Right of passage ~ Serviced my aftercooler

Posted: Feb 7th, '23, 09:36

So I feel a sense of accomplishment, especially with everything that I read on line.

When I ran the boat up from the marina after delivery, the port engine got up to temp quickly and then leveled off. Figured I'd test the cooling system - Heat Exchanger would not hold pressure - replaced that. Then figured I'd work my way backwards.

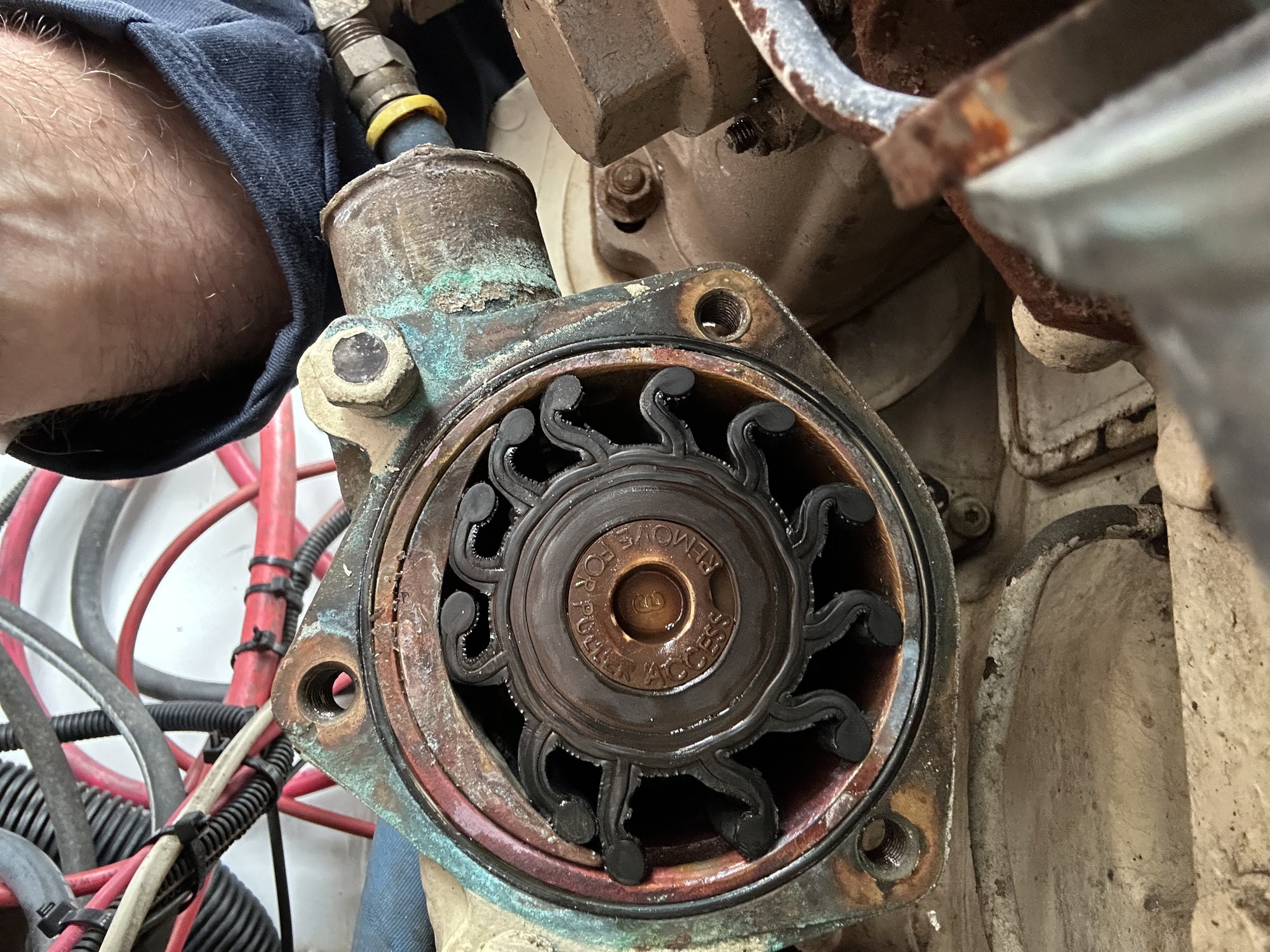

This is what I found - yep, that won't work very well

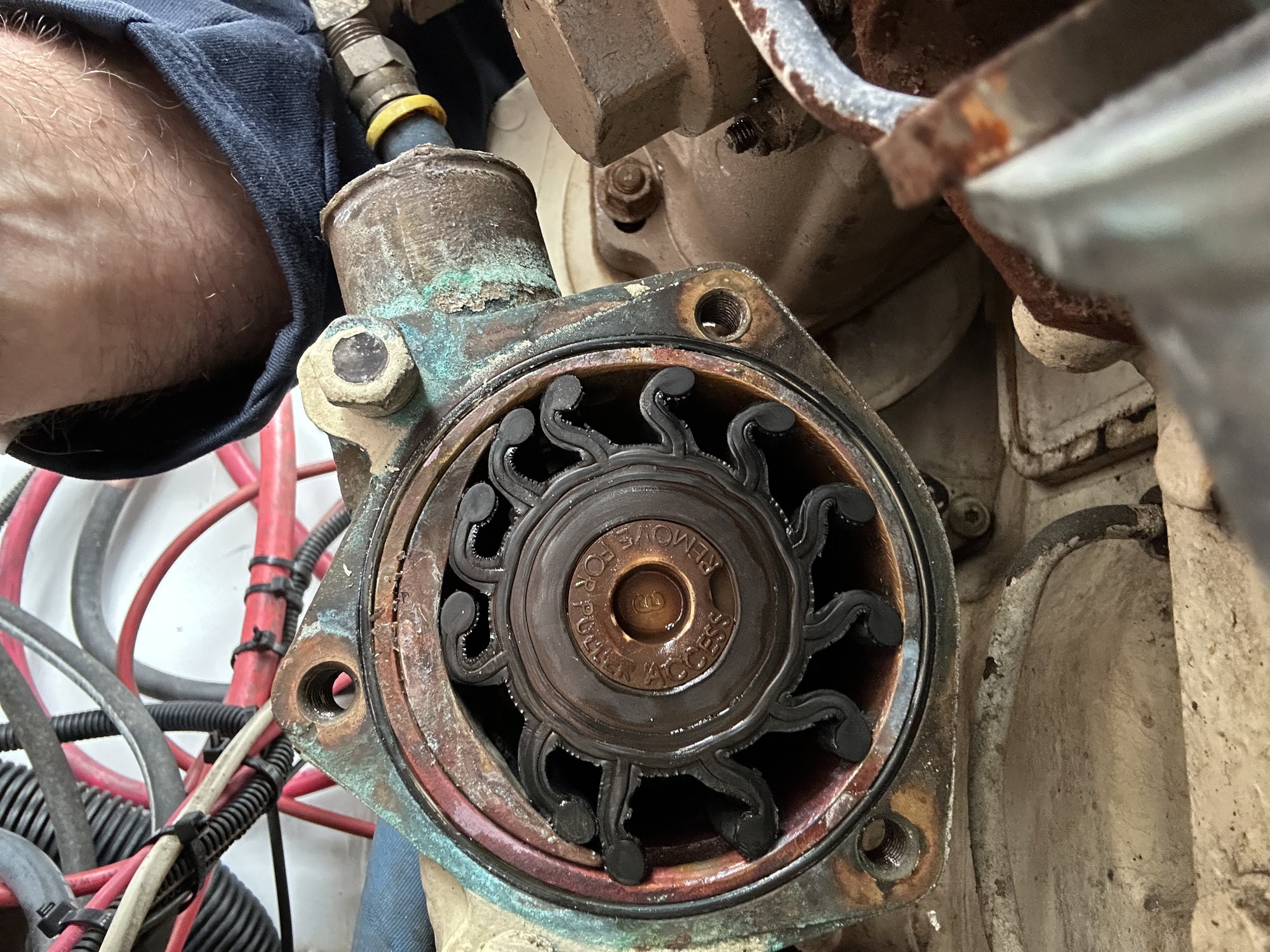

I had the previous marina change out the impeller, they never said if they found bits of it, In fact I think the description I got was that it needed changing, but wasn't bad...

So I decided to take a look

Really not bad - So wonder how long those bits have been in there.

Got the core out by heating the aftercooler on the BBQ grill then pouring water in the core to contract it. Cleaned in simple green and soaked for a few days. Used a fiberglass stake to remove the scale build up on the tubes.

Cleaned, sanded and painted everything

Got everything back together

Pressure tested! All good!

When I ran the boat up from the marina after delivery, the port engine got up to temp quickly and then leveled off. Figured I'd test the cooling system - Heat Exchanger would not hold pressure - replaced that. Then figured I'd work my way backwards.

This is what I found - yep, that won't work very well

I had the previous marina change out the impeller, they never said if they found bits of it, In fact I think the description I got was that it needed changing, but wasn't bad...

So I decided to take a look

Really not bad - So wonder how long those bits have been in there.

Got the core out by heating the aftercooler on the BBQ grill then pouring water in the core to contract it. Cleaned in simple green and soaked for a few days. Used a fiberglass stake to remove the scale build up on the tubes.

Cleaned, sanded and painted everything

Got everything back together

Pressure tested! All good!