-brainers until you run into someone with no brain.

- Contact:

Re: Exhaust size from Turbo??

Properly done, polyester is just as strong as epoxy. It's just not as good an adhesive. If you're going to try to reenforce a polyester tube, sure, use epoxy. But those tubes are pretty strong to start with. Just make sure that you use a 90 degree Tee, so that water will rush past the 90.Carl wrote:Last last question--- Making surge tubes and reducers(enlargers) using polyester resin for the heat.

As it is not as strong...does it make sense to finish off with a layer of epoxy for added strenght?

-

Tony Meola

- Senior Member

- Posts: 7036

- Joined: Jun 29th, '06, 21:24

- Location: Hillsdale, New Jersey

- Contact:

Re: Exhaust size from Turbo??

Carl

We had to open up the bulkhead to allow for the 5 inch exhaust. I will take s cvoupkke of pics for you over the weekend.

We had to open up the bulkhead to allow for the 5 inch exhaust. I will take s cvoupkke of pics for you over the weekend.

1975 FBC BERG1467-315

Re: Exhaust size from Turbo??

mike ohlstein wrote: Just make sure that you use a 90 degree Tee, so that water will rush past the 90.

http://www.bertram31.com/hancock/eng_cm ... s/exhaust/

https://www.fisheriessupply.com/centek-surge-chamber

Interesting, 90 deg wasn't even on my option table.

Just about all the surge tube setups I have seen have exhaust coming in at 45 degrees as in the above link.

90 makes sense, but also its a 90 and I'm doing my best to keep back pressure down.

I thought I recall the surge tube acted sort of like a shock absorber...water rushing in would compress the air in the surge tube then push water directly back...or something to that effect.

...just when I thought I had it all figured out.

Re: Exhaust size from Turbo??

STOP,STOP,STOP you off on a tangent!!!! step one you use the gasket to the turbo output and take to machinr shop----ha ,ha ok take it to your shop the ID with match turbo at 3 1/2" ID and the od will be 4" put a neck on that piece about 1' .so now you have flange with bolt patern (4 bolts) and a 1" neck sticking out now a 90 degree fitting and of course you are using 316 ss for all of this next another 70 degre fitting your exhaust is now aiming at the port side then you need a straight nipple and another 90 degree bent into a 4x5" sprinkler head you can buy from EXHAUST MANIFOLD famingdale long island ny . from sprinkler head to muffler in SILICONE BLUE no subsitude . anybody that tell you about surge tubes the answer is f-ck off, they have no clue,and stop reading books. the pieces i told you about will have to be covered in insulation up to sprinkler head. so on both port and starboard you go up from turbo within 1" of engine box cover andthen you go down to out side of boar along chine with the use of a MINIMAX muffler from centex.both sides with run along chine with a down hill slope from engine to exhaust output in transom.when you use that 3 1/2" to 4" adapter on turbo along with the straight pipe you will pick up around 6 HP. yea i had two cummins service people come to my boat and ask permision to examine so i let them.the sprinkler head will have a 1 14" output to your heat exchanger output. any questions PM me i could get you anything and drop off on way to the 38' bertram in nj.

capt.bob lico

bero13010473

bero13010473

-

Tony Meola

- Senior Member

- Posts: 7036

- Joined: Jun 29th, '06, 21:24

- Location: Hillsdale, New Jersey

- Contact:

Re: Exhaust size from Turbo??

Carl

If you decide to run the exhaust down the outside alley instead of in the shaft alley, you do not need to touch the exhaust flange through the transom. Run the exhaust in the outside alley, then as you near the transom, use a 5 inch 45 degree elbow to turn the exhaust into the shaft alley then another 45 to line up with the exhaust flange.

That is what JJ did on his boat. Except he was running 270 Cummins and upped the exhaust to 6 inches. Since you have the 220 Cummins, you should be good to go with 5 inch exhaust, since cummins is looking for 4 inch.

If you decide to run the exhaust down the outside alley instead of in the shaft alley, you do not need to touch the exhaust flange through the transom. Run the exhaust in the outside alley, then as you near the transom, use a 5 inch 45 degree elbow to turn the exhaust into the shaft alley then another 45 to line up with the exhaust flange.

That is what JJ did on his boat. Except he was running 270 Cummins and upped the exhaust to 6 inches. Since you have the 220 Cummins, you should be good to go with 5 inch exhaust, since cummins is looking for 4 inch.

1975 FBC BERG1467-315

Re: Exhaust size from Turbo??

Bob,

I know your design pretty well and cannot argue with any of it. My clock is ticking away, mechanic helping me moves to Florida in a couple weeks, he's the guy to work out any bugs that will come up on sea trials. So it's do it simple, straight forward and get boat in the water, see how motors run, see how boat performs...use a bit and figure a plan for next season, provided all goes well.

Next year I already have risers or new elbows on the list, then sound insulation, deck and motor box work, connecting trolling valve to start. When I get motor boxes back in boat I can look into running dry over...express boxes are different then yours, they are ribbed for access hatchs.

Tony- going down shaft alley with exhaust, mufflers and new 5" transom flanges. Supposedly a special order from Buck Algonquin for 15 deg angle flanges as shown on website/catalog. After 3 weeks they came in last week. Went to install on Thursday...open box, they are straight. Put call into a Buck and they told me they don't make 5" angled flanges and not sure why they had pictures of them under 5". So a little saw and weld...15 degree flanges.

I know your design pretty well and cannot argue with any of it. My clock is ticking away, mechanic helping me moves to Florida in a couple weeks, he's the guy to work out any bugs that will come up on sea trials. So it's do it simple, straight forward and get boat in the water, see how motors run, see how boat performs...use a bit and figure a plan for next season, provided all goes well.

Next year I already have risers or new elbows on the list, then sound insulation, deck and motor box work, connecting trolling valve to start. When I get motor boxes back in boat I can look into running dry over...express boxes are different then yours, they are ribbed for access hatchs.

Tony- going down shaft alley with exhaust, mufflers and new 5" transom flanges. Supposedly a special order from Buck Algonquin for 15 deg angle flanges as shown on website/catalog. After 3 weeks they came in last week. Went to install on Thursday...open box, they are straight. Put call into a Buck and they told me they don't make 5" angled flanges and not sure why they had pictures of them under 5". So a little saw and weld...15 degree flanges.

-

Tony Meola

- Senior Member

- Posts: 7036

- Joined: Jun 29th, '06, 21:24

- Location: Hillsdale, New Jersey

- Contact:

Re: Exhaust size from Turbo??

Carl

Before I leave the boat I will harken a pic of how mine run.

Before I leave the boat I will harken a pic of how mine run.

1975 FBC BERG1467-315

- mike ohlstein

- Site Admin

- Posts: 2394

- Joined: Jun 29th, '06, 11:39

- Location: So many things seem like no-brainers until you run into someone with no brain.

- Contact:

Re: Exhaust size from Turbo??

I stand corrected.

Re: Exhaust size from Turbo??

mike the cummins guys were standing there in amazement. i feel it was a foolish act but i was determine and never do it again. two cumminn technicians and northeast rep. were in the cockpit and i took boat into bay. i put the boat into reverse with the rudder indicator at "0" then push the throttles dow full speed in reverse (31 Bertram does not like going that fast in reverse ) can easily whip around no keel and rudders are useless in reverse but if you touch that wheel i am sure i would be thrown off the bridge.i try every every possible way to slug the motors to no avail. you cannot slug the motors with this up and then down reverse loop exhaust design.they put their gauges on the turbo output (exhaust) and the HG was close to 0 like no back pressure. i have 6" all the way from sprinkler head to exhaust output at transom.this exhaust design not in 6' but the up and over i copy from Tony Athens at seaborn marine in CA. the straight pipe for scavenging effect i get from race cars.

capt.bob lico

bero13010473

bero13010473

Re: Exhaust size from Turbo??

the starboard side adapter off turbo from 3 3/4'" output ID. to 4" ID at90 degrees than another long sweep 70 degrees to outside to straight pipe (all hot pipe wrapped" then sprinkler straight down WILL last 100 years this position and about 15 years or so OEM 5" exhaust sprinkler installed at 45 degree angle obviously burns out on top from lack of water, at least it is made of 316 SS. Caterpillar the best with everdor but mounted on angle also. after sprinkler 70 degrees with 5" blue silicon hose to muffler

CENTEK INDUSTRIES MINIMAX PART #1050500 input 5" and output 5" outside did. 8.38 and i9 inches long------no substitution for flawless surge protection going in reverse in a hurricane !tap on photo to get full picture

CENTEK INDUSTRIES MINIMAX PART #1050500 input 5" and output 5" outside did. 8.38 and i9 inches long------no substitution for flawless surge protection going in reverse in a hurricane !tap on photo to get full picture

Last edited by bob lico on Aug 1st, '19, 07:40, edited 2 times in total.

capt.bob lico

bero13010473

bero13010473

Re: Exhaust size from Turbo??

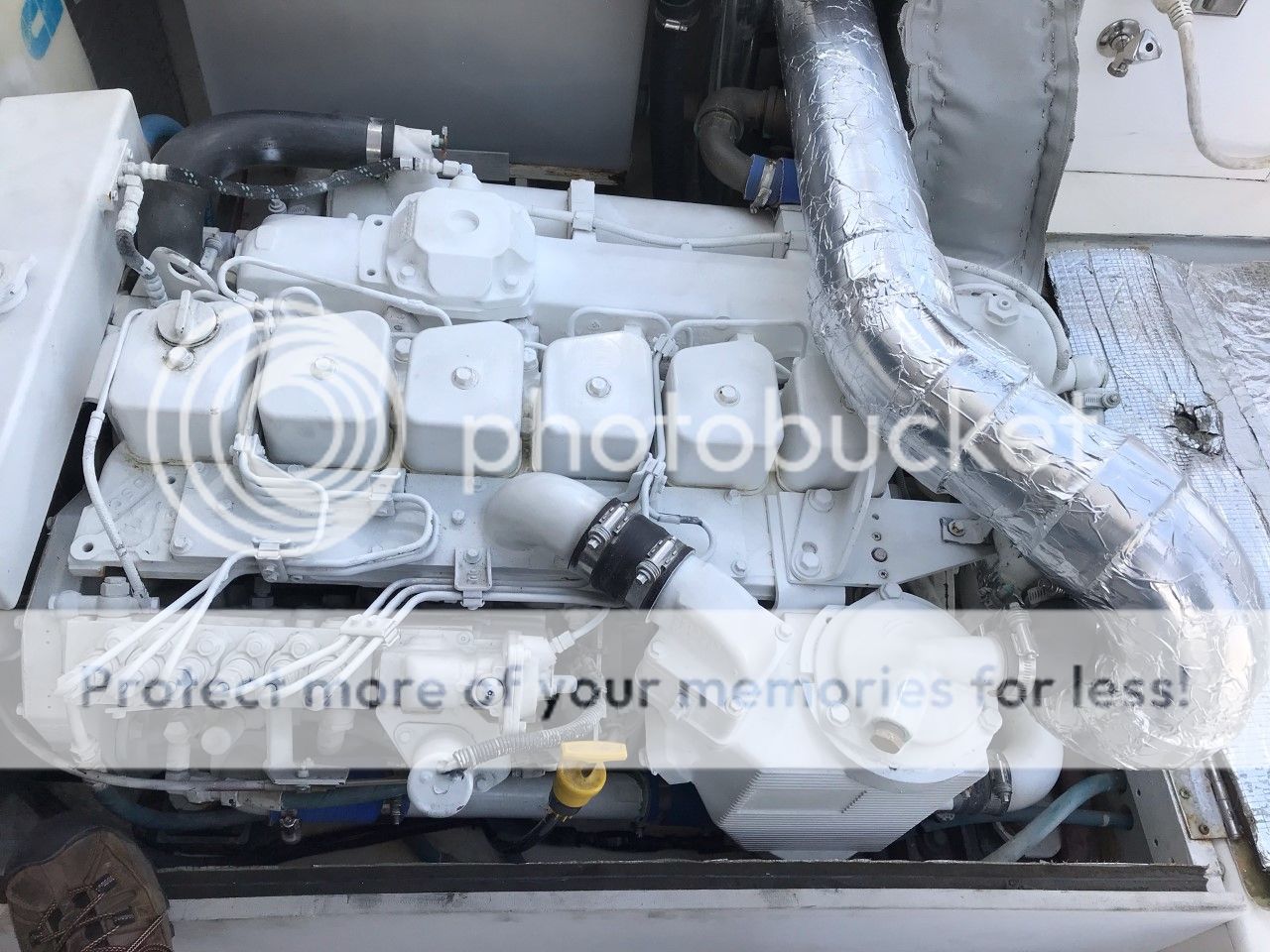

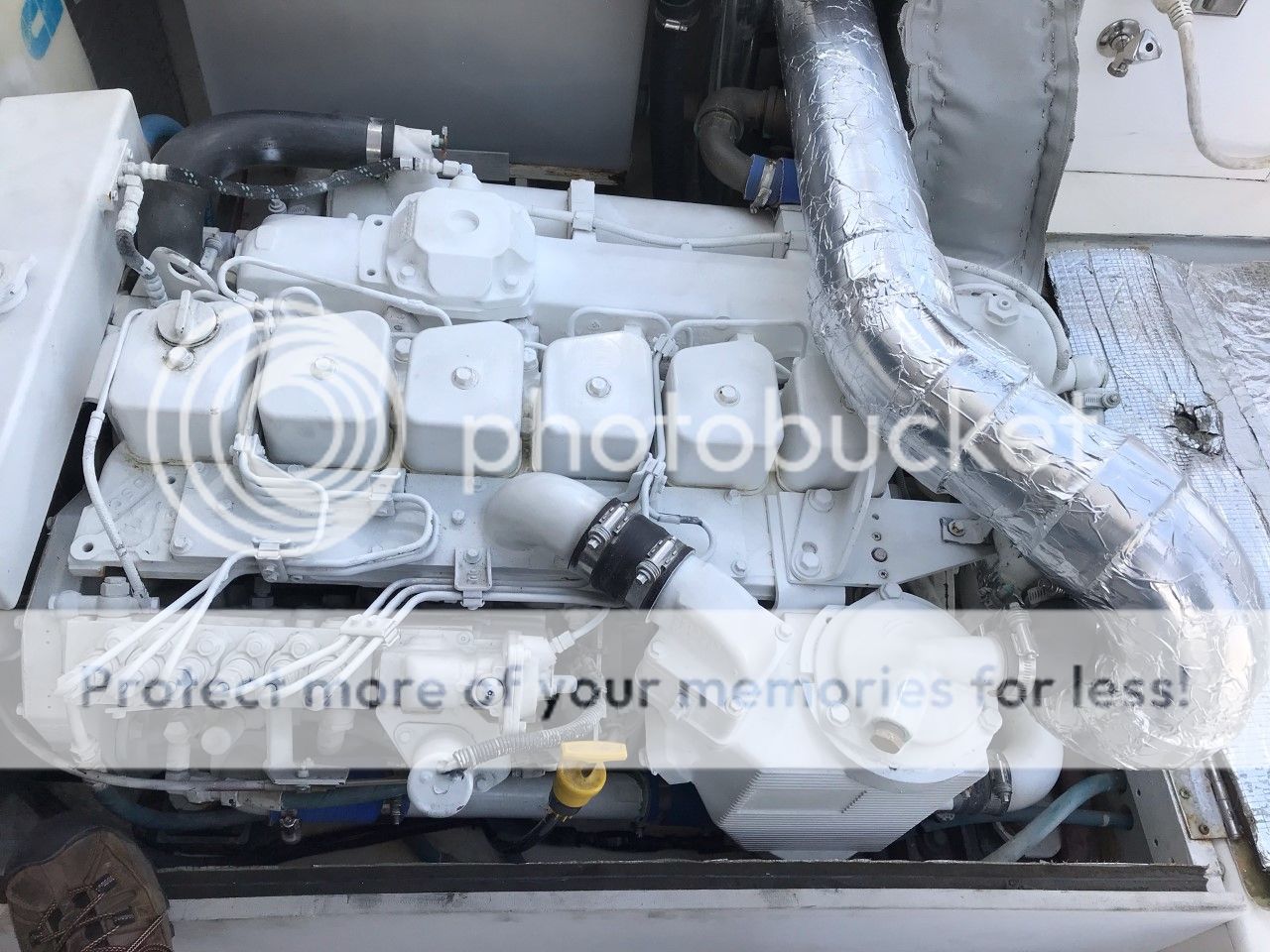

port side before cold air induction installation,90 degrees ,straight pipe,90 degrees, in hot pipe than sprinkler head in 5" SS than 70 degrees fitting, blue silicon and muffler.

capt.bob lico

bero13010473

bero13010473

Re: Exhaust size from Turbo??

Bob,

Your design is optimum and had my sights on doing that, but using larger mufflers going down the shaft alley.

My problem comes in that I cannot take the required measurements to make and fit till deck is back in, till motor boxes are on.

Right now I am trying to get time to fit up the struts I'm making, get motors in place to bolt down then see if I can modify shaft log to fit new location angle to accommodate 1-1/2" shafts from the 1-1/4" I had.

I did manage to get shafts way down low for an 11deg shaft angle. 210 hp is not really worth the extra effort of reduced angle and 1-1/2" shafts...but down the road I like the option of being able to up the power. I'd swap up, my motors would need too much and wrong blocks to modify...but everything else would be ready.

Anyway, where I am I need to get exhaust dealt with in the state it is in...it needs to go under deck and for that reason I will use surge tubes and those God ugly flaps on the transom flanges for a little extra protection. I also have large mufflers that are baffled. All in all it should be more then adequate according to Captain Patrick's builds.

I will need to redo the exhaust elbows real soon...the ones I have will get me going, but not happy with condition they are in. My hope is to get all up and running ASAP as in this season as mechanic helping me leaves in 3 weeks for Florida..permanently. I really want boat in water and running so he can workout any issues before he goes. Diesel is not what I am familiar with at all...so in and running is where I need to be.

Your design is optimum and had my sights on doing that, but using larger mufflers going down the shaft alley.

My problem comes in that I cannot take the required measurements to make and fit till deck is back in, till motor boxes are on.

Right now I am trying to get time to fit up the struts I'm making, get motors in place to bolt down then see if I can modify shaft log to fit new location angle to accommodate 1-1/2" shafts from the 1-1/4" I had.

I did manage to get shafts way down low for an 11deg shaft angle. 210 hp is not really worth the extra effort of reduced angle and 1-1/2" shafts...but down the road I like the option of being able to up the power. I'd swap up, my motors would need too much and wrong blocks to modify...but everything else would be ready.

Anyway, where I am I need to get exhaust dealt with in the state it is in...it needs to go under deck and for that reason I will use surge tubes and those God ugly flaps on the transom flanges for a little extra protection. I also have large mufflers that are baffled. All in all it should be more then adequate according to Captain Patrick's builds.

I will need to redo the exhaust elbows real soon...the ones I have will get me going, but not happy with condition they are in. My hope is to get all up and running ASAP as in this season as mechanic helping me leaves in 3 weeks for Florida..permanently. I really want boat in water and running so he can workout any issues before he goes. Diesel is not what I am familiar with at all...so in and running is where I need to be.

Re: Exhaust size from Turbo??

the real deal was (no names ) Cummins northeast representative had heard about my boat from cummins techs on long island and then witness the boat running offshore at 30 knots. he contacted me and i allowed the two techs to board with instrumatation. friendly people and were litterally stuned with both zero warranty work,zero repairs in 13 years and incredible performace but that is a muti issue because of installation inovation more then engine performace enhancements. they love it when i told them you guys are special because i have never allowed a marine mechanic on this boat in the 20 years i have owned it.and yes i am a stock holder thank you .

capt.bob lico

bero13010473

bero13010473

Who is online

Users browsing this forum: Bing [Bot], Google [Bot] and 41 guests