Page 1 of 1

Solving a Problem

Posted: May 11th, '09, 10:04

by CaptPatrick

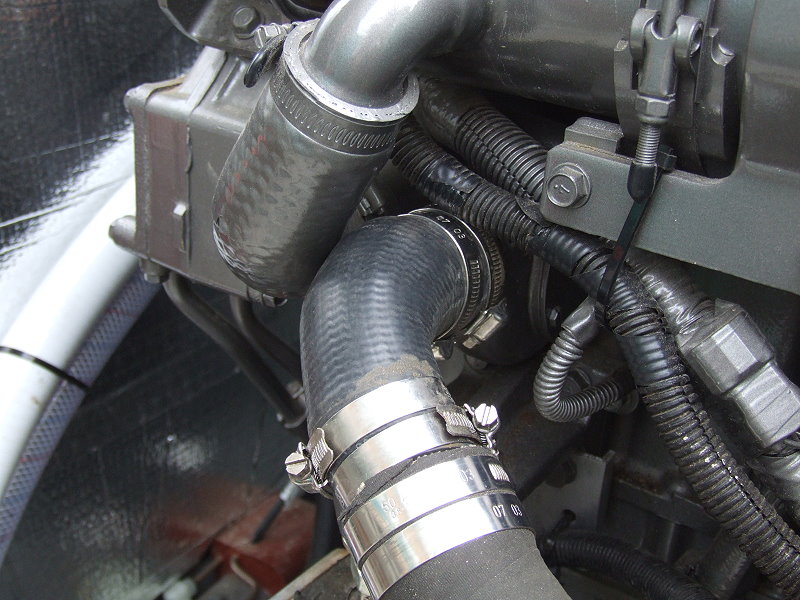

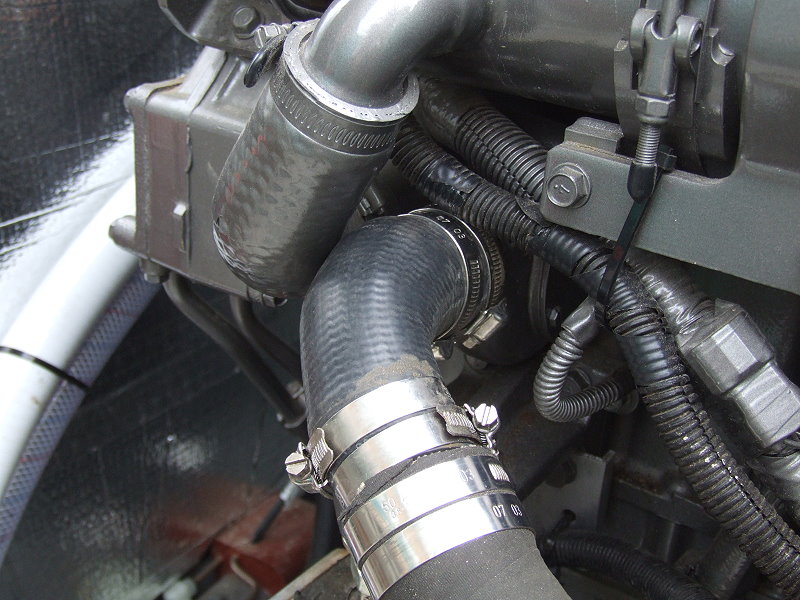

On this engine install, I needed a formed hose with a 90º bend at the raw water pump. The problem is that this piece of hose is on the suction side of the pump and the only pre-formed hose available was not wire reinforced to prevent collapsing.

After some thought as to how to overcome this problem, I decided to use AWAB hose clamps, which are 316 stainless steel, cut off the worm screw assembly, size the diameter to fit the hose and TIG fuse a pair for each of the two hoses.

The progression is now part of the

Tips Section and titled as

"Making Anti-Collapse Rings for Suction Hose"

Posted: May 11th, '09, 10:17

by Charlie J

as always nice job cap, thats the same hose that blew on me last year

Posted: May 11th, '09, 10:44

by CaptPatrick

Charlie,

In what way did it blow? Collapse, sprung a leak, hose clamps fail, ??

Posted: May 11th, '09, 10:47

by Rawleigh

Pat: Very interesting idea. Thinking outside the box again I see. Just out of curiosity, why not use hard pipe? I know you had a reason for doing what you did, but I want to learn.

Posted: May 11th, '09, 11:44

by CaptPatrick

Rawleigh,

Hard pipe would have been another joint of rubber hose, another 2 clamps and another fitting needing to be bonded. Plus visually cluttered.

My raw water supply is full flow 1 1/2" from the through hull and seacock. The full flow hardware required the use of 1 3/4" hard hose so I had to build an adaptor to mate the two hose sizes up. That was done with a 1 1/2" O.D. fiberglass tube to fit the bend hose, then sleeved with 1 1/2" sanitary hose to mate up to the 1 3/4" hard hose. 6 hose clamps in one 10" run was cluttered enough...

I originally tried a coil of 316 welding rod inserted in the bend, and it worked OK, but I just couldn't trust it. The clamp rings are 1/2" wide, half as thick as the wire, have less restriction to the water flow, are less likely to deform, and no way can they somehow get into the water pump.

Posted: May 11th, '09, 12:03

by Charlie J

back pressure, had to clean out all my exchangers last year before montauk, and replaced all originall hoses, 1600 hrs, it was a blow out, 2" rip

Posted: May 11th, '09, 12:09

by CaptPatrick

Thanks Charlie! I'll keep that in mind and pass it along to the owner...

Posted: May 11th, '09, 16:02

by Bruce

Carefull.

I've seen many seams on 316 anti crush rings come apart in less than a year due to weld contamination, even material corrosion without passivating in a saltwater flow application.

If you remember Pat, I used the same 90 hose style on Buddy Boy and we had no problem. If the inlet side is properly sized for the flow, the hose should not collapse.

Posted: May 11th, '09, 18:28

by CaptPatrick

Bruce wrote:Carefull.

I've seen many seams on 316 anti crush rings come apart in less than a year due to weld contamination, even material corrosion without passivating in a saltwater flow application.

If you remember Pat, I used the same 90 hose style on Buddy Boy and we had no problem. If the inlet side is properly sized for the flow, the hose should not collapse.

Gotcha' Brother!

Weld seams here shouldn't be an issue since the rings only support the hose itself and don't have any clamps or undue pressure on them. Even if the welds broke, the rings are still captured in the bend and won't move. They are fused overlaps & no filler metal used.

Just my usual overkill...