Page 2 of 2

Re: repower

Posted: Nov 29th, '15, 20:17

by Stephan

bob lico wrote:terrible installation you better PM me before going on. why did you not go with ZF IRM 220A -----10 degree down angle!!!!!!!!!!!!!!!!!!!!

Jeez for a moment there I had my Lico translator off and misunderstood your message to be critical of my friend Tom and not your generous and experienced self offering to help....

I must be spending too much time on those other boat boards.

Best,

Stephan

Re: repower

Posted: Nov 29th, '15, 22:48

by bob lico

tom is my friend also thats why i am trying to help him.i been so busy lately i negleted to advise tom.

Re: repower

Posted: Nov 30th, '15, 15:53

by JP Dalik

Why a 220a when the horsepower is t even 250. Looks like a 210 cummins maybe 250 at best without tombstone air cooler. Gonna be a 23kt cruise boat maybe use big acme or dqx 3 blades. Why all the hate speedy man.

Re: repower

Posted: Nov 30th, '15, 16:07

by bob lico

jp i am communicating with tom by pm. the differance between the ZF 63 and 220 irm is not a hp issue with this cummins 220hp installation .the problem is 2 degree differance in down angle because it is essential although differcult in a 31 bertram/cummins installation to keep the cummins as close to level as possible it is essential or number 1 cylinder will cook especially if build date is prior to 2004 (storm block) with small injectors,rotating exhaust valves,scuff resistant pistons,reshaped combustion chamber all redesign in the aftermath of cpl 970 days .i cannot watch a brother destroy a pair of engines especially when i knew better thats not with this board is all about.

Re: repower

Posted: Dec 1st, '15, 22:32

by bob lico

tom batteries in companion way centered and on bilge as low as possible like this

Re: repower

Posted: Dec 1st, '15, 22:37

by bob lico

10 degrees shaft angle with altered struct. note after filling gap on top of struct make contour around front pad of struct (faired)

Re: repower

Posted: Dec 1st, '15, 22:43

by bob lico

tom after shaft coupling only 4" of shaft showing with 220 irm and engines pull back as far as possible with up and over exhaust insulation on port touching engine cover!

Re: repower

Posted: Dec 2nd, '15, 12:27

by 1962 31

just ordered fiberglass logs and pss seals more grinding tonight !!!!!!!

what should I use for bolts to mount the strut? stainless? silicone bronze ?

Re: repower

Posted: Dec 2nd, '15, 12:37

by CaptPatrick

silicone bronze...

Re: repower

Posted: Jan 13th, '16, 09:52

by 1962 31

progress update

shaft logs are in just need final fairing

strut pads are in and done

second motor is all together and will be at the boat in next few days

raw water pickups are in

new control cables are in and brackets made for throttle on the motor side

redid fuel fill and vent hoses

all new motor mounts

pss dripless seals waiting to go in

fuel filters mounted and plumbed

going to make surge tubes do I need a special resin or will epoxy resin be ok for connection at the Y so to speak

Re: repower

Posted: Jan 13th, '16, 09:58

by CaptPatrick

going to make surge tubes do I need a special resin or will epoxy resin be ok for connection at the Y so to speak

Tom,

No! Epoxy won't take the heat of an exhaust system. Use either polyester or Vinylester resin for any construction that has to handle exhaust heat...

Re: repower

Posted: Jan 13th, '16, 10:17

by 1962 31

roger that

I have vinylester at the shop also ill use that

Re: repower

Posted: Jan 13th, '16, 10:19

by bob lico

tom did you go up and over placing the sprinkler head in the perfect vertical position for even cooling water distribution(no hot spots)?

Re: repower

Posted: Jan 13th, '16, 12:28

by Yannis

CaptPatrick wrote:silicone bronze...

Excuse me, but what is silicone bronze?

Thanks

Captain Pat, who has to come and what is there to take ? !!!

Re: repower

Posted: Jan 13th, '16, 16:38

by CaptPatrick

Excuse me, but what is silicone bronze?

a bronze with 2-3% silicon that is resistant to corrosion

who has to come and what is there to take ? !!!

Anybody who wants my guns... Originally made famous by King Leonidas I -- Applied today in the US by many second amendment supporters.

Re: repower

Posted: Jan 13th, '16, 21:09

by Tony Meola

Yannis

All bronze marine fittings, especially those in contact with Sea Water should be silicon bronze.

Re: repower

Posted: Jan 14th, '16, 13:06

by 1962 31

bob surge tubes and flaps for now this stuff is getting expensive lol

I had 90 percent of the stuff to do the exhaust ill build up and over next winter

on the shower head end of yours are there holes built in like the factory ones or does it just have an open cone

I cant find any pics of that end of the shower head on anyone's builds

Re: repower

Posted: Jan 14th, '16, 13:24

by Joseph Fikentscher

Re: repower

Posted: Jan 14th, '16, 14:05

by bob lico

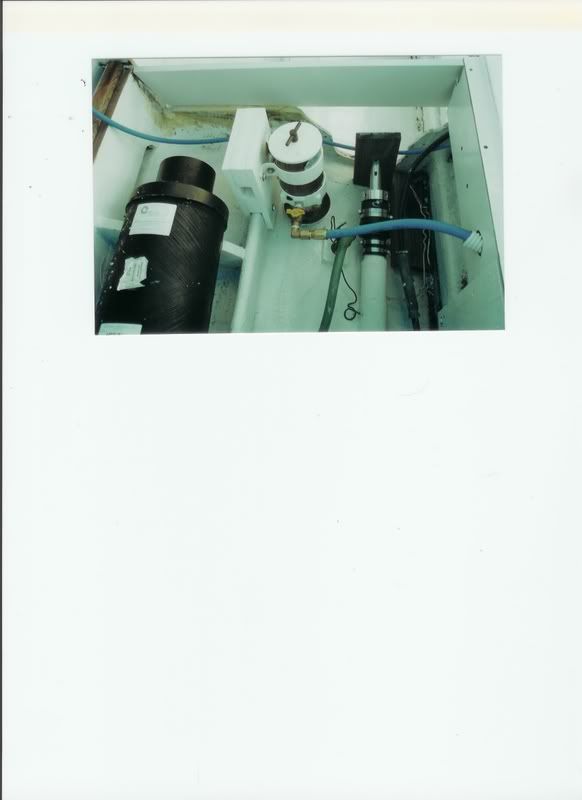

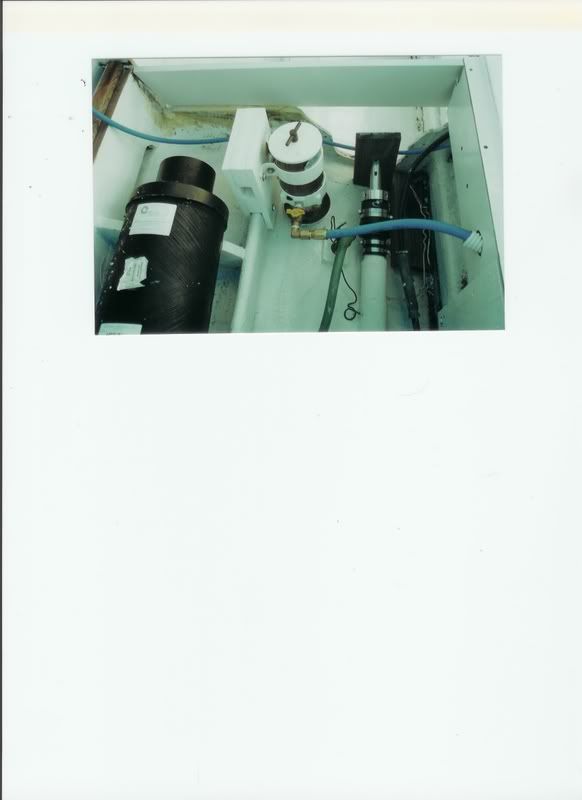

my sprinkler head has same holes as the Cummins OEM. 90 degree part. i went to the maximum height in engine compartment and then vertically straight down so cooling water is applied in a perfect circle to cool exhaust .this being said will last a hundred years and together with one way cone in muffler makes a surge tube totally useless.on a every times basis i run on one motor while offshore .i have try every way i could to slug a motor including backing down at excessive speed to put water over transom never happening trust me quite a bit of through went into the entire exhaust---------000000000 back pressure but thats another story.

Re: repower

Posted: Jan 14th, '16, 17:46

by bob lico

surge tubes would ruin the hold design of engine layout. port side has generator as partial counterweight the starboard has holding tank,gin pole support. those surge would take up precious space adjacent to engines and most important lose 10 hp .the mini mac mufflers shapes the outgoing exhaust in a circle around water flow so as not to impede exhaust but still get 1000percent surge protection.

Re: repower

Posted: Jan 14th, '16, 19:06

by Yannis

Has this motor ever run ?

Re: repower

Posted: Jan 14th, '16, 20:00

by bob lico

nine years straight with 0 down time .block heaters keep engines like new 24/7 . no condensation in engine compartment always warm to touch.

Re: repower

Posted: Jan 14th, '16, 20:29

by Navatech

bob lico wrote:nine years straight with 0 down time .block heaters keep engines like new 24/7 . no condensation in engine compartment always warm to touch.

I

think Yannis was giving you an oblique compliment... As in that engine looks so good it looks pristine... I.e. never run...

Re: repower

Posted: Jan 14th, '16, 21:01

by Tony Meola

Bob

Who makes a one way cone in muffler

?

Re: repower

Posted: Jan 14th, '16, 23:28

by bob lico

oh boy tony you are asking a major secret ,but for you anything.remember a little edge here and another edge here is how this boat has incredible fuel economy or speed if you want that instead. muffler is made by Centek inc. Minimax 1050600 a 6" inlet and 6" outlet 25" long and 10.04 in diameter.one way muffler because reverse cone is on inlet side.photo of installation under deck along outside 2" from hull side along stringer.

Re: repower

Posted: Jan 14th, '16, 23:39

by Tony Meola

Bob

Thank You

Re: repower

Posted: Jan 15th, '16, 08:20

by bob lico

oh yea tony that photo also illustrates the 10 degree shaft template------------oops

Re: repower

Posted: Jan 15th, '16, 08:59

by neil

Bob please give me a call thanks

Re: repower

Posted: Jan 15th, '16, 21:52

by Tony Meola

bob lico wrote:oh yea tony that photo also illustrates the 10 degree shaft template------------oops

Bob

Looks like Bertram took a page from your book for the 35. 10 degree shaft angle and a 22 degree deadrise.

Re: repower

Posted: Feb 1st, '16, 07:32

by 1962 31

Re: repower

Posted: Feb 1st, '16, 22:20

by Tony Meola

Tom

Looks like you are moving along.

If you have not replaced that bulkhead behind the engines, you might want to thing about it, or if it is in good shape, I would glass it in well.