Sound Down

Moderators: CaptPatrick, mike ohlstein, Bruce

Sound Down

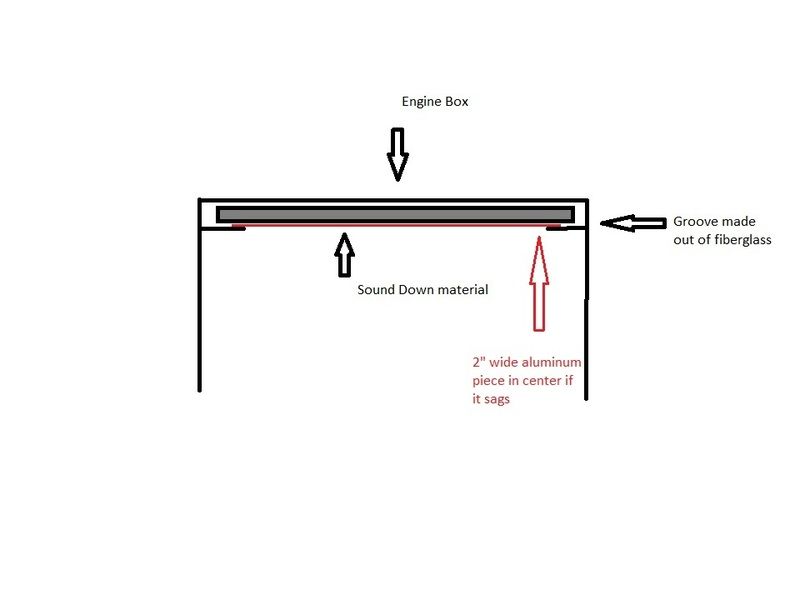

I have the materials and am ready to begin the installation process; I've read the instructions. Seems pretty straightforward, do any of you guys who've done it have any "pearls of wisdom" for installing Sound Down on my engine boxes? Searched the sandbox and found plenty of info about what to use, little discussion about the process. Any advice will be greatly appreciated. Thanks!

BRUISER

BERG1552M76F-315

Bradley Tiller

BERG1552M76F-315

Bradley Tiller

Re: Sound Down

I epoxied the nail things to the engine boxes in whatever spacing Soundown advised. As I remember, you push the Soundownl over the nail things, then the retainers over the nail things. You then cut off the ends of the nail things and push the round caps over the nail things. My tip--be careful when you cut the ends off the nail things, so that you cut them to the right length. I you leave them to long, the nail things will poke right through the round protecter caps, defeating the purpose of the caps, and will go right into your hand if you're aren't paying attention during the install. Not that this happened to me or anything...

1968 B20 Moppie - Hull # 201-937

1969 B31 FBC - Hull # 315-881 (sold)

1977 B31 FBC - Hull # BERG1652M77J

1969 B31 FBC - Hull # 315-881 (sold)

1977 B31 FBC - Hull # BERG1652M77J

Re: Sound Down

John F. wrote: I you leave them to long, the nail things will poke right through the round protecter caps, defeating the purpose of the caps, and will go right into your hand if you're aren't paying attention during the install. Not that this happened to me or anything...

LOL...pearls of wisdom right there!

If in doubt whether you have enough nail things to hold overhead panels...add two more for every one your not sure of.

Aside from that, watch out about leaving gaps in insulation...even the smallest openings allow lots of noise to spill out.

Re: Sound Down

I didn't have epoxy on hand when I did mine, but I did have poly resin and fiberglass. from the re-build.

I cut squares of 1708 (probably 4-5" on a side), stuck the nail thing through and positioned them in place.

I then went to each one with a chip brush and wetout the glass. I do not think I will have any issues with them coming loose.

Of course, proper surface preperation is a must.

Ian.

I cut squares of 1708 (probably 4-5" on a side), stuck the nail thing through and positioned them in place.

I then went to each one with a chip brush and wetout the glass. I do not think I will have any issues with them coming loose.

Of course, proper surface preperation is a must.

Ian.

Re: Sound Down

Thanks for the tips, I'll report on how it went.

BRUISER

BERG1552M76F-315

Bradley Tiller

BERG1552M76F-315

Bradley Tiller

Who is online

Users browsing this forum: Bing [Bot] and 73 guests