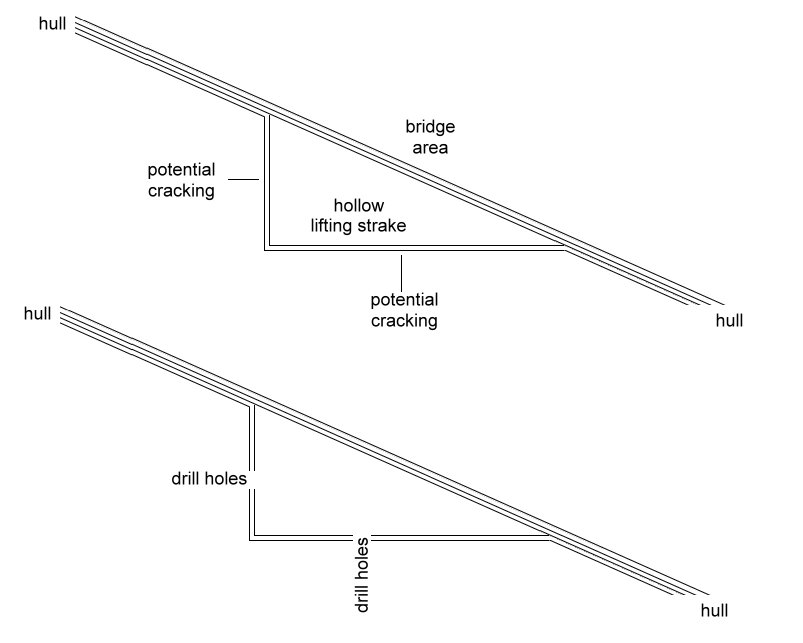

In the first pic you may see that on the LOWERMOST strake (not the middle one) there are some white marks. This is salt, in FINE powder form, that came out of a minute crack as I finger tapped the area. The crack runs the upper corner of the strake (where the strake meets the hull), for about 60 cm / 2 feet.

The same area after some chisel work. You can see that the rain water created some vertical salt marks.

After some more chiseling, there seems to be an interrupted fine mat layer (over the strake, hull side) and some brown (wood?) on strake surface, under all gel and anti foul.

What does this all mean?

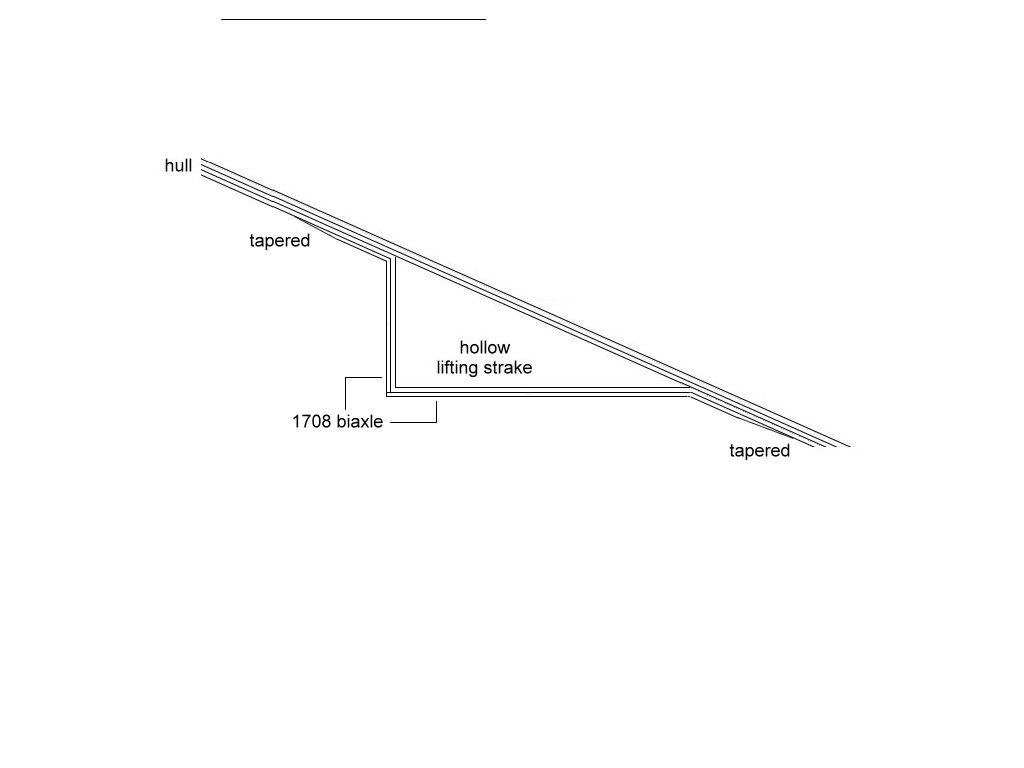

1. Is the strake shape part of the hull shape and therefore the boat is cracked?

2. Is the strake an addition to the hull and, as such, glassing it or epoxying it would suffice?

I don't remember having witnessed water in the bilge last summer, BUT, some little water in the bilge under the cabin sole I explained to be rubber water tank leakage which was put under there. Had there been a crack to the boat the water should have been considerably more, no?

Can somebody please gimme some advice as to where to start from? Thanx.