Running Gear - upgrades/maintenence

Moderators: CaptPatrick, mike ohlstein, Bruce

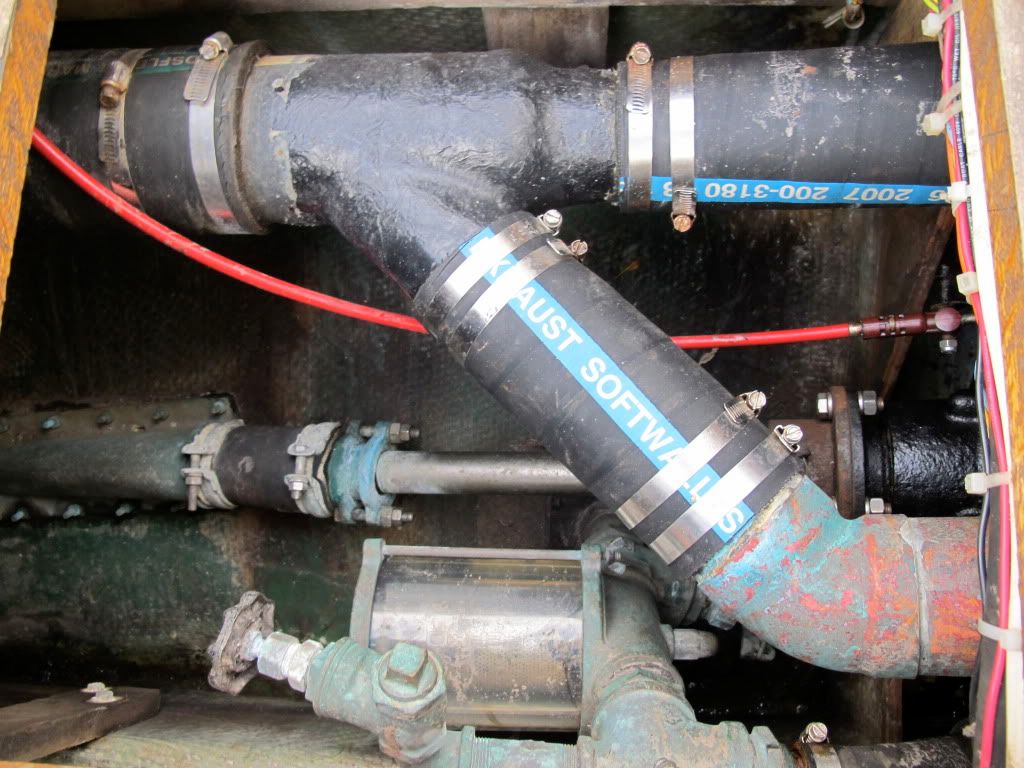

yes the coasties want two clamps but in my case the boat was built for at least three generations .working on boats for 50 years tells you quite a bit, for instance the bilge pumps most beat "the bad luck systrom" .every time a bilge pump hose breaks it is always right after the double clamp! look closely you will see a collar on each bilge hose where it connects to the pump. next i use one titanium clamp rather then two cheap clamps whereby the second clamp rest on nothing because the outlet pipe is so short . next is a one way valve and finally all 6 bilge pumps exit under the gunnel next to stern on port and starboard . when that goes under the boat is sitting on the bottom. exhaust and raw water use special t- bar clamps on BARB bronze fittings.

capt.bob lico

bero13010473

bero13010473

If you can tackle a few projects on your own and have marina address the Running Gear as planned...you should be able to get her Seaworthy and ready to use without breaking the bank.

The original rudders...while not the best I have run 17 years with mine shes a 62. I troll all the time on a single motor sometimes with the aid of an auto pilot...other times without and other then docking or trying to push her hard I do not have a problem running on a single motor. Response of the wheel at cruise is lacking,,,I've run 50footers that will respond faster at cruise...but I'm only cruising 19mph so I really don't need sports car like steering. It's on my list of things to do...but pockets are only so deep.

Get boat safe and running then address what concerns you the most...it may be the lackluster steering...it may be the need for crash pumps...it may be new cushions for the Miss'es...it may be a new Flyrod...

The original rudders...while not the best I have run 17 years with mine shes a 62. I troll all the time on a single motor sometimes with the aid of an auto pilot...other times without and other then docking or trying to push her hard I do not have a problem running on a single motor. Response of the wheel at cruise is lacking,,,I've run 50footers that will respond faster at cruise...but I'm only cruising 19mph so I really don't need sports car like steering. It's on my list of things to do...but pockets are only so deep.

Get boat safe and running then address what concerns you the most...it may be the lackluster steering...it may be the need for crash pumps...it may be new cushions for the Miss'es...it may be a new Flyrod...

- PeterPalmieri

- Senior Member

- Posts: 2612

- Joined: Nov 12th, '10, 11:26

- Location: Babylon, NY

Unfortunately i think rudders are off the list for the 2011 season.

Just paid the tax bill, documentation and registration. Got an estimate on a cockpit cover for the winter. And at this point i am getting some pricing on electrical expenses.

Without question i have to address the props and cutlass bearings in the spring. It makes sense to do the shaft logs and stuffing boxes. If my budget allows i will also consider the raw water intake / crash valves at that time. Id love to address everything that you all have suggested but Rome wasnt built in a day and budget will only go far. Im not one to extend myself.

If that means a season of inshore fishing and weekend trips to the beach that wont be disappointing. Keeping in mind the majority of my fishing is done on my flats boat already.

That doesnt mean i havent been keeping a list of all the suggestions and if anyone feels. I should reconsider my priorities that would be ok too.

Pete

Just paid the tax bill, documentation and registration. Got an estimate on a cockpit cover for the winter. And at this point i am getting some pricing on electrical expenses.

Without question i have to address the props and cutlass bearings in the spring. It makes sense to do the shaft logs and stuffing boxes. If my budget allows i will also consider the raw water intake / crash valves at that time. Id love to address everything that you all have suggested but Rome wasnt built in a day and budget will only go far. Im not one to extend myself.

If that means a season of inshore fishing and weekend trips to the beach that wont be disappointing. Keeping in mind the majority of my fishing is done on my flats boat already.

That doesnt mean i havent been keeping a list of all the suggestions and if anyone feels. I should reconsider my priorities that would be ok too.

Pete

1969 31 Bertram FBC "East Wind" hull #315939

Hey Peter

If you can find someone who can weld bronze and not charge an arm and a leg, you can add onto your existing rudders and have oversized rudders for much less money. That is the route I went. Add 1" or 2" to the bottom and back and you are good to go.

One of the guys on the old B28 board knew how to weld and did his own for $150.

Cliff

If you can find someone who can weld bronze and not charge an arm and a leg, you can add onto your existing rudders and have oversized rudders for much less money. That is the route I went. Add 1" or 2" to the bottom and back and you are good to go.

One of the guys on the old B28 board knew how to weld and did his own for $150.

Cliff

i don`t want to create the wrong impression on coasties but it like one shirt fits all -----not real. recent years the blubliners compounded the bilge pump problem . they put plastic thru-holes 1" above water line in the cheap tape boot stripe ok now the cheap made in china clamp breaks or the hose splits right at the clamp point . rain comes down ,bilge pump just cirulates water and boat sinks to boot stripe the sea comes in at thru- hole thru broken pipe and down she goes or the thru hole rubs the dock and breaks .that is reality!!!! now knowing anything that can go wrong will go wrong at the worst possible time. you raise the thru hole to gunnel ,use a "hose cuff"on bilge hose available from hamilton marine and titanium hose clamps or at least primium 316 all ss made in USA.titanium clamps are avaluble from jamestown distributors. you can tighten chine clamps until they click that means the worm has skip in the slot--------junk you can use three still junk. i get special t-bar from diesel power services if anybody wants then i can find his source.

capt.bob lico

bero13010473

bero13010473

- scenarioL113

- Senior Member

- Posts: 690

- Joined: May 31st, '08, 09:00

- Location: Massapequa Park, NY

cmccool wrote:Hey Peter

If you can find someone who can weld bronze and not charge an arm and a leg, you can add onto your existing rudders and have oversized rudders for much less money. That is the route I went. Add 1" or 2" to the bottom and back and you are good to go.

One of the guys on the old B28 board knew how to weld and did his own for $150.

Cliff

I did the same thing! It was another situation where I did something after being told "it couldn't be done".

I cut strips from a bronze rudder that had a bent shaft that was given to me. I made 4 strips out of it and added a strip to the rear and bottom of each of my rudders.

It made a HUGE difference and I can steer over an engine and make a turn.

I MIG welded mine with Silicon Bronze wire and 100% Argon shielding gas.

They have been through 5 seasons and not a hitch.

1971 28 Bertram

4BT Cummins

Frank

9-11-01 NEVER FORGET

4BT Cummins

Frank

9-11-01 NEVER FORGET

- PeterPalmieri

- Senior Member

- Posts: 2612

- Joined: Nov 12th, '10, 11:26

- Location: Babylon, NY

- Capt Dick Dean

- Senior Member

- Posts: 336

- Joined: Dec 17th, '06, 15:33

- Location: Long Island, N.Y.

- Contact:

- PeterPalmieri

- Senior Member

- Posts: 2612

- Joined: Nov 12th, '10, 11:26

- Location: Babylon, NY

peter that photo of phoenix is taken while the boat is hard over to port . look how the stern is "planted" in the water at 34knts .that is due to the rudders ,i would treat that project as a priority. the water breaks under the trailing edge of the side windows at all speeds above 21knts . the boat is absolutely dry ,so much so that when i come to a location to drift fish, i sit on the dry covering boards ,find it relaxing.that is done by shifting the weight and keeping all heavy items (like batteries) right down the centerline.bow proud is very important to boats charateristic in big seas as well as dry boat.we will discussed this later on in your new project .

capt.bob lico

bero13010473

bero13010473

- PeterPalmieri

- Senior Member

- Posts: 2612

- Joined: Nov 12th, '10, 11:26

- Location: Babylon, NY

Bob do you have your batteries in the centerline of the boat just aft of the v berth? I think i saw a picture of someones boat that was set up that way.

My head is spinning a little with all this stuff as ive spent the past two weeks reading through all 99 pages of posts in the general discussion forum.

My head is spinning a little with all this stuff as ive spent the past two weeks reading through all 99 pages of posts in the general discussion forum.

1969 31 Bertram FBC "East Wind" hull #315939

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

Nix... Too much weight forward of the engines. A properly loaded B31 will have 40% of it's weight forward of the forward engine bulkhead and 60% aft of the forward engine bulkhead. All weight should be concentrated on center line and spreading out, as evenly as possible, outboard.

I personally prefer the batteries to be center line and between the engines under the companionway.

Properly loaded, a B31 will run bow proud without tabs. Tabs can be useful for trim corrections and lowering the bow when needed.

I personally prefer the batteries to be center line and between the engines under the companionway.

Properly loaded, a B31 will run bow proud without tabs. Tabs can be useful for trim corrections and lowering the bow when needed.

- In Memory Walter K

- Senior Member

- Posts: 2912

- Joined: Jun 30th, '06, 21:25

- Location: East Hampton LI, NY

- Contact:

Rocky-If that's what you have, fine. My question is, with gassers, why? I may get arguments on this, but it seems to be overkill. It's always good to have more rather than less, but in this case you also have more weight, more space used and tougher (fork lift?) installation and removal. I have 4D's installed in boxes outboard of my Cummins and with my mate can remove them by hand when they need replacement. I do have a set of deep cycle 12v in parallel in between my engines for "house batteries". Just a thought.

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

peter do you remember as a teenager in high school you read how american built sailing ships that were the fastest in the world and sailed back anf forth to the orient . ships like the "cutty sark" were the pride of america. tremedous square footage of sail stabalize by ballast place down the centerline of the keel. capt. patrick was there ask him!! only kidding but that theory is the best for a 31 bertram . first of all it adversly effects roll . the weight down the center in the bilge IS the whole deal on centroid of gravity . the boat tends to right itself much quicker , next batteries must go in center just behind bulkhead-------no exceptions!!! no 8d and no 4d you are buying new batteries forget that ancient stuff now you use fiberglass matt one car battery size (2750) takes the place of 8d but no water,acid,acid fumes,back breaking weight mine are untouched for 10 years O maintenace. they also recharged twice as fast. i use one starboard engine, one port engine and two house and generator . all isolated . here is the photo the raw water intake,crash valve,bilge pump is next compatment towards stern.the batteries can be purchase wholesale in deer park . sealed cover is off for photo . box is made of interlocked (rabbited joint) pvc and glue cost about $10.00.

capt.bob lico

bero13010473

bero13010473

sorry brother rocky i was referring to deer park long island right near peter`s boat, for you go to www.batterymart.com under odyssey size 2150.

capt.bob lico

bero13010473

bero13010473

- PeterPalmieri

- Senior Member

- Posts: 2612

- Joined: Nov 12th, '10, 11:26

- Location: Babylon, NY

- PeterPalmieri

- Senior Member

- Posts: 2612

- Joined: Nov 12th, '10, 11:26

- Location: Babylon, NY

- PeterPalmieri

- Senior Member

- Posts: 2612

- Joined: Nov 12th, '10, 11:26

- Location: Babylon, NY

Just revisiting this thread and reading through all the thoughtful comments. I'm now taking notes so I can have a plan.

I am planning on getting the boat over to the marina to come out of the water beginning of march.

At this point I am torn as to how far to take this project. Part of me says new shafts, engine mounts, stuffing boxes, shaft logs, cutlass bearings, props and rudders. Getting everything done right and not worry about it again. Also have to address the sw intake for the motors. If I go that route I wonder if going with 1.5 shafts makes sense even if I don't plan on going to diesel for 5 plus years?

The thoughts of repositioning the batteries in the centerline involves moving the holding tank (which is new) sw intake for the head and the macerator. It may make sense to not start working on rewiring the boat if the batteries are going to be moved and possibly move the SW intakes if I am doing this too.

I am willing to spend 5k and will go to 8k if I need to but no higher at this point.

Any thoughts?

I am planning on getting the boat over to the marina to come out of the water beginning of march.

At this point I am torn as to how far to take this project. Part of me says new shafts, engine mounts, stuffing boxes, shaft logs, cutlass bearings, props and rudders. Getting everything done right and not worry about it again. Also have to address the sw intake for the motors. If I go that route I wonder if going with 1.5 shafts makes sense even if I don't plan on going to diesel for 5 plus years?

The thoughts of repositioning the batteries in the centerline involves moving the holding tank (which is new) sw intake for the head and the macerator. It may make sense to not start working on rewiring the boat if the batteries are going to be moved and possibly move the SW intakes if I am doing this too.

I am willing to spend 5k and will go to 8k if I need to but no higher at this point.

Any thoughts?

1969 31 Bertram FBC "East Wind" hull #315939

- In Memory Walter K

- Senior Member

- Posts: 2912

- Joined: Jun 30th, '06, 21:25

- Location: East Hampton LI, NY

- Contact:

- PeterPalmieri

- Senior Member

- Posts: 2612

- Joined: Nov 12th, '10, 11:26

- Location: Babylon, NY

Walter, the starboard prop needs to be replaced as do the cutlass bearings. There are vibrations in both port and starboard at lower RPMs, during the survey the thought was that the shafts may be bent slightly. Pulling the the shafts opens the can of worms.

1969 31 Bertram FBC "East Wind" hull #315939

- In Memory of Vicroy

- Senior Member

- Posts: 2340

- Joined: Jun 29th, '06, 09:19

- Location: Baton Rouge, LA

Pete - as to the vibration, start wtih the props as that's usually where it comes from...the shafts can be "miked" to check for bends so you won't pull a good shaft. Cutless bearings can usually be replaced by a skilled worker without pulling the shafts. Engines out of alignment will cause the shakes too. Start with the easy stuff and work toward the hard. Small, cheap steps.....start wtih the props...

UV

UV

- Brewster Minton

- Senior Member

- Posts: 1795

- Joined: Jun 30th, '06, 07:44

- Location: Hampton Bays NY

- Contact:

- In Memory Walter K

- Senior Member

- Posts: 2912

- Joined: Jun 30th, '06, 21:25

- Location: East Hampton LI, NY

- Contact:

My thoughts completely. The boat looks very well maintained. The prop can of course create vibrations. So can a bad cutlass bearing. I wouldn't pull off a pair of shafts without doing those first. Rudders? That's an improvement fairly easily made and you'll be glad you did. Your first season of running will tell you a lot about what your priorities are. You may be very pleasantly surprised. I know you won't compromise safety. Walter

- PeterPalmieri

- Senior Member

- Posts: 2612

- Joined: Nov 12th, '10, 11:26

- Location: Babylon, NY

- In Memory Walter K

- Senior Member

- Posts: 2912

- Joined: Jun 30th, '06, 21:25

- Location: East Hampton LI, NY

- Contact:

Two different rudders don't help handling. I would like to hear what others think about my theory that two different length shafts could also create a vibration. My question is, are the shafts different lengths or are the engines mounted in different positions on each side? The distance the forward face of the prop hub is to the the rear of the struts/cutlass bearing should be the same.

- PeterPalmieri

- Senior Member

- Posts: 2612

- Joined: Nov 12th, '10, 11:26

- Location: Babylon, NY

That distance is the same. The difference is the threads stick past the prop after the nut and they don't onthe other prop. I don't have a picture and it was a few months since the boat was out of the water

Last edited by PeterPalmieri on Dec 22nd, '10, 20:52, edited 1 time in total.

1969 31 Bertram FBC "East Wind" hull #315939

- PeterPalmieri

- Senior Member

- Posts: 2612

- Joined: Nov 12th, '10, 11:26

- Location: Babylon, NY

- PeterPalmieri

- Senior Member

- Posts: 2612

- Joined: Nov 12th, '10, 11:26

- Location: Babylon, NY

- PeterPalmieri

- Senior Member

- Posts: 2612

- Joined: Nov 12th, '10, 11:26

- Location: Babylon, NY

Great advice. And if you're forced to fix something, fix it right so the problem won't reappear, or bandaid until you can get it right. Don't waste time/money doing something halfway that you'll be redoing in a few years. You may be surprised how fast you can go through $8K.Brewster Minton wrote:UV is right. Start with props. Use the boat and try not to spend any money unless you have to. As you start to understand her you will see what is next. Remember you may get forced to spend money to fix something that breaks. Just my 2 cents.

1968 B20 Moppie - Hull # 201-937

1969 B31 FBC - Hull # 315-881 (sold)

1977 B31 FBC - Hull # BERG1652M77J (sold)

1969 B31 FBC - Hull # 315-881 (sold)

1977 B31 FBC - Hull # BERG1652M77J (sold)

- PeterPalmieri

- Senior Member

- Posts: 2612

- Joined: Nov 12th, '10, 11:26

- Location: Babylon, NY

Thanks guys. I am off next week and will take some pictures. Any of you local guys who wouldn't mind popping down to the boat to take a look. Lunch would be on me.

You guys need to understand I have no experience with inboard motors. The only things I have any clue about is what I've read since I bought the boat. Even though I have 3 months before any of this happen I am trying to educate myself the best I can so I don't just hand the keys to the yard. I understand my budget isn't large and I just want to make sure I address things that are important.

While I'd love to drop in a set of cummins I realize that is not a reality anytime soon. So I want to get these 454s running the best I can so the boat is reliable. I also don't want to throw good money after bad so I want to address what needs attention. And hope to make sure I am not putting additional strain on anything that could be addressed before it becomes a problem.

You guys need to understand I have no experience with inboard motors. The only things I have any clue about is what I've read since I bought the boat. Even though I have 3 months before any of this happen I am trying to educate myself the best I can so I don't just hand the keys to the yard. I understand my budget isn't large and I just want to make sure I address things that are important.

While I'd love to drop in a set of cummins I realize that is not a reality anytime soon. So I want to get these 454s running the best I can so the boat is reliable. I also don't want to throw good money after bad so I want to address what needs attention. And hope to make sure I am not putting additional strain on anything that could be addressed before it becomes a problem.

1969 31 Bertram FBC "East Wind" hull #315939

- PeterPalmieri

- Senior Member

- Posts: 2612

- Joined: Nov 12th, '10, 11:26

- Location: Babylon, NY

Two different length shafts is not uncommon or a problem.

Before going to a yard and telling them you want two new shafts, I'd make sure you need them. Pull the shaft and have them checked out. Most shops, like mine do not charge for checking. In a boat you can only tell if it is way out of straightness. You also cannot tell if the Bearing and Packing area are worn and out of spec or if the coupling is face is running true.

Several Yard Mechanics around here will go in and if they cannot pull the shaft in a few minutes, they pull out the SawZall and hack the end of shaft with coupling off. I cannot tell you how many perfectly Good Shafts have had to be replaced because they where just Hacked off.

If one shaft end appears different...it may be. Years back some shops went with a Chris Craft style shaft...same taper...but ran the threads all the way to the end and used a Castled Nut and Cotter pin to secure. I prefer a standard tapered end...but for the cost of a new shaft I'd stick with what you have...provided it is machined properly, not pitting, straight and not worn over specs at the stuffing box or Bearing Area

Distance from back of wheel to Strut Bearing should be about 1.5 times the shaft diameter, plus or minus half the diameter is okay.

It's also possible the Prop may be riding the key and not sitting all the way back on the taper...it would cause your vibration....could also be one of the tapers is wrong...at the Shaft or the Prop.

Could be you need shafts...but if you don't its money for another project or two or three....

Before going to a yard and telling them you want two new shafts, I'd make sure you need them. Pull the shaft and have them checked out. Most shops, like mine do not charge for checking. In a boat you can only tell if it is way out of straightness. You also cannot tell if the Bearing and Packing area are worn and out of spec or if the coupling is face is running true.

Several Yard Mechanics around here will go in and if they cannot pull the shaft in a few minutes, they pull out the SawZall and hack the end of shaft with coupling off. I cannot tell you how many perfectly Good Shafts have had to be replaced because they where just Hacked off.

If one shaft end appears different...it may be. Years back some shops went with a Chris Craft style shaft...same taper...but ran the threads all the way to the end and used a Castled Nut and Cotter pin to secure. I prefer a standard tapered end...but for the cost of a new shaft I'd stick with what you have...provided it is machined properly, not pitting, straight and not worn over specs at the stuffing box or Bearing Area

Distance from back of wheel to Strut Bearing should be about 1.5 times the shaft diameter, plus or minus half the diameter is okay.

It's also possible the Prop may be riding the key and not sitting all the way back on the taper...it would cause your vibration....could also be one of the tapers is wrong...at the Shaft or the Prop.

Could be you need shafts...but if you don't its money for another project or two or three....

Last edited by Carl on Dec 30th, '10, 06:55, edited 1 time in total.

- PeterPalmieri

- Senior Member

- Posts: 2612

- Joined: Nov 12th, '10, 11:26

- Location: Babylon, NY

Thanks sim very helpful. I wen to the boat today no snow on it but a huge mound at the edge of the dock. I didn't bother digging my way in. Maybe by the weekend I can get some pictures of the coupling.

If I remember correctly one shaft had a cotter pin the other did not.

If I remember correctly one shaft had a cotter pin the other did not.

1969 31 Bertram FBC "East Wind" hull #315939

Ripping everything out and starting new is always an option...

Taking pictures of coupling..is nice. We all love pictures. I wouldn't spend too much time and effort trying to get pictures though. If you are removing shafts the couplings have to come off...and that's all we need to know now. I'd rather see pictures of the Shaft , Prop, Strut area...thats more telling.

If your thinking of going up a size or two as an upgrade for a diesel conversion, consider this. Depending on the motors and transmission you get it will require a different shaft length. If the shaft length you have is too long, no problem, you take shaft to a shop where they can cut and re-key to size then fit coupling for short money.

Now if your diesel conversion requires a longer shaft...no amount of cutting and re-keying will make it longer...so you'll be shelling out money for new shafts again.

See what you have to work with...if one or both are toast, then toss them or save as spares. That is unless you have unlimited funds to work with...then new is always nice.

Taking pictures of coupling..is nice. We all love pictures. I wouldn't spend too much time and effort trying to get pictures though. If you are removing shafts the couplings have to come off...and that's all we need to know now. I'd rather see pictures of the Shaft , Prop, Strut area...thats more telling.

If your thinking of going up a size or two as an upgrade for a diesel conversion, consider this. Depending on the motors and transmission you get it will require a different shaft length. If the shaft length you have is too long, no problem, you take shaft to a shop where they can cut and re-key to size then fit coupling for short money.

Now if your diesel conversion requires a longer shaft...no amount of cutting and re-keying will make it longer...so you'll be shelling out money for new shafts again.

See what you have to work with...if one or both are toast, then toss them or save as spares. That is unless you have unlimited funds to work with...then new is always nice.

- In Memory of Vicroy

- Senior Member

- Posts: 2340

- Joined: Jun 29th, '06, 09:19

- Location: Baton Rouge, LA

Pete - since this is your first experience with straight inboard drive, relax some. It is incredibly simple vs. an outboard or I/O. Nothing underwater to leak oil out and water in, no gears underwater, no slip hubs on props. The straight inboard has worked for 200 years and is still the drive of choice for reliability.

My point is.......don'w worry too much about a little vibration, they all do it to some extent. Before you spend a dime, run the boat a good bit and get familiar with how it feels and sounds - that will give you a baseline to work from....KISS, and the enemy of good is better.

UV

My point is.......don'w worry too much about a little vibration, they all do it to some extent. Before you spend a dime, run the boat a good bit and get familiar with how it feels and sounds - that will give you a baseline to work from....KISS, and the enemy of good is better.

UV

Who is online

Users browsing this forum: No registered users and 329 guests