new member saying hello and quick question on pvc board

Moderators: CaptPatrick, mike ohlstein, Bruce

new member saying hello and quick question on pvc board

Hi..

This is my first post. Just wanted to say hello from the Caribbean (Trinidad) and to let you guys know how much I have learnt from this site. I have a quick question and did not see anything on this before. I am thinking of using 3/4" PVC board for my flooring. I saw a post earlier on the heat issue for use on an engine box but what about the flooring? Will it warp? It currently has Marine ply with a thin fiberglass sheet on top and below but the edges was not sealed properly and the stringers were not sealed so are also rotten. I was thinking of using PVC for the support and floor. I know it's not the best option but is this ok or not recommended. I was looking at the ease of installation and budget as I think it's something I can do myself quite easily.

Thanks in advance for your advice.

Roger

This is my first post. Just wanted to say hello from the Caribbean (Trinidad) and to let you guys know how much I have learnt from this site. I have a quick question and did not see anything on this before. I am thinking of using 3/4" PVC board for my flooring. I saw a post earlier on the heat issue for use on an engine box but what about the flooring? Will it warp? It currently has Marine ply with a thin fiberglass sheet on top and below but the edges was not sealed properly and the stringers were not sealed so are also rotten. I was thinking of using PVC for the support and floor. I know it's not the best option but is this ok or not recommended. I was looking at the ease of installation and budget as I think it's something I can do myself quite easily.

Thanks in advance for your advice.

Roger

-

Whaler1777

- Senior Member

- Posts: 649

- Joined: Sep 10th, '06, 19:43

- Location: NY

Re: new member saying hello and quick question on pvc board

No good... Too much flex...

'79 Bertram 31' Sedan

Re: new member saying hello and quick question on pvc board

Thanks...this is what some of the guys in the Yacht Club here told me when I mentioned what I was going to do....guess I will have to return the sheets...what is the recommended solution

-

Whaler1777

- Senior Member

- Posts: 649

- Joined: Sep 10th, '06, 19:43

- Location: NY

Re: new member saying hello and quick question on pvc board

Coosa board is a favorite if you want to DIY... If you want plug and play glass tech is the way to go

'79 Bertram 31' Sedan

Re: new member saying hello and quick question on pvc board

I use PVC board, both 3/8" and 3/4" thick, for lots of things, but definitely not for flooring or any other application that would be considered "structural".

Coosa board (or an equivalent) is the way to go. It is light, rigid and takes glue and paint well. I have heard it is not so nice to work with, due to the dust being nasty to breathe, hence everybody I know who has done much with it wears a dust mask. There are other rigid boards that also will be good for your application.. if there are any boatbuilders or repair shops near you, see if you can get some of what they use. They might have some extra you can buy, but if not they could tell you what is available locally, or at least where they get whatever they use.

Coosa board (or an equivalent) is the way to go. It is light, rigid and takes glue and paint well. I have heard it is not so nice to work with, due to the dust being nasty to breathe, hence everybody I know who has done much with it wears a dust mask. There are other rigid boards that also will be good for your application.. if there are any boatbuilders or repair shops near you, see if you can get some of what they use. They might have some extra you can buy, but if not they could tell you what is available locally, or at least where they get whatever they use.

Frank B

1983 Bertram 33 FBC "Phoenix"

--------------

Trump lied! Washington DC isn't a swamp.. it is a cesspool!

1983 Bertram 33 FBC "Phoenix"

--------------

Trump lied! Washington DC isn't a swamp.. it is a cesspool!

Re: new member saying hello and quick question on pvc board

Thanks again...I plan to patch for now so that I can use the boat...I will make a template and get one of the boat repair places to make a flooring for me in the meantime...Think I will leave the floor to the professionals....there are many more DIY projects required on the boat for me to tackle

Re: new member saying hello and quick question on pvc board

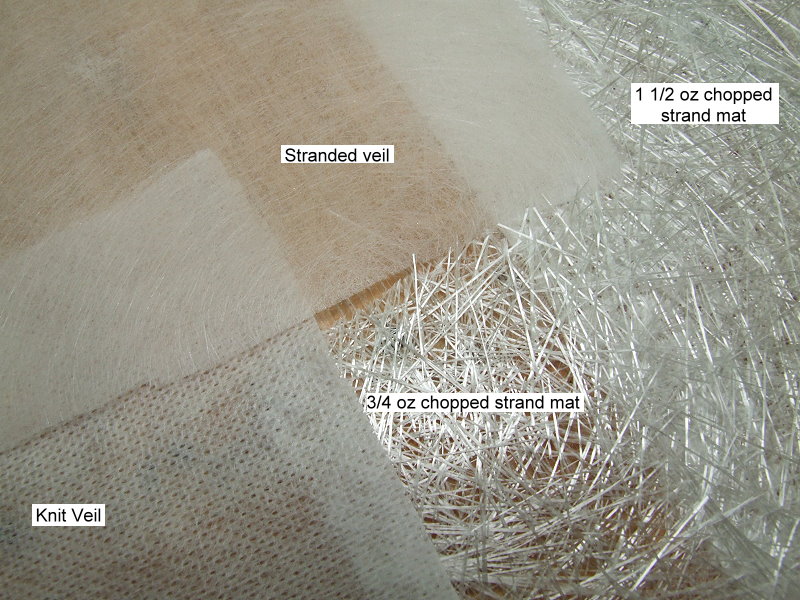

i will go with whaler and IR guy .pvc board to much flex and wear factor,not really made to walk on.IR guy terrible itchy for 5 minutes cutting coosa- 26 with tee shirt on not a good idea. use 26 in 3/4"then lay up two layers of biax on bottom and one layer on top follow by veil.i will show photo of coosa cockpit with maximum size hatches.

Last edited by bob lico on May 25th, '15, 10:43, edited 1 time in total.

capt.bob lico

bero13010473

bero13010473

Re: new member saying hello and quick question on pvc board

this is had i did it ,very carefully cut hatches out with 1/8" router bit and you will have perfect hatch already done no waste.

capt.bob lico

bero13010473

bero13010473

Re: new member saying hello and quick question on pvc board

capt.bob lico

bero13010473

bero13010473

Re: new member saying hello and quick question on pvc board

capt.bob lico

bero13010473

bero13010473

Re: new member saying hello and quick question on pvc board

BOB...

It was great talking with you the other day.. but I hate to see a B38 just deteriorating like the one we spoke of.

Looking at your pictures.. two beers and two coffees.. who ever works on a boat and drinks coffee?

It was great talking with you the other day.. but I hate to see a B38 just deteriorating like the one we spoke of.

Looking at your pictures.. two beers and two coffees.. who ever works on a boat and drinks coffee?

Frank B

1983 Bertram 33 FBC "Phoenix"

--------------

Trump lied! Washington DC isn't a swamp.. it is a cesspool!

1983 Bertram 33 FBC "Phoenix"

--------------

Trump lied! Washington DC isn't a swamp.. it is a cesspool!

Re: new member saying hello and quick question on pvc board

Thanks for the advice and pictures Bob...the floor looks great...what is vail? is that like a non-skid layer? ...I was also wondering about the coffee..I agree with IR guy...who drinks coffee working on a boat??

Re: new member saying hello and quick question on pvc board

lets put f/g material in descending order from thick to thin ; woven roven,biax,cloth,mat,and veil which looks like a bride`s wedding dress.my son drink`s beer and i drink coffee when i have to create.

Last edited by bob lico on May 25th, '15, 10:43, edited 1 time in total.

capt.bob lico

bero13010473

bero13010473

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

Re: new member saying hello and quick question on pvc board

captain a photo is worth a thousand words.-----------perfect photo

capt.bob lico

bero13010473

bero13010473

Re: new member saying hello and quick question on pvc board

i should mention the center section has a 3/8" half lap routed the entire length and lays flat with lap joint directly over deck supports (1" x 8") and SS 3" screwed every 6" .there is a 2' x 3' titanium plate under chair and this chair backing plate would be useless unless the center section is strong like bull.center section is also ribbed underneath every two foot.port and starboard section are tilted to outside a few degrees for water runoff.and are only glue down with 3m 4000 and can be lifted if needed.there is another 1" x8" support to give rigidity to port and starboard sections.then i have a 4" keyway cut into these sections to prevent movement fore and aft (no screws) this 4" section is pvc and sit 1/4" lower as runway for water leading to 16" scupper cutout and out scuppers.cockpit sole is as strong as a dance floor and supports 14 people at high speed.

capt.bob lico

bero13010473

bero13010473

Re: new member saying hello and quick question on pvc board

Bob, the deck on our '31 is almost toast and I'd like to follow in your footsteps. Your deck looks perfect and I'm jealous. I have questions about your install that I was hoping you or the other members could help me with. I'm a pretty capable woodworking guy but not a fiberglasser, so I'm quite hesitant to do anymore fiber glassing than necessary. It looks like from your post and others that Coosa Board is the magic stuff, and CaptPatrick's excellent lesson (deck support) on FRP has me fairly confident my skills will transfer. However, the boat is in the Bahamas and a real pain to get something in a pinch so bringing it with me and having a clear plan is the only way to go. The preference in the Bahamas is quick fix and worry later which means plywood and I'd like to go permanent which likely means doing it myself. It sounds like a fun/challenging project but I'm not sure if up to the non-traditional woodworking piece. Can you or anyone else consider these questions?

1. I was hoping to use 3/4" or 1" thick Coosa for the deck and then just paint it, but then I re-read your post. Did you use additional layers of Biax for strength or appearance or both? I don't trust my fiberglass skills and would go to a thicker deck material if it was a strength issue.

2. Does Coosa machine similar to wood (besides the whole dust/ich thing)? Saws, routers? Can you use 2 part epoxy to join FRP tubing/coosa board similar to what wood glue does for wood?

3. The rabbits for the hatches, did you machine a separate piece with smaller inside dimensions and laminate to the deck or is there enough material in the original deck to allow for the rabbit?

4. Was your deck support system similar to how CaptPatrick outlines in "deck support"?

4. Am I kidding myself and should just try and nurse her back to the states? I'd like to try but don't want it to be a train wreck either.

Thanks folks.

1. I was hoping to use 3/4" or 1" thick Coosa for the deck and then just paint it, but then I re-read your post. Did you use additional layers of Biax for strength or appearance or both? I don't trust my fiberglass skills and would go to a thicker deck material if it was a strength issue.

2. Does Coosa machine similar to wood (besides the whole dust/ich thing)? Saws, routers? Can you use 2 part epoxy to join FRP tubing/coosa board similar to what wood glue does for wood?

3. The rabbits for the hatches, did you machine a separate piece with smaller inside dimensions and laminate to the deck or is there enough material in the original deck to allow for the rabbit?

4. Was your deck support system similar to how CaptPatrick outlines in "deck support"?

4. Am I kidding myself and should just try and nurse her back to the states? I'd like to try but don't want it to be a train wreck either.

Thanks folks.

-

Tony Meola

- Senior Member

- Posts: 7036

- Joined: Jun 29th, '06, 21:24

- Location: Hillsdale, New Jersey

- Contact:

Re: new member saying hello and quick question on pvc board

If getting Coosa, Dyvinicell or one of the other products that is similar is too hard or too expensive, you can still use play wood. Makes a heavy deck, too heavy as you get to be older like some of us but solid.

you need to use 3/4 outdoor or marine ply. Outdoor will work. You need to take epoxy and thin 10% with alcohol. Then coat the wood really good, all sides and edges. It needs to soak in. Then you would coat all sides and edges with glass mat, following the same order as Bob described.

If you do it right, you are probably good for 20 years.

But Coosa right now as far as we know is final.

If you put diesels in the boat and rebuild the strut pads, you will be adding weight to the stern and with the plywood deck, the stern will be sitting low in the water. Not an issue unless you cover the exhaust.

you need to use 3/4 outdoor or marine ply. Outdoor will work. You need to take epoxy and thin 10% with alcohol. Then coat the wood really good, all sides and edges. It needs to soak in. Then you would coat all sides and edges with glass mat, following the same order as Bob described.

If you do it right, you are probably good for 20 years.

But Coosa right now as far as we know is final.

If you put diesels in the boat and rebuild the strut pads, you will be adding weight to the stern and with the plywood deck, the stern will be sitting low in the water. Not an issue unless you cover the exhaust.

1975 FBC BERG1467-315

Re: new member saying hello and quick question on pvc board

Thanks Tony; those are helpful suggestions.

M.

M.

Re: new member saying hello and quick question on pvc board

combackid wrote:Thanks Tony; those are helpful suggestions.

M.

20 years is permanent enough in my mind for a boat. Marine Plywood is real easy to get and work with. I had mine covered with nautilex...2 day job in all.

Down side is I helped prior owner do his deck 12 years before I bought boat from him...then after a few years had soft spots so I in turn went with running takeout glass deck from a rebuild...touched up and done.

Coosa would be real nice for those projects you need to pull deck and light on hands...

Re: new member saying hello and quick question on pvc board

I'd have to ship it in either way given our remote location, so I guess I'd prefer to use Coosa if it were to last longer (downside of machining fiberglass not withstanding). Do I still have to glass over the Coosa or can I just topcoat with non-slip epoxy paint?

Re: new member saying hello and quick question on pvc board

3/4 " coosa 26 will still require a F/G layer if you intend to drop a 496 pound bluefin tuna from gin pole however if you are using as a cocktail boat and entertainment is your mai priority then forget bottom biax buildup but you will need to cover coosa 26 with at least f/g cloth and resin to make make smooth so you can paint. you really cannot fill in holes and craters in coosa with just resin coat.

capt.bob lico

bero13010473

bero13010473

Re: new member saying hello and quick question on pvc board

Bummer. Thanks Bob, at least I know and can plan for it.

Thanks for your help gents.

Thanks for your help gents.

Who is online

Users browsing this forum: Bing [Bot] and 11 guests