Coolant leak

Moderators: CaptPatrick, mike ohlstein, Bruce

Coolant leak

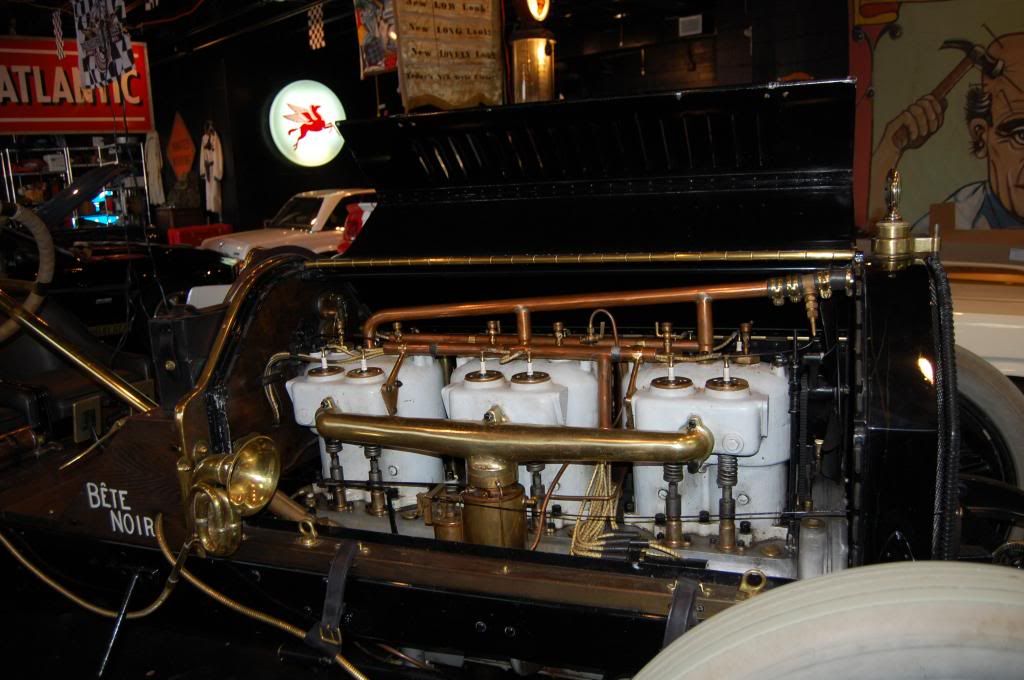

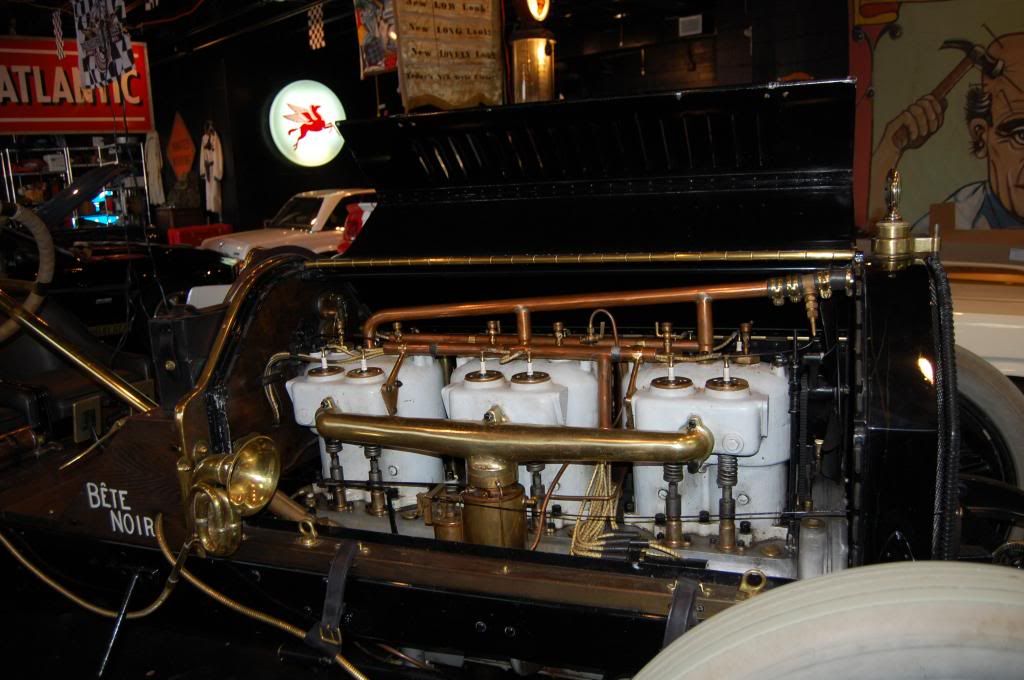

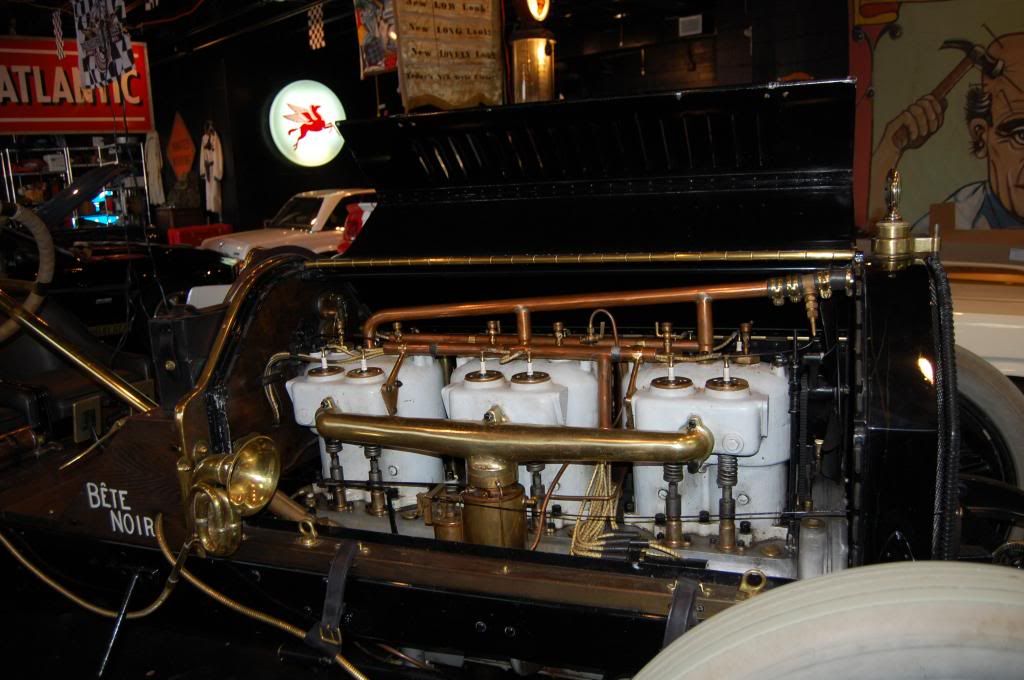

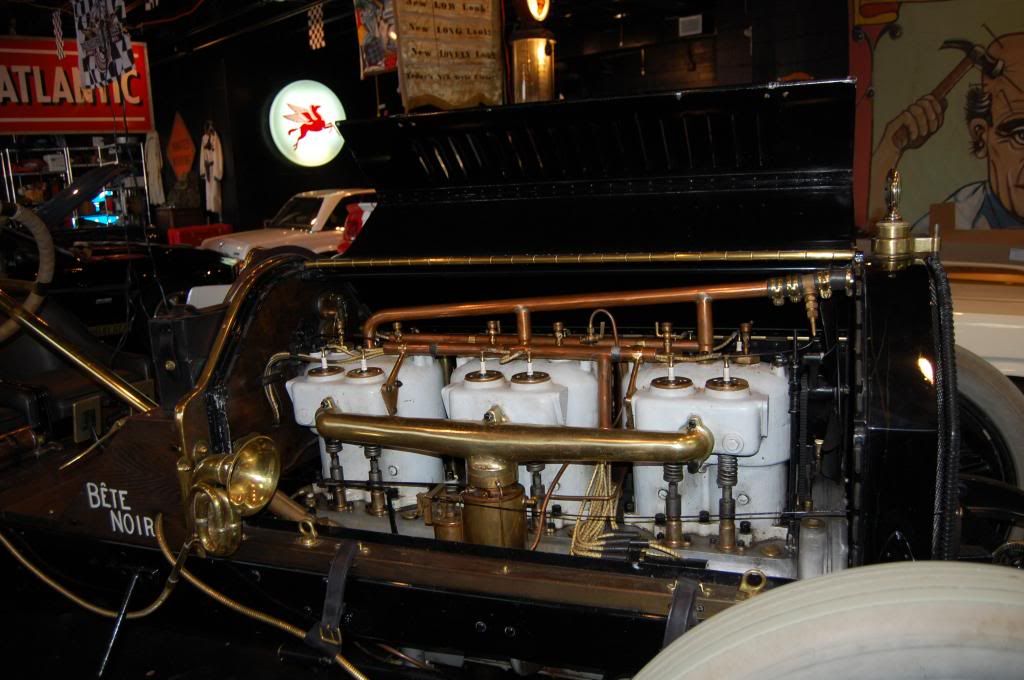

Pulling the hair out of my head cannot stop the 1909 Alco from leaking coolant from every joint. There are no gaskets in in 1909 and must keep original.there must be something better then black silicon any ideas?

capt.bob lico

bero13010473

bero13010473

Re: Coolant leak

Bob, what did they use for coolant in 1909? If it is leaking from every joint, then maybe the coolant needs to have bigger molecules, like nitrogen in tires?

-

Navatech

Re: Coolant leak

What's your source for the "There are no gaskets in in 1909" statement?!… I'm not so sure they didn't have gaskets in the early 20th century… I know for a fact they used flax, paper, copper, leather and cork gaskets in late 19th century steam operations… Also, it is my understanding that very small "modern" additions do not degrade the originality… I'd say that some "modernization" beats a leak pan…

Last edited by Navatech on Dec 11th, '13, 09:09, edited 1 time in total.

Re: Coolant leak

Bob,

Options I know of are:

Machine each surface and/or hand scrap/lap for a perfect metal to metal seal.

Taper mating surfaces.

Or use a gasket.

Gasket in the form of paper, felt, cork and copper.

Could also machine for an O-ring, but not sure how original that is...but if going in that direction

dope, silicone, rubber.

Or park it, drain it...

Options I know of are:

Machine each surface and/or hand scrap/lap for a perfect metal to metal seal.

Taper mating surfaces.

Or use a gasket.

Gasket in the form of paper, felt, cork and copper.

Could also machine for an O-ring, but not sure how original that is...but if going in that direction

dope, silicone, rubber.

Or park it, drain it...

Re: Coolant leak

Bob,

On many an old engine I've worked on where warpage or corrosion has caused non gasketed surfaces to leak, I found taking thin sheets of copper and making my own gaskets worked most of the time.

I would check the surfaces with a known true straight edge and feeler stock to check for warpage for the right gauge copper stock.

The other Issue I found on turn of the century engines were pulled threads that didn't allow bolts to hold tight. They would torque up, but not stay torqued. Blue loc tite helped that.

On many an old engine I've worked on where warpage or corrosion has caused non gasketed surfaces to leak, I found taking thin sheets of copper and making my own gaskets worked most of the time.

I would check the surfaces with a known true straight edge and feeler stock to check for warpage for the right gauge copper stock.

The other Issue I found on turn of the century engines were pulled threads that didn't allow bolts to hold tight. They would torque up, but not stay torqued. Blue loc tite helped that.

Re: Coolant leak

Bob PM me your address I will send you a couple of tubes of FIPG Toyota factory packing sealant. This sealant blows silicone away in every aspect and will adhere to metals even if there's a film of coolant between. I and everyone at Toyota swears by it... My thoughts are if you don't see the surface to be sealed, is anyone going to remove to check? I mean they're not going to tear your engine down like winning car right? If you seal it, and join the mating surfaces together I would think you would not see much, or any sealant when wiped with acetone and towel.

Re: Coolant leak

Bob-

Is this a new problem? This may be a bit weird...but, are there big temperature swings in the room, or is the sun baking it during the day? Might moving it to another part of the room and/or stabilizing the temperature help? Is the system vented?

It can come leak on my living room any time...

Best,

Stephan

Is this a new problem? This may be a bit weird...but, are there big temperature swings in the room, or is the sun baking it during the day? Might moving it to another part of the room and/or stabilizing the temperature help? Is the system vented?

It can come leak on my living room any time...

Best,

Stephan

Possunt quia posse videntur

Re: Coolant leak

Bob: What part is leaking? Permatex Anarobic sealant makes its own gasket, but cleans up with mineral spirits on the part not deprived of oxygen, so it doesn't look like a gasket after you clean it up. John Deere specs it from the factory on its transmissions and final drives instead of gaskets.

http://www.permatex.com/products-2/prod ... ker-detail" onclick="window.open(this.href);return false;

If it is a bolted on radiator tank seam tar roofing paper makes a great gasket, is not obvious and could be considered period correct.

http://www.permatex.com/products-2/prod ... ker-detail" onclick="window.open(this.href);return false;

If it is a bolted on radiator tank seam tar roofing paper makes a great gasket, is not obvious and could be considered period correct.

Rawleigh

1966 FBC 31

1966 FBC 31

Re: Coolant leak

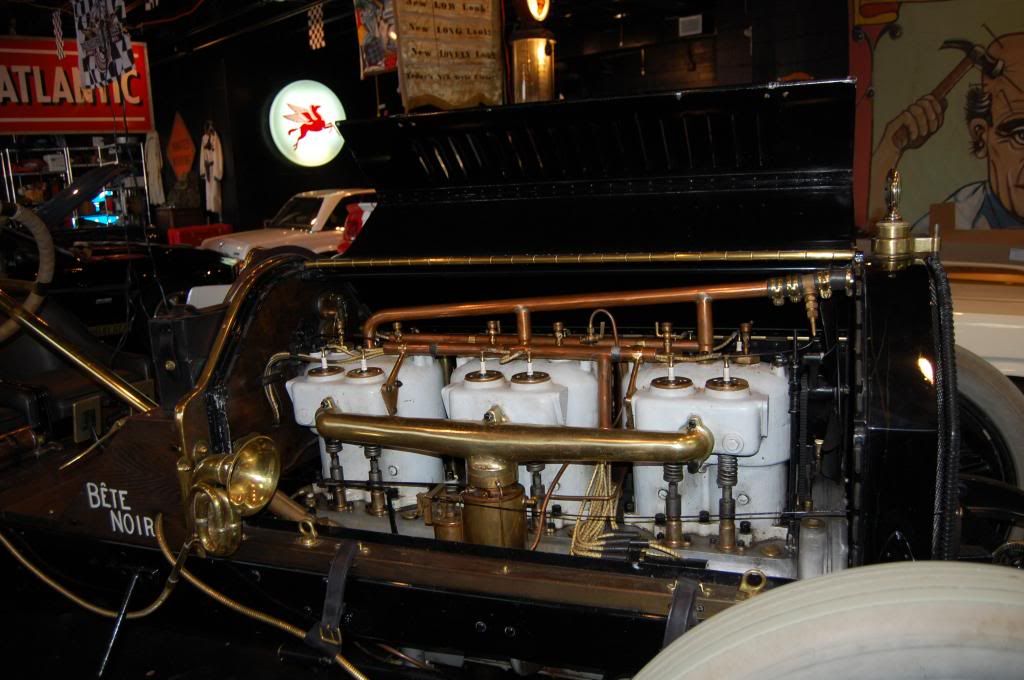

Here is a better photo you can see were the copper pipe from radiator meets the top of the block all three points leak. Carl it is a machine surface of head to a copper flange.i have been using permatex black silicon and it drip slightly but increase with drop in temperature ( garage is heated somewhat) .alco did not use a gasket at these three points nor the return flange to radiator.we have all the specs. Of the 1910 indy 500 race ( the first race of new track) they used water and added alcohol. The car was invited by Mario Andretti to run two laps at the Indy 2010 ----- 100 anniversary . She ran the two laps at 85mph and was greeted at fav winners circle by Mario .she did not leak a bit except oil from pan seam that day .bruce I believe that thin copper gasket would blend in with copper flange along with some type of thin sealant.

capt.bob lico

bero13010473

bero13010473

Re: Coolant leak

Bob: Anneal that copper gasket with a torch so that it will be dead soft. Knowing you i am sure that you have made sure the flanges and mating surfaces are perfectly flat.

Rawleigh

1966 FBC 31

1966 FBC 31

Re: Coolant leak

I took machinist tool steel parallels then wrap with 400 grit and oil and make figure 8 to make both surfaces perfectly flat. What can I say it still drip drop leaving a tell tale steak on block.

capt.bob lico

bero13010473

bero13010473

Re: Coolant leak

All three flanges soldered to common rail coming from radiator

I am thinking the Flanges may be flat but not 100% parallel to mating surfaces.

Sit the rail on the block. Do not bolt or push down. Now verify with feeler gauge or a light to make sure you have perfect contact all around...my guess is you will not. The bolts will pull the soft copper down with little effort...but may not seal as rail may be lifting the flange ever so slightly.

I'd expect to see gaps adjacent to the flange bolts where they have the least amount of clamping force.

Now find out what is out.

Check block ports with a lapped straight edge. Check with feeler gauge to see if flat and parallel.

Put the rails flanges on a Surface Plate, use a feeler gauge to check for gaps.

I am thinking the Flanges may be flat but not 100% parallel to mating surfaces.

Sit the rail on the block. Do not bolt or push down. Now verify with feeler gauge or a light to make sure you have perfect contact all around...my guess is you will not. The bolts will pull the soft copper down with little effort...but may not seal as rail may be lifting the flange ever so slightly.

I'd expect to see gaps adjacent to the flange bolts where they have the least amount of clamping force.

Now find out what is out.

Check block ports with a lapped straight edge. Check with feeler gauge to see if flat and parallel.

Put the rails flanges on a Surface Plate, use a feeler gauge to check for gaps.

Re: Coolant leak

Starting to get long faced cause I do not have micro- flat and all access to all those accurate machinist tools anymore.

capt.bob lico

bero13010473

bero13010473

Re: Coolant leak

Bob, it would be a ride for you and a $15.00 toll for the VZ Bridge...but you welcome to come by and use my stuff.

Not sure if my surface table is large enough at 24"...but we have other ways of checking.

I'd be somewhat at a loss if you needed to tweak...we have limited service work tooling left here these days.

Not sure if my surface table is large enough at 24"...but we have other ways of checking.

I'd be somewhat at a loss if you needed to tweak...we have limited service work tooling left here these days.

Re: Coolant leak

Bob: A good piece of float glass would make a decent surface plate. Try your sliding doors. Mist with water and stick 320 grit sand paper to the glass where the flanges land. Use a Sharpie or other permanent magic marker to blue the flanges and rub it on the glass in a circular motion. You may need a couple of extra hands for this. Reference the sanding pattern to see what is out and by how much.

Rawleigh

1966 FBC 31

1966 FBC 31

Re: Coolant leak

LOL...Rawleigh, you'll get Bob lynched for doing that. Whats funny is I was going to mention the granite or marble countertops I think I had seen in an ol' picture.Rawleigh wrote:Bob: A good piece of float glass would make a decent surface plate. Try your sliding doors. Mist with water and stick 320 grit sand paper to the glass where the flanges land. Use a Sharpie or other permanent magic marker to blue the flanges and rub it on the glass in a circular motion. You may need a couple of extra hands for this. Reference the sanding pattern to see what is out and by how much.

-

Navatech

Re: Coolant leak

Back in my merchant marine days we had a thick slab of glass to do our lapping on…

Re: Coolant leak

That is right! Those kitchen counters would be perfect!!Carl wrote: LOL...Rawleigh, you'll get Bob lynched for doing that. Whats funny is I was going to mention the granite or marble countertops I think I had seen in an ol' picture.

Rawleigh

1966 FBC 31

1966 FBC 31

Re: Coolant leak

Carl wrote:Bob, it would be a ride for you and a $15.00 toll for the VZ Bridge...but you welcome to come by and use my stuff.

Not sure if my surface table is large enough at 24"...but we have other ways of checking.

I'd be somewhat at a loss if you needed to tweak...we have limited service work tooling left here these days.

I have surface tables here at work up to 15' and can check it and a lot closer East Patchogue.

Let me know if you need my help Bob.

Dan

- PeterPalmieri

- Senior Member

- Posts: 2612

- Joined: Nov 12th, '10, 11:26

- Location: Babylon, NY

Re: Coolant leak

Dan,

Just noticed the link in your signature, nicely done.

Pete

Just noticed the link in your signature, nicely done.

Pete

1969 31 Bertram FBC "East Wind" hull #315939

Re: Coolant leak

Bob- In Hicksville I have several surface plates ( up to 20'x5') calibrated to laboratory grade. Call me at 516-931-1524, ask for John.

I think that Carl is on the right path, starting with the copper (1) the flanges on the copper manifold may be (a) not parallel to each other, or (b) not coincident or "even in height" with each other, or (c) both. If this is so then even though the copper flange is being pulled down by the two bolts, they do not distribute the force evenly enough to hold the entire flange perfectly flush against the mating surface of the head. This will result in a small gap.

(2) If the tubing flanges check perfect, or near perfect, then the issue lies with the faces on the block. I do not know who machined them but it is possible that they have the same conditions that we suspect on the tubing flanges. If so then they may need to be re-machined properly.

I know you said that Alco does not call out a gasket, but in dealing with a lot of products engineered many decades ago I have learned that does not mean that none were used. It may just mean, and please don't take offense here, that they assumed no one who was running one of these would be dopey enough not to put a suitable gasket material under there after work was performed. Alco engineers had a lot of experience with gaskets before they made this car, and Permatex was being used as a gasket material on race cars here in New York as early as 1915 because existing gasket materials were unreliable. Anyway, enough of my rambling, call me at the number above and we will help you figure out what is happening. I think that you are doing yourself and the car a dis-service when so quickly dismissing a gasket, especially period accurate like cork, tar, (or Permatex)

I think that Carl is on the right path, starting with the copper (1) the flanges on the copper manifold may be (a) not parallel to each other, or (b) not coincident or "even in height" with each other, or (c) both. If this is so then even though the copper flange is being pulled down by the two bolts, they do not distribute the force evenly enough to hold the entire flange perfectly flush against the mating surface of the head. This will result in a small gap.

(2) If the tubing flanges check perfect, or near perfect, then the issue lies with the faces on the block. I do not know who machined them but it is possible that they have the same conditions that we suspect on the tubing flanges. If so then they may need to be re-machined properly.

I know you said that Alco does not call out a gasket, but in dealing with a lot of products engineered many decades ago I have learned that does not mean that none were used. It may just mean, and please don't take offense here, that they assumed no one who was running one of these would be dopey enough not to put a suitable gasket material under there after work was performed. Alco engineers had a lot of experience with gaskets before they made this car, and Permatex was being used as a gasket material on race cars here in New York as early as 1915 because existing gasket materials were unreliable. Anyway, enough of my rambling, call me at the number above and we will help you figure out what is happening. I think that you are doing yourself and the car a dis-service when so quickly dismissing a gasket, especially period accurate like cork, tar, (or Permatex)

Re: Coolant leak

john, carl you were right all three flanges flat but not parallel and there was tar between mating surfaces .i guess this is what they used in 1909. i put manifold in garage and went down stairs (while the bear slept) and checked on her 17' of granite counter . feeler gauge proved not parallel. you were not serious about using outside opening doors i hope! i would be another dwayne bobick or at least sleep with one eye open.

capt.bob lico

bero13010473

bero13010473

Re: Coolant leak

ok now to correct problem i cannot use dining room doors without repercussions.

i will go with copper gaskets that should take up .015 out of parallel condition really have to put the torque effect the bolts would have on this .i want to thank rocky carl,john,bruce and al the rest of my brothers whom contributed to repairing this ALCO. this car is also is a one of two in the world so we must keep original.

i will go with copper gaskets that should take up .015 out of parallel condition really have to put the torque effect the bolts would have on this .i want to thank rocky carl,john,bruce and al the rest of my brothers whom contributed to repairing this ALCO. this car is also is a one of two in the world so we must keep original.

capt.bob lico

bero13010473

bero13010473

Re: Coolant leak

Countertop was only meant as ballpark means of checking for straightness.

If out of parallel by .015 as you say....I am not feeling overly confident a Copper gasket will take up that kind of non uniform gap.

If flanges are parallel but at different heights...you'll have a fighting chance shimming the larger spaces with copper gaskets.

This is not my area...

If out of parallel by .015 as you say....I am not feeling overly confident a Copper gasket will take up that kind of non uniform gap.

If flanges are parallel but at different heights...you'll have a fighting chance shimming the larger spaces with copper gaskets.

This is not my area...

Re: Coolant leak

Not to flog a dead horse, but the Permatex Anaerobic Gasket and Flange Sealer states the it will bridge a 0.015" gap.

http://www.permatex.com/products-2/prod ... 845-detail" onclick="window.open(this.href);return false;

http://www.permatex.com/products-2/prod ... 845-detail" onclick="window.open(this.href);return false;

Rawleigh

1966 FBC 31

1966 FBC 31

Re: Coolant leak

Thanks Rawleigh was not aware of that. Seriously would you really use your patio doors to lap flange flat?

Last edited by bob lico on Dec 17th, '13, 15:01, edited 1 time in total.

capt.bob lico

bero13010473

bero13010473

Re: Coolant leak

I want to also tell the brotherhood that this is the Only sealant we use in the shop on ZF gears from pump to main body as well as pump housing there are NO gaskets In the three pieces that make up pump mechanism of ZFgears this is also what we use on Yamaha outboard power head seals again no gasket.i did not know it was good for up to .015 .

capt.bob lico

bero13010473

bero13010473

Re: Coolant leak

Bob: There are no gaskets in the transmissions and rear finals on John Deere tractors either. That is how I came to know of it.

To answer your other question, I would have before i was married!! A glass top table might be a better choice.

To answer your other question, I would have before i was married!! A glass top table might be a better choice.

Rawleigh

1966 FBC 31

1966 FBC 31

Re: Coolant leak

Rawleigh I sort of surrendered the interior of house to the bride I just do the construction work with this in mind there is no hassle with corvette,racing,skydiving ,Bertram,hunting,fishing.i assemble the manifold on ALCO with no leaks I used dead soft copper gasket on center only and your sealant.started her up ------ no water leaks from the manifold once again thank for all the offers,advice.

capt.bob lico

bero13010473

bero13010473

-

Navatech

Re: Coolant leak

Under the pressure of the screws and the heat of the coolant that casket will turn hard… If you ever need to open that manifold and want to reuse that gasket you will have to anneal that gasket… After which you can reuse the gasket… An advantage of such gaskets…bob lico wrote:I used dead soft copper gasket

Re: Coolant leak

Great Bob sounds like you got it. See, what else can collective minds do- anything! Glad to hear she's repaired.

Re: Coolant leak

Rocky I have a another winter project with my 1971 corvette . I am prepping it for 150mph running .i have purchase the entire front suspension ; springs,ball joints,upper and lower control arm bushings,sway bar,etc . I cannot get the lower ball joint off passenger side. I am using fork with air impact and Crc. Will not budge I guess 42 years in place has something to do with it! Any ideas like possibly controlled flame of torch on spindle mount?

capt.bob lico

bero13010473

bero13010473

Re: Coolant leak

Bob, a picture is worth a thousand words.bob lico wrote:Rocky I have a another winter project with my 1971 corvette . I am prepping it for 150mph running .i have purchase the entire front suspension ; springs,ball joints,upper and lower control arm bushings,sway bar,etc . I cannot get the lower ball joint off passenger side. I am using fork with air impact and Crc. Will not budge I guess 42 years in place has something to do with it! Any ideas like possibly controlled flame of torch on spindle mount?

- Harry Babb

- Senior Member

- Posts: 2354

- Joined: Jun 30th, '06, 21:45

- Location: Fairhope Al

- Contact:

Re: Coolant leak

Bob if you are talking about removing the "Tapered Joint" from the Spindle.....try this......Put a sledge hammer on one side if the spindle forging.....where the tapered detail of the ball joint is located......this is used as a backup......then take the largest hammer that you can swing and hit the spindle forging opposite of the position of the sledge hammer.....or use an Impact hammer instead of swinging a hammer......the big trick is to back up the impact with something that has mass.....in this situation I would avoid heat....Bob wrote:I cannot get the lower ball joint off passenger side. I am using fork with air impact and Crc. Will not budge I guess 42 years in place has something to do with it! Any ideas like possibly controlled flame of torch on spindle mount?

If you are talking about removing the "Ball Joint'" from the "A" frame......I like to remove the "A" frame from the car and use a hydraulic press for both removal and installation.

Really not to bad of a job.......I have done dozens of them......

Got pics????

hb

hb

Re: Coolant leak

gentleman this is the lower ball joint in the car as you can see the upper ball joint has already broken loose the lower one refuses to move.

capt.bob lico

bero13010473

bero13010473

Re: Coolant leak

here is the spindle off the opposite side. you can see the holes that the taper shaft of the ball joint goes in to. the lower ball joint tapered shaft is frozen into the bottom spindle hole. i have used air impact fork with manual adapter to strike with sledge hammer still will not move. harry this is why i ask about heat? don't want to harm spindle .

capt.bob lico

bero13010473

bero13010473

- Harry Babb

- Senior Member

- Posts: 2354

- Joined: Jun 30th, '06, 21:45

- Location: Fairhope Al

- Contact:

Re: Coolant leak

Bob.......have your helper hold a sledge hammer good and tight against the backside of the tapered area of the ball joint connection.....using it as a "Bucking Tool"........then strike the face that we see in the photo with a good solid hard blow......I assure you that if you follow these instructions the ole girl will give up and come apart.......simply hitting with a sledge hammer will not necessarily do it....but if you "Buck" the tapered joint with a heavy weight .... and I do mean heavy.....while you knock the stew out of it on the front side it will work......I promise......DON'T MAKE ME HAVE TO COME UP THERE! ! ! ....LOL!!

HB

HB

hb

Re: Coolant leak

Yes, a 3 lb short sledge on the spindle taper is how I've done many ball joint removals. Heat won't be necessary I've never needed it. Hit it square to the taper with spindle turned all the way for room and I mean don't make love to it, HIT IT. It will pop. Years ago I converted my sister's '67 Camaro over to disk in front, those ball joints were a rusted mess but same technique on taper, all four no prob. If you are concerned about dinging spindle you could you a brass drift but loose effectiveness from blow this way. I have always had better results from outside taper rather than fork on the difficult ones. Nothing like a shock on the interference fit from the outside.

Re: Coolant leak

Finally I resorted to a large cold chisel to add dimension to the fork that worked on the other three but was to small for the last joint. Now on to to the supposedly hard part that is the removal of bushings from upper and lower A frame to install poly bushings.i will keep this thread going due to the worst of the winter setting in. Maybe some deer hunting with shotgun in January on eastern LI.

capt.bob lico

bero13010473

bero13010473

Re: Coolant leak

Air chisel with a, well, chisel on it and collapse the sides of bushing casing inward, then direct air chisel to push casing out. You can also get high tech and press them out with special arbors but air chisel works every time for me. Just be careful of not hitting A-arm with it, you can see OK. right Bob? Just checking!

Re: Coolant leak

Rawleigh the alco stop leaking I appreciate all the information you guys provided except the the use of "her" beloved house to test parts you guys no the story.Rawleigh wrote:Bob: There are no gaskets in the transmissions and rear finals on John Deere tractors either. That is how I came to know of it.

To answer your other question, I would have before i was married!! A glass top table might be a better choice.

capt.bob lico

bero13010473

bero13010473

Re: Coolant leak

LOL!! Glad it worked Bob! Sometimes we have to resort to the wonders of modern chemistry even on restored equipment. It is a beautiful one of a kind car for sure.

Rawleigh

1966 FBC 31

1966 FBC 31

Re: Coolant leak

Bob, Deer sesaon still on until? we shut down on 12-31. The bucks are all dropping their antlers up here, no acorns, stress, artic -2 weather. Knock one over for me.

Great car, glad you got the leak fixed..BH

Great car, glad you got the leak fixed..BH

1966 31 Bahia Mar #316-512....8 years later..Resolute is now a reality..Builder to Boater..285 hours on the clocks..enjoying every minute..how many days till spring?

Re: Coolant leak

Bob we have a special shot gun only season on shelter island . Family has a house with two acre plot which qualifies for nuisance permit ( shoot one and DEC issues new permit).the snow is almost totally gone and makes for hard tracking on frozen ground.

capt.bob lico

bero13010473

bero13010473

Who is online

Users browsing this forum: No registered users and 196 guests