ZF45a Linkage relocation comments.....

Moderators: CaptPatrick, mike ohlstein, Bruce

- scenarioL113

- Senior Member

- Posts: 690

- Joined: May 31st, '08, 09:00

- Location: Massapequa Park, NY

ZF45a Linkage relocation comments.....

I have a pair of ZF45a's ib my B28. They are behind a pair of cummins 4BT's. As discussed in another thread I had to unfortunately replace the original gas tank, it was destroyed.

After finding a tank that would fit (and fit into my budget!) I realized there would be a clearance issue on the starboard side for the cable to attach to the transmission.

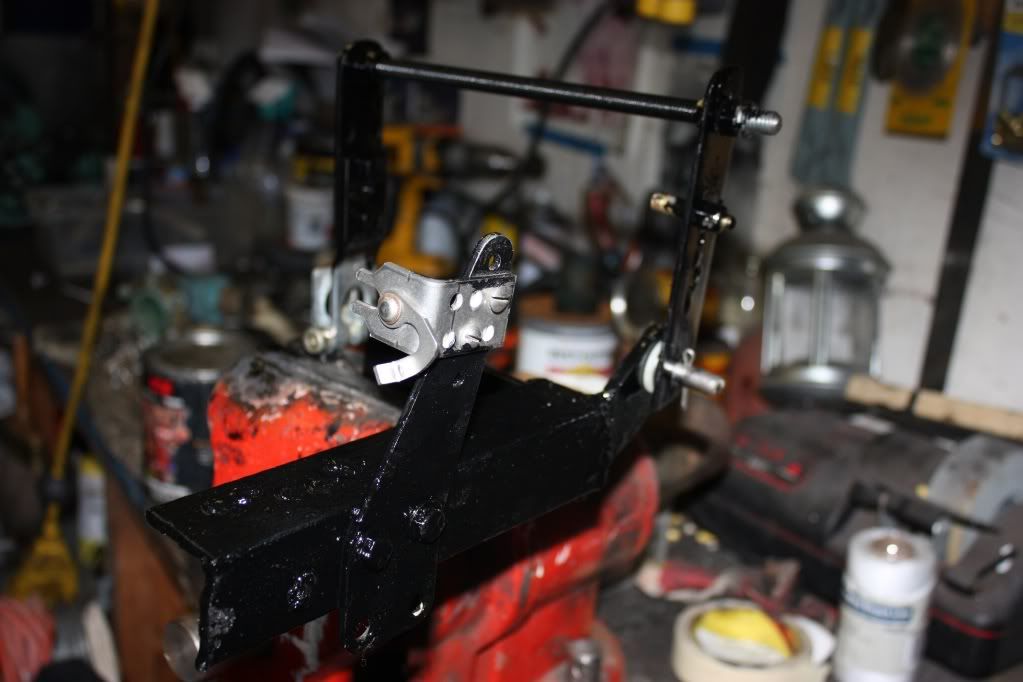

I thought about a few different ways to mount the linkage but it was just going to be a problem no matter what I did. I decided to fabricate a bracket that attaches to the original bracket and crosses over the transmission so the cable does no interfere with the new fuel tank.

The new bracket functions perfect and I guess if I keep it painted and greased it should not rust too bad. I will just have to keep an eye on it.

I attached the bracket to two threaded holes on the transmission that do not get used on my application (I think).

I looked through the manual and I could not see why I would have a problem attaching the bracket to this area.

I will post pics.

After finding a tank that would fit (and fit into my budget!) I realized there would be a clearance issue on the starboard side for the cable to attach to the transmission.

I thought about a few different ways to mount the linkage but it was just going to be a problem no matter what I did. I decided to fabricate a bracket that attaches to the original bracket and crosses over the transmission so the cable does no interfere with the new fuel tank.

The new bracket functions perfect and I guess if I keep it painted and greased it should not rust too bad. I will just have to keep an eye on it.

I attached the bracket to two threaded holes on the transmission that do not get used on my application (I think).

I looked through the manual and I could not see why I would have a problem attaching the bracket to this area.

I will post pics.

1971 28 Bertram

4BT Cummins

Frank

9-11-01 NEVER FORGET

4BT Cummins

Frank

9-11-01 NEVER FORGET

- scenarioL113

- Senior Member

- Posts: 690

- Joined: May 31st, '08, 09:00

- Location: Massapequa Park, NY

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

Good job of problem solving. Only thing I see is the possible lateral stability by changing the direction of the cable 90º through the all thread cross over. While the shift lever on the transmission offers little resistance, an addition of a diagonal strap will greatly increase the rigidity of your mod.

- scenarioL113

- Senior Member

- Posts: 690

- Joined: May 31st, '08, 09:00

- Location: Massapequa Park, NY

- Brewster Minton

- Senior Member

- Posts: 1795

- Joined: Jun 30th, '06, 07:44

- Location: Hampton Bays NY

- Contact:

- scenarioL113

- Senior Member

- Posts: 690

- Joined: May 31st, '08, 09:00

- Location: Massapequa Park, NY

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

Corrosion-X You'll be wanting the RED lable

- chris pague

- Senior Member

- Posts: 159

- Joined: Jun 29th, '06, 13:43

- Location: wicimico ch va,22579

- scenarioL113

- Senior Member

- Posts: 690

- Joined: May 31st, '08, 09:00

- Location: Massapequa Park, NY

Shortening the height of the bracket will cause it to make contact with the hydraulic hoses that goto the cooler when the shifter is in the forward most position.

I am concerned about rigidity and I was thinking about welding it all together but the problem is one side needs to come apart so the bracket can be removed or installed on the transmission.

I have the locking nuts on the outside with a regular nut to the inside. I believe over time it is possible something could come loose. Right now with them tightened up it is good to go.

I could weld the inside nuts in place and one of the two locking nuts as well. This would only have one area that could loosen up. It would still allow the bracket to be removed and taken apart.

I also used polyethylene plastic washers where the bracket pivots on the right and loaded it with grease.

It really does function effortlessly though.

I am concerned about rigidity and I was thinking about welding it all together but the problem is one side needs to come apart so the bracket can be removed or installed on the transmission.

I have the locking nuts on the outside with a regular nut to the inside. I believe over time it is possible something could come loose. Right now with them tightened up it is good to go.

I could weld the inside nuts in place and one of the two locking nuts as well. This would only have one area that could loosen up. It would still allow the bracket to be removed and taken apart.

I also used polyethylene plastic washers where the bracket pivots on the right and loaded it with grease.

It really does function effortlessly though.

1971 28 Bertram

4BT Cummins

Frank

9-11-01 NEVER FORGET

4BT Cummins

Frank

9-11-01 NEVER FORGET

Scenario, If you do not have the clearance for Capt Pat's lateral bar(great safety idea) you could run a sleeve like Chris had the idea of, but have it in two over your threaded rod, both ends welded to the vertical pieces and at the center have the two ends spline to each other.That way you can still take it apart. (Whish I can do drawings like the Capt)! Just another thought.

Hi Frank, I was able to scan a drawing of what I was thinking. Hope this helps.

Rocky.

Hi Frank, I was able to scan a drawing of what I was thinking. Hope this helps.

Rocky.

Who is online

Users browsing this forum: No registered users and 199 guests