The aft bulkhead (the one with the windows and door to the cabin in it, right in front of the motors) is screwed in on top and down the sides a bit. Its tabbed in at the bottom where it meets the hull. Crows Nest had this small piece of aluminum trim running around the inside of the ceiling in the cabin where it meets the bulkhead. On the outside, there was a small piece of teak trim.

I took the aluminum trim out that was inside the cabin off, filled the gap with epoxy/filler, made a fillet, and then did a couple layers of tape. I plan on doing the same on the outside. Is this OK? I know how much these boats "work," and I don't want it to crack. From looking at some pictures, it seems like this is what some have done in their rebuilds. Yeah, I should've asked before I started.

Aft bulkhead - F'glassing it in?

Moderators: CaptPatrick, mike ohlstein, Bruce

Aft bulkhead - F'glassing it in?

1968 B20 Moppie - Hull # 201-937

1969 B31 FBC - Hull # 315-881 (sold)

1977 B31 FBC - Hull # BERG1652M77J

1969 B31 FBC - Hull # 315-881 (sold)

1977 B31 FBC - Hull # BERG1652M77J

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

Re: Aft bulkhead - F'glassing it in?

John,

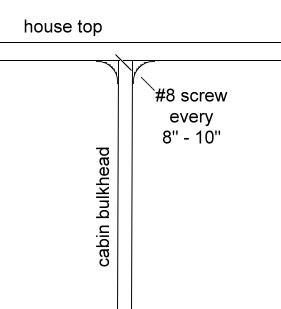

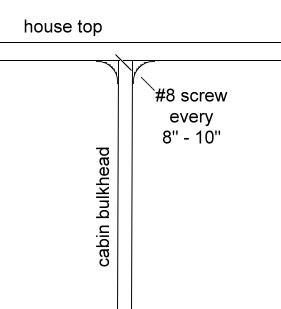

You should also lock the bulkhead into the boat with #8x1 1/2" screws, faired over with your fillet...

You should also lock the bulkhead into the boat with #8x1 1/2" screws, faired over with your fillet...

Br,

Patrick

Molon labe

Patrick

Molon labe

Re: Aft bulkhead - F'glassing it in?

Thanks Captain Patrick.

1968 B20 Moppie - Hull # 201-937

1969 B31 FBC - Hull # 315-881 (sold)

1977 B31 FBC - Hull # BERG1652M77J

1969 B31 FBC - Hull # 315-881 (sold)

1977 B31 FBC - Hull # BERG1652M77J

Re: Aft bulkhead - F'glassing it in?

The captain advised me to use pocket screws when I attached my coosa bulkhead to the cabin top, used a pocket screw drill guide to recess the screw heads a bit, I did this to get the entire bulkhead fastened, mixed up some thicken epoxy to set the bulkhead ,removed the temp screws ,used the same epoxy to glue the screws in place forever, made up a formed plastic spatula to create the fillet , I didn't use any cloth to attach the bulkhead to the top,just the above method ,both inside and outside, I used 2pieces of 1/2" coosa glued together with a mayonnaise consistency for the bulkhead fabrication, drove in a bunch of 1" wd40 coated drywall screws and fender washers to secure the coosa till it kicked off, been there a few years and lots of bumpy water, no cracks,on the inside and outside ,I troweled on a thickened coat of epoxy and went to the final finishing process

Who is online

Users browsing this forum: Bing [Bot], Google [Bot] and 377 guests