cutting a hole in starboard..need advice

Moderators: CaptPatrick, mike ohlstein, Bruce

cutting a hole in starboard..need advice

I am attempting to flush mount three guest battery switches in a sheet of 1/2 in starboard. Problem is I need a 5 1/8 hole saw. Looked around the web and dont see that size anywhere..any ideas?

One thought would be to use a rotary cut tool, dremmel or roto-zip or router, even a jig-saw would work. Use a compas or the battery switch to trace the line of the hole free hand the cut. If you can do this on the bench rather than installed it's not too bad. Hopefully there's a flange on the switch that will hide an irregular cut.

br,

JohnD

br,

JohnD

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

John,

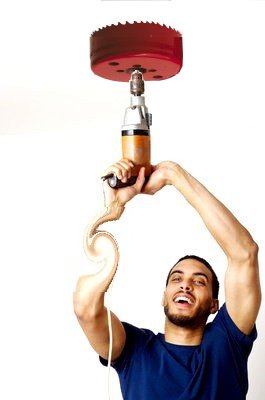

The easiest way is to use a 5" hole saw and then unch up the diameter with a 1 1/2" drum sander on your electric drill motor. If you wobble the hole saw a bit during the initial cut, the hole will be a tad bigger than 5" leaving only about 3/64" of radius to sand away, getting you to your desired diameter.

Br,

Patrick

The easiest way is to use a 5" hole saw and then unch up the diameter with a 1 1/2" drum sander on your electric drill motor. If you wobble the hole saw a bit during the initial cut, the hole will be a tad bigger than 5" leaving only about 3/64" of radius to sand away, getting you to your desired diameter.

Br,

Patrick

-

Raybo Marine NY

- Senior Member

- Posts: 895

- Joined: Jan 3rd, '07, 00:28

- Location: Lindenhurst, NY

- Contact:

-

steve miller

- Senior Member

- Posts: 157

- Joined: Aug 29th, '06, 21:40

- Location: block Island R.I.

- Contact:

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

-

Raybo Marine NY

- Senior Member

- Posts: 895

- Joined: Jan 3rd, '07, 00:28

- Location: Lindenhurst, NY

- Contact:

- In Memory of Vicroy

- Senior Member

- Posts: 2340

- Joined: Jun 29th, '06, 09:19

- Location: Baton Rouge, LA

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

John,

I've seen the HolePro and it ain't worth the hefty price they ask. The General brand Fly Cutters are usually under $15, available from most hardware stores and place like Home Dildo & Low's. They're almost bullet proof. The weak link is the hex key set screws which are small and round out after much use.

Br,

Patrick

I've seen the HolePro and it ain't worth the hefty price they ask. The General brand Fly Cutters are usually under $15, available from most hardware stores and place like Home Dildo & Low's. They're almost bullet proof. The weak link is the hex key set screws which are small and round out after much use.

Br,

Patrick

- In Memory of Vicroy

- Senior Member

- Posts: 2340

- Joined: Jun 29th, '06, 09:19

- Location: Baton Rouge, LA

Rawleigh - you musta made that word up for another 12 days of Christmas deal???? BTW, my fly cutter is indeed a General, very sturdy, made in the USA. I bought it at a gararge sale about 30 years ago for a buck, NIB. Another yard sale bought a gallon paint can full of stainless set screws, all sizes for a buck.

UV

UV

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

- CaptPatrick

- Founder/Admin

- Posts: 4161

- Joined: Jun 7th, '06, 14:25

- Location: 834 Scott Dr., LLANO, TX 78643 - 325.248.0809 bertram31@bertram31.com

-

Raybo Marine NY

- Senior Member

- Posts: 895

- Joined: Jan 3rd, '07, 00:28

- Location: Lindenhurst, NY

- Contact:

when we did a Bayhead it originally had teak covering boards, when we eliminated them we had to build the gunwale up, so in total the gunwale ended up close to 2" thick, drilling for a water fill I sent the milwaukee drill sideways which swung around and proceeded to smack me right on the chin.

All I kept thinking about was how lucky I was not to fall off the ladder, and how lucky I was that the side windows were not yet intalled because I would have went right through it.

All I kept thinking about was how lucky I was not to fall off the ladder, and how lucky I was that the side windows were not yet intalled because I would have went right through it.

best stuck tool i ever saw was a guy with a LARGE jack hammer held sideways from a steel beam by a chain. he was blasting a hole through a 12 '' thick concrete wall with a 16 inch stone chisel. the blade got stuck when it went all the way through. tttttuuuuurrrrrrnnnnnn iiiiiitttttt oooooofffffffffffffffffffffff.!!!!

John,

I took a different tack.

I got a bit slightly larger than the diameter of the switches. Cut the holes and mounted them centered in the larger holes (the screw-hole mounts are wider) which gave me air around the switches to cool them and to cool all the electronics behind the switches. Made a very interesting and functional application.

I took a different tack.

I got a bit slightly larger than the diameter of the switches. Cut the holes and mounted them centered in the larger holes (the screw-hole mounts are wider) which gave me air around the switches to cool them and to cool all the electronics behind the switches. Made a very interesting and functional application.

Mikey

3/18/1963 - -31-327 factory hardtop express, the only one left.

The difference between genius and stupidity is that genius has its limits.

-Albert Einstein

3/18/1963 - -31-327 factory hardtop express, the only one left.

The difference between genius and stupidity is that genius has its limits.

-Albert Einstein

Who is online

Users browsing this forum: Bing [Bot], Google [Bot] and 4 guests