Page 1 of 1

Fuel Tank problem

Posted: Oct 16th, '09, 13:43

by scenarioL113

I pulled the plate out that has the sending unit attached to it, I am fitting my return lines into it.

I noticed the fuel in there is greenish in color, it is OLD GASOLINE. The gasoline in there is PRE-ETHANOL.

I have noticed the gel-coat on the inside of the tank is peeling off all over the place.

I am converting to diesel and am planning on using this fuel tank. I am going to empty the tank and scrape as much of the gelcoat peels off as I can and vaccuum it out.

Is this not going to work?

Posted: Oct 16th, '09, 14:05

by Brewster Minton

no there are baffels in the tank so you will have to pull the whole top off. I am afraid you are screwwed but I may be wrong

Posted: Oct 16th, '09, 14:39

by scenarioL113

I am in agreement that things are bad!

Very disgusted to say the least. I guess I will have to fabricate a new one myself. Prob Stainless Steel.

Posted: Oct 16th, '09, 15:12

by In Memory Walter K

Wait till you hear from Captain Patrick. I am pretty sure you can have the tank cleaned and flushed out for use with diesel. The baffles aren't gel coated (I think). I hope you can use it. Walter

Posted: Oct 16th, '09, 16:02

by Brewster Minton

Walter I think the baffels are just in the way and would keep you from getting all thought the tank.

Posted: Oct 16th, '09, 20:51

by John F.

I have a 170 gallon or so fuel tank out of my 1969 B31 gasser that's never seen ethanol. If you're interested, we can work something and 100% will go to Capt Pat.

John F.

Just noticed you have a 28--sorry, don't know if it'll fit.

Posted: Oct 16th, '09, 22:16

by CaptPatrick

Frank,

The gelcoat in tanks are the main defense against liquid being absorbed into the fiberglass. Yes, fiberglass is porous... Once liquid or even moisture gets past the gelcoat and penetrated the glass it's pretty much game over. However, on the brighter side, this doesn't happen quickly.

Depending on how bad your tank is and whether or not the gasoline has already started to be absorbed, you may be already too far gone or you may be able to use diesel for several years before it gets critical.

If you were keeping it a gas boat, then I would only say to dump the tank and replace it. Diesel isn't nearly as dangerous as gas, so you could play the odds and go ahead and use the tank, after cleaning it out as best as possible.

If you choose this route, just monitor the tank closely, always be on the lookout for even the slightest amount of fuel in your bilges, and be ready to replace the tank on short notice. Pay close attention to your fuel filters. Once it starts leaking, it all over but the shouting.

Now, if were my boat, I would bite the bullet and go for a new tank...

Br,

Patrick

Posted: Oct 17th, '09, 08:23

by scenarioL113

Is there anyone out there that can re-line the tank with some sort of barrier resin or something along those lines.

I figured if I removed the tank and cut the top off it could be cleaned of all gelcoat (which will come off VERY easily in this case). Then the inside could be coated with something that would seal the fiberglass in place of the gelcoat.

The top of the tank could then be re-glassed in place. I have no leaks as of this time, the tank has about 8 inches of old crappy fuel in it.

For the life of me I have no idea this happened. I have had this boat in drydock since BEFORE the ethanol was put in place. I wonder if New York was using an ethanol blend BEFORE everyone else. That is the only thing I can think of.

If this route is not feasible, I will fabricate a new tank myself out of 316L Stainless steel. I can weld pretty good and my father even though retired is a great welder.

Never did a fuel tank before but would just copy the existing tank exactly, inside and out.

What gauge or thickness for stainless steel, anyone have one? 3/16"?

Posted: Oct 17th, '09, 08:57

by CaptPatrick

Frank,

In the past, we've had a lot of discussion about lining tanks, under the ethanol topic. Bottom line is that your fiberglass is already impregnated with fuel and other sludge. Nothing is going to stick it and any coating will likely end up peeling off just like the old gelcoat...

3/16" will be fine for thickness. Hope you're saying you can TIG weld. Lay out your weldaments in such a manner that you you fuse all exterior welds, rather than using filler material. Make bends where ever possible and keep your welded seams to the fewest possible.

Br,

Patrick

Posted: Oct 17th, '09, 09:34

by Ed Curry

You should give Rob at Raybo a call. He can give you the pros and cons on relining.

Removing the original tank is the hardest part of tank replacement on the 28

so I went with aluminum figuring the deck comes up easy enough and if I get 15 years at of it I'll replace it again and still be ahead of the game.

Posted: Oct 17th, '09, 09:40

by Carl

New York has been using Ethanol for years in the Winter Blend, remember the Oxygenated Gas Stickers that would show up on the Gas pumps each year as Winter came on. The car which was running real well would cough and sputter for a bit when you cranked it up, lost that spunk as your MPG dropped. Well that was Ethanol.

This is only my opinion-

Marina's don't sell much fuel at the end of the year so I don't think they where taking full tanks of this ethanol blended fuel on, so the % of ethanol would have been less. Now if you where only topping the tank a bit at the end of the season the % of ethanol dropped even further so nobody really felt the full effects of the 10% Ethanol till it was mandatory year round.

Guess your lucky like me...you either got a good dose of the Corn Juice or just had enough to do a number on your tank over time.

Sr had Ethanol in his fiberglass tank. He just stated having problems when he found a deal on Diesels and swapped over. At that time we did not know the fuel was compromising the tank, so he didn't think much about the fact when he cleaned the tank he was pulling chunks of gel coat and fiberglass from the tank. Also the first year he had to polish the fuel constantly as he was getting lots of debris in the fuel. By the time I found out the ethanol was eating my tank his problem cleared up for the most part. That was a good 5 years ago...so his tank has held up. And that is a Hatteras tank...not even a Bertram tank.

Me, I'd change the tank...its just not worth worrying about getting stuck with a hundred gallons of fuel in the bottom of the boat.

If you go 316SS, 3/16" is way too thick. I would also opt for 316L and 316L filler. I'd also consider using a back flux.

Posted: Oct 17th, '09, 10:23

by In Memory Walter K

Patrick-Given your comment that fiberglass is porous and that gelcoat is the barrier that protects it, what about our bilges? I don't think they're gelcoated and there's some degree of water down there all season. Walter

Posted: Oct 17th, '09, 10:36

by CaptPatrick

Walt,

Bertram, as with most boat manufactures, followed up the final layup with a sealer coat of resin which effectively does the same job as a gelcoat would do. However, you may notice areas in the glass where it's starting to look white instead of green. These are areas that should be re-sealed, preferably with epoxy. For the most part, only the center bilge ever holds any significant water and since the bilges are open and can breathe, there's no real worry about water intrusion like there is below the water line or in a tank holding liquid.

Br,

Patrick

Posted: Oct 17th, '09, 21:02

by scenarioL113

If tank is going to be constructed from Stainless Steel can anybody recommend what gauge or thickness the stainless should be?

Posted: Oct 19th, '09, 07:00

by scenarioL113

Anyone use a polyethylene tank???

Posted: Oct 26th, '09, 17:34

by scenarioL113

I pulled the cockpit deck off today, not too bad but heavy for 1 guy to do alone.

I cut the sides and rear areas where the tank is glassed into place. I cant break the bottom resin blob that is on the bottom.

I cannot for the life of me pull the tank from the hull! I set-up 2 4x4's across the cockpit and a floor jack with heavy duty strapping and lifting the tank by the two glassed loops.

I broke one of the 4x4's in half, I figure I had well ovewr 1000lbs of force.

I set it up again and put a bunch of force on it and tried prying with a long crow-bar near the rear and front of the tank "intimidating" it but still did not work.

I am contemplating cutting it out with the saw-zall but figured if someone had a better idea I am all ears.

I am replacing it with a polyethylene tank that will have different dimension than the factory one but will easily fit into the area. Unfortunately the replacement will only be 157 gallons but it is close to what was in there. I figure I will still have decent range in there with the 4BT's.

That poly tank is all set-up with the fittings right where the rear center hatch will be and has 4 extra 1/2" plugs for the return lines.

Posted: Oct 26th, '09, 18:33

by Ed Curry

The key for my removal was to twist and not just pull it out. I was trying for two days to pull from one corner of the tank hoping to peel it off the bottom. when I put a 6' steel bar between the tank and the rudder shelf I felt the tank go sideways with a loud pop and the damn thing was out. Don't pry it up, pry it sideways.

Good luck.

Posted: Oct 26th, '09, 18:42

by scenarioL113

Thats what I been doing, prying against the rudder box down there near the stringer.

Of course, I am being cautious as I am being brutish.

I am starting to see how diesel conversions can cost $30,000 just in labor costs....jeeez! I have a broken coolie!

Posted: Oct 26th, '09, 18:50

by CaptPatrick

Frank,

Correct me if I'm wrong, but I'm assuming that you've already drained the old fuel out of the tank... However, those remaining fumes are still explosive and using any electrical tools can be dangerous.

I cut out Gerry Santiago's tank with an electric saws-all, fitted with a carborundum grit blade. Gone in about an hour. Don't use a toothed blade, it can create sparks while cutting fiberglass and the teeth won't last 3 minutes.

To make the job as safe as possible, I set a large diameter floor fan to blow any fumes out and over the transom. I also used my Blue Blower, rigged with dryer hose to force air into the tank from the forward fill manifold & out the aft supply manifold. I let these two fans run for about five minutes before beginning to saw at the forward end, (big fan close behind me).

Once the top was mostly off, I partially filled the tank with water and about a half a jug of liquid detergent. Using an old scrub brush I scoured any remaining old fuel into emulsion, and pumped out the water before continuing the cutting.

Be careful...

Be,

Patrick

Posted: Oct 26th, '09, 19:50

by scenarioL113

Thanks Capt!

I got most of the fuel out, I have NOT started to dismantle the tank itself.

I have about 1 inch of fuel left as of now.

I am hoping the tank will break loose from the glob of resin holding it in. I dont know if I missed anything else that may be holding it in place. I cut along each side, and then I cut from the bottom to the top and then across the top of the front of the tank. All of the cuts I made are continuous.

Is there any straps or something else I may have missed.

I do not have access to any heavy equipment, too bad I had a gantry setup but do not have it any more (it was borrowed) and it was setup with a 2 ton chain hoist.

I will heed the warning about blowing myself up. The gas is very old and may not even be flammable anymore.....????

I dont know but I am a little frustrated. The tank being trash was VERY unexpected. I had not put fuel in since 2005 or earlier.

Posted: Oct 26th, '09, 20:13

by CaptPatrick

The gas is very old and may not even be flammable anymore

Treat it like it's fresh and highly volatile... Have you tried a few whops with a sledge hammer?

Posted: Oct 26th, '09, 20:18

by JP Dalik

Water, detergent and more water maybe a mix and a drain then more water and more detergent and a fan.

I hate working around old gasoline tanks. P U,,,,,,,, with a nice buzz and a 12 hour headache.

Posted: Oct 26th, '09, 20:25

by scenarioL113

Ya I did try the sledge hammer.

Usually after a day or so and a little rest (physically and mentally) I should be able to tackle the problem and maybe pry it somewhere and get a lil better leverage than I got today.

I will post some pics and keep you guys updated.

Hopefully I will get it soon.

Posted: Oct 27th, '09, 08:17

by Bruce

I am starting to see how diesel conversions can cost $30,000 just in labor costs

Thankyou for understanding. Most do not.

I've pulled two 31 tanks out. After cutting the tabing, both pried out relativly easy with a large wrecking bar under the front and back. Of course both the front and rear bulkheads had been cut out because they were being replaced.

Bondo to the hull just pried up.

Posted: Oct 27th, '09, 08:41

by Carl

scenarioL113 wrote:

I will heed the warning about blowing myself up. The gas is very old and may not even be flammable anymore.....????

The prior owner of my boat told me he emptied and closed off the Aux tank when he bought the boat, 12 years before I bought it. He did that to keep weight down... I had the boat a good 4- 5 years before I thought I'd clean up the tank and use it. Low and behold the tank was full of fuel. Had to be 12-17 years old.

Anyway I drained it into a drum and brought home figuring I'd have it taken away when I got the chnace. I set it down next to the garage and my wife started getting all pissy about it blowing up, catching fire Yadda Yadda Yadda... I told her it was so old it wouldn't even burn if I hit it with a flame thrower. She wouldn't back off so I grabbed a rag, dosed it with fuel and set it in a low bucket with some more fuel for good measure, then tossed a lit piece of cloth at it...FireBall with the blackest damm smoke I've ever seen. With that I put the drum back onto the truck moved the truck away from the house and garage and disposed of it the next day.

Old fuel still burns like a bastard, just don't tell my wife I said that....

Carl

Posted: Oct 27th, '09, 08:53

by alano

FWIW, I cut several different size wedges out of 2x6, 2x4 and 2x8 and drove them under the tank after cutting the tabbing and it popped up eventually, don't know if you have room to swing a maul, I have a 35 w/out the generator so that wasn't issue. br, Alan.

Posted: Oct 27th, '09, 09:55

by Skipper Dick

Frank,

When I got ready to replace my 190 gallon tank, I siphoned all the gas I could get out from the tube, then pulled the tube to get acces to the remainder with the siphon hose. I got all but about a cup that remianed then I tied a rag on a wood pole and sponged the rest out until there was no more than a spoon full. I left the tank open and it evaporated. Then I ran water and soap in the tank and sprayed it around as much as I could until all but a little fume was left. After siphonbing out the water and letting it dry for a couple of days, there was little or no fumes.

Once I got the tabs cut and was down to the tank being held in place by the goop they put on the bottom, I backed the boat up under my lift and ran a tow chain into the tube access hole with a hook on the end. With the other end on the lift, I raised the lift until the tank finally gave way. I thought I was going to lift the whole stern of the boat, but it gave finally after I got on top of the tank and jumped up and down a little.

The rest was easy.

Dick

Posted: Oct 27th, '09, 12:19

by Ed Curry

I have a couple of 4x6 and 6x6 that I use as a gantry for removing my engines. You're welcome to borrow them and a 6' wrecking bar if you think that will help.

Posted: Oct 27th, '09, 16:13

by Charlie

George Dent removed the top of a 25B tank some years ago. All the gelcoat was peeling. He ground her down and coated with West System. Then he fiberglassed the top back on. All went well until ethanol. It attacked the top and even started to attack the West epoxy. The West did stick very well to a 45 year old tank.

Posted: Oct 27th, '09, 17:04

by scenarioL113

Thanks for all the replies!

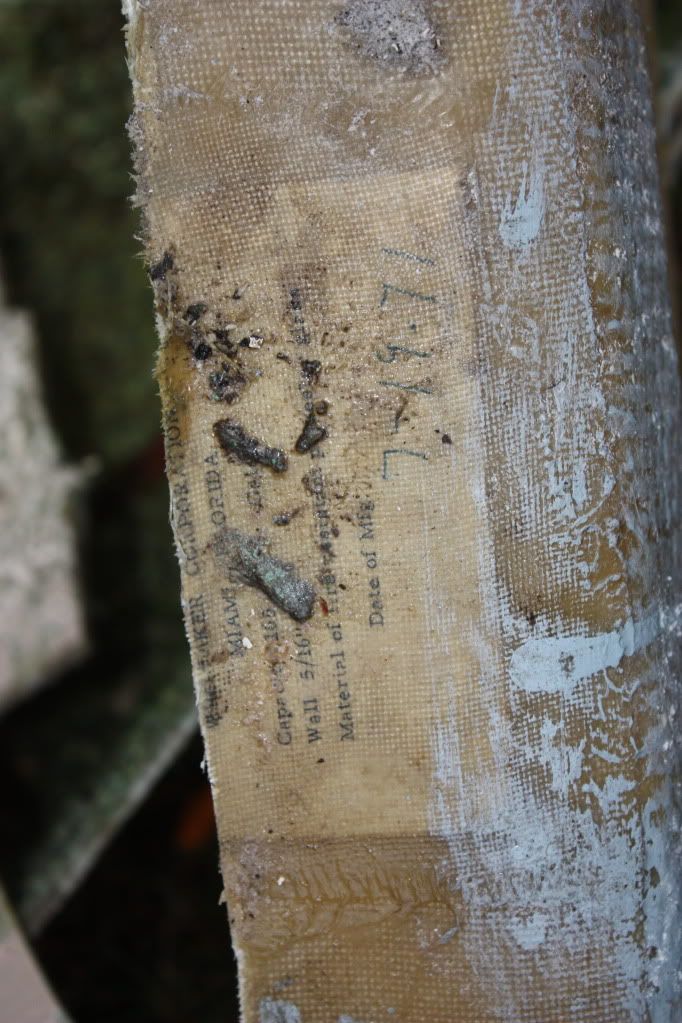

The tank is out and I have some very GRAPHIC pictures of a Bertram tank that has been destroyed by ethanol and then destroyed by its owner to get it out.

The old fuel was VERY flammable, I had burned some in a container to see how explosive it may have been.

I had less than 1 inch of fuel and I filled tank with water to top, I then drilled a hole near the top on the side and let the water drain into bilge, when the water drained enough to start letting the fuel (fuel floats on top) pass I drained into a bucket. This worked out pretty well. After I got the fuel out I added detergent and made suds.

I then cut the top off and proceeded to cut working my way down cutting as I went.

I got it all out, it was gooped on both sides of tank and the total length.

Posted: Oct 27th, '09, 17:25

by scenarioL113

Posted: Oct 27th, '09, 17:33

by scenarioL113

The goop holding the bottom of the rank fought me till the very end, even when I had most of the tank cut off it. I had plenty of leverage with the 4ft crowbars. It took the plywood up with it.

I believe these old Bertrams were built by old timers that were afraid of fiberglass and resin and over-killed when they put them together.

Its good to know they are well built.

Posted: Oct 27th, '09, 18:14

by CaptPatrick

I believe these old Bertrams were built by old timers that were afraid of fiberglass and resin and over-killed when they put them together.

Nope....

They were built by a bunch of new to the industry guys and nobody really understood or appreciated the strength of fiberglass, being a relatively new material to the boat building industry at the time, and they

inadvertently over-killed em...

Be glad they didn't have epoxy back then, or you'd still be up on the boat with a hammer and chisel.

Sometimes rippin' old crap apart is good therapy...

Posted: Oct 27th, '09, 19:12

by coolair

rippin' crap apart is GREAT therapy!

Posted: Oct 28th, '09, 07:44

by Rawleigh

Wow, that tank really was toast!! Good work on getting it out. I like you draining approach!

Posted: Oct 28th, '09, 09:01

by John F.

That tank is something. My tank looked fine--no ethanol. Looking at yours makes me happy that I went to aluminum before ethanol. I'd hate to have gas from there running through my 454s. Good luck with the rest of it. Nice job.

John

Posted: Oct 28th, '09, 17:17

by Bruce

The West did stick very well to a 45 year old tank.

More than likely the West system created a liner instead, which in and of itself felt solid.

Once the gel coat is gone and the glass absorbes the fuel all the grinding in the world won't make it stick to that glass.

Once that tank was filled and flexed some, I'll bet dollars to donuts if they would have pulled that tank back out, cut the top off there would have been numerous places where the west system wasn't sticking.

At that point its only a matter of time before it leaks.

Posted: Oct 28th, '09, 21:37

by scenarioL113

My tank was not leaking but it was starting to break down. I had tree-sap type liquid all over my hands and boots that I had a lot of trouble getting off. This is the crap that they are talking about that covers the internal parts of your engine and basically will ruin them if not caught early enough.

That was resin and fiberglass that was breaking down. Nasty stuff and smelled awful.

I drill holes in the tank as I was draining it of water and it was very thin on the bottom of the tank.

[/img]

[/img]