I found the info below at

http://www.repairengineering.com/shaft- ... ening.html. Does it look like good guidance to you? Also, what should I look for as indicators it's time to quit and take it to the machine shop for a pro to repair before I have to buy a new one...

Thanks,

Stephan

Spot Heat Shaft Straightening Method

What is the procedure to straighten a bent shaft using the Spot Heating method?

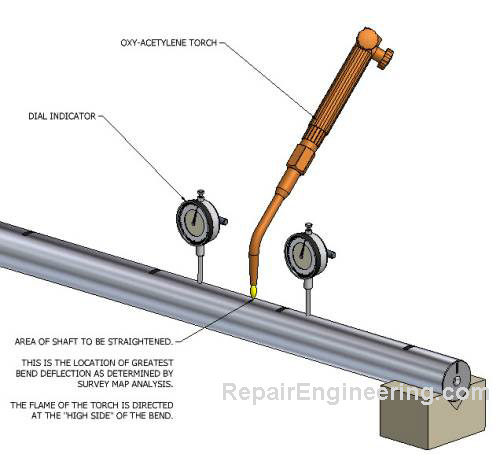

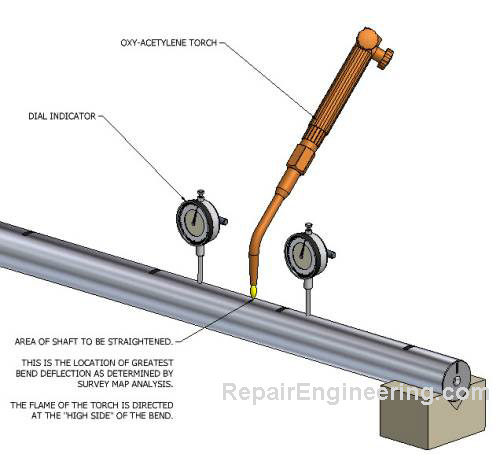

Figure 4. Typical spot heat shaft straightening set-up.

Procedure: 1.Create a Bent Shaft Survey Map to determine the location and amount of bend correction required. Rotate the shaft so that the "high side" of the bend with the greatest magnitude faces upward as shown in Figure 4. Part of the success of the spot heat shaft straightening method relies on the weight of the shaft itself to assist in correcting the bend.

2.Position dial indicators adjacent to the bend location as shown in Figure 4. If the shaft is supported between centers in a lathe, relax the center preload slightly so that the shaft can flex during the shaft straightening process without binding.

3.Working quickly, heat an area of the shaft about .5 in - 1 in. (12mm-25mm) diameter using the welding tip of an oxy-acetylene torch. The objective is to achieve a temperature differential, or local hot spot, between the area being heated and the surrounding area. Therefore, apply the heat evenly and steadily while monitoring the dial indicators.

It is really important to watch the dial indicators during the entire heating process as things will happen quickly, usually within several seconds.

As the shaft is heated, the dial indicators will climb - indicating that the amount of the bend is increasing, temporarily. This is the desired result, even though it seems counter-intuitive.

It is important to get a initial feel for the responsiveness of the shaft to bend reversal. During the first spot heating cycle, heat the shaft until the dial indicators show a thermal-caused deflection of three times the orginal bend.

Using the results from the first shaft straightening cycle, adjust the actual amount of indicated thermal deflection required on subsequent straightening cycles.

If this seems to be more art than science... it is.

Spot heating shaft straightening involves careful observation and educated trial-and error. However, it is generally possible to achieve good results by a methodical application of the process.

4.When the dial indicators show that the desired deflection is achieved, remove the heat and allow the shaft to cool. To speed-up the process, the cooling cycle can be accelerated by various methods such as pouring water on the shaft, or by the use of compressed air, a spray mist system, or by simply using a wet sponge or wet cloths.

If the shaft is straightened in a machine with a water-based flood coolant system, that can also be used to cool the shaft as shown here.

As the shaft is cooled, the dial indicators will move in the opposite direction as they did during the heating process. Continue cooling until the area that was heated is the same temperature as the rest of the shaft.

NOTE: Be sure to allow the shaft to cool completely prior to making measurements or further corrections because it will continue to move throughout the cool-down process.

5.After the cooling is complete, measure the magnitude of the bend that now exists in the area that was just straightened. Compare this new value with the previous bend deflection prior to the repair.

If no improvement in the bend is measured after the first repair cycle, repeat the spot heating process by increasing the heat-induced deflection in small increments of .010-.020 in (.25-.50 mm) more than used in the previous attempt.

NOTE: At any point, if the amount of heat required causes the shaft to become dull cherry red in color without having an effect on correcting the bend, the spot heating approach in unsuited as a repair method for that particular shaft and an alternate process needs to be used.

6.Repeat the process until the desired shaft straightness is obtained.

How does the spot heat shaft straightening process work, in principle?

Experienced welders are familiar with metal distortion, known as "drawing" or "heat affected zone", that occurs during the welding process. Spot heat shaft straightening uses the same principle. The mechanics of the process are as follows:

1.A small area is heated quickly so that the material in the localized area is in a softened, semi-plastic state while the surrounding material remains relatively cool and solid.

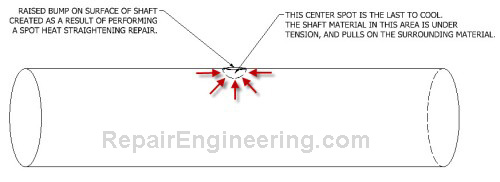

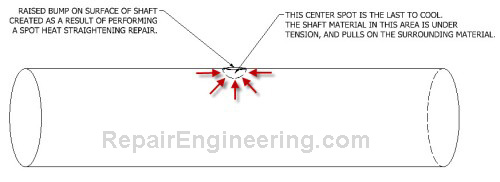

2.The spot-heated material expands as it is heated. Because the locally heated area is surrounded by solid (cooler) shaft material, the thermal expansion causes growth in the only unrestrained space available... toward the surface of the shaft. This expansion creates the raised bump on the surface of the shaft that is characteristic of the process.

3.As the shaft is cooled, it would be natural to assume that the material in the raised bump would return to its original state prior to heating. In actuality, the exposed surface of the bump cools the most quickly - and becomes solidified in the raised condition.

4.The very center of the heated spot is the last to cool and, as it cools, the material contracts. At this stage of the process, the center spot is surrounded on all sides by material that is in a cooler, solidified condition.

5.The contraction of the center creates a tensile stress at that location that is very close to the yield point of the material. The localized tensile stress exerts a force that pulls on the surrounding material and causes the shaft to deflect.

In Figure 5, the red lines indicate the shaft forces generated as a result of the localized area of tension. When performed properly, in the correct location, the tension forces can pull the shaft toward straightness.

Figure 5. Spot heated shaft.