I need to replace the synthetic (formica-ish) covering on the walls of 31s (in white) in one small exterior section.

The existing piece is curled and can best be used as a template.

Was this stuff actually Formica (Home Depot or Lowes) or was it something special ? .... what is best to use as an adhesive ?

thanks

formica

Moderators: CaptPatrick, mike ohlstein, Bruce

Re: formica

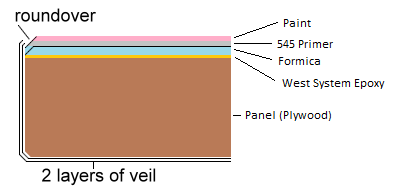

If you are referring to the cockpit side panels here is how I worked things out with Capt. Patrick's help:

CaptPatrick wrote:- Laminate Formica on to boards with West System (with some cabosil?).

- Trim up edges with laminate trimmer and seal end-grain of the boards with thickened epoxy.

Use enough Cabosil to make a mix the consistancy of mayonaise...

Use a round over bit to avoid 90 deg corners. Use a couple of layers of veil. Epoxy by itseft will shrink and crack down the road...

Possunt quia posse videntur

- Pete Fallon

- Senior Member

- Posts: 1313

- Joined: Jun 29th, '06, 23:10

- Location: Stuart Fl. and Salem, Ma.

Re: formica

Stephan.

If you are talking about the side and transom panels in the cockpit area of a 31' Bertram, try to get one of the local boat building companies,to lay up 3 pieces of 4'x10' sheets of 3/8" core mat with white gel coat on one side, the transom section has to be 10' x4' because its longer and wider than the side panels. The 2 side panels 4'x10' can be cut in half to make 2 panels port & starboard, the transom piece is wider and longer than the sides. The transom section is a little wider about 30" for the top curve and is about 110" long . The core mat will not delaminate or rot and the gel coated surface is easier to clean than Formica. The left over pieces can be used for other projects on the boat.

If you are talking about the side and transom panels in the cockpit area of a 31' Bertram, try to get one of the local boat building companies,to lay up 3 pieces of 4'x10' sheets of 3/8" core mat with white gel coat on one side, the transom section has to be 10' x4' because its longer and wider than the side panels. The 2 side panels 4'x10' can be cut in half to make 2 panels port & starboard, the transom piece is wider and longer than the sides. The transom section is a little wider about 30" for the top curve and is about 110" long . The core mat will not delaminate or rot and the gel coated surface is easier to clean than Formica. The left over pieces can be used for other projects on the boat.

1961 Express Vizcaya Hull 186 12-13-61

-

PaulJ

- Senior Member

- Posts: 123

- Joined: Jul 5th, '06, 11:51

- Location: Trapped at work planning my escape

Re: formica

Stephan,

I redid mine 5 years ago. For my cover boards, I just used high end marine ply (Okoume) from a local East-Central Florida company. This type of ply is used for making wooden boats that are stained/varnished to show the wood grain. So the finish is very smooth, but not quite Formica.

http://plywood.boatbuildercentral.com/p ... ume_BS1088

I used 9mm and doubled up the thickness around all of the boarders and cut-outs for added strength. The doubled up thickness was epoxied using West System with Cabosil. All fixture holes and attachment points were pre-drilled to ensure all edges would be sealed in the next step. Then everything was sanded, corners rounded over and 3 coats of West epoxy to seal in the wood.

I used Interlux Brightside single-part polyurethane and followed the roll-and-tip method. 3 coats of primer and 3 coats of the paint. It would take a well trained eye in a very low-profile light to find a brush stroke in the finish.

http://www.yachtpaint.com/usa/diy/produ ... thane.aspx

I had some custom Starboard hatches made with blind screw attachments by Buckwood Craft for the stud & port covers. Made for a very nice finish. I chose a grey Starboard which was a bit darker than the Seattle Graey color I picked for the paint. Nice contrast that blended well. http://www.buckwoodcraft.com/king-starb ... doors.html

They may not be as indestructible as the other ideas present here, but it was fairly easy to do, will last for as long as I will own the boat and look great.

Paul J

1973 B28 - PALADIN

I redid mine 5 years ago. For my cover boards, I just used high end marine ply (Okoume) from a local East-Central Florida company. This type of ply is used for making wooden boats that are stained/varnished to show the wood grain. So the finish is very smooth, but not quite Formica.

http://plywood.boatbuildercentral.com/p ... ume_BS1088

I used 9mm and doubled up the thickness around all of the boarders and cut-outs for added strength. The doubled up thickness was epoxied using West System with Cabosil. All fixture holes and attachment points were pre-drilled to ensure all edges would be sealed in the next step. Then everything was sanded, corners rounded over and 3 coats of West epoxy to seal in the wood.

I used Interlux Brightside single-part polyurethane and followed the roll-and-tip method. 3 coats of primer and 3 coats of the paint. It would take a well trained eye in a very low-profile light to find a brush stroke in the finish.

http://www.yachtpaint.com/usa/diy/produ ... thane.aspx

I had some custom Starboard hatches made with blind screw attachments by Buckwood Craft for the stud & port covers. Made for a very nice finish. I chose a grey Starboard which was a bit darker than the Seattle Graey color I picked for the paint. Nice contrast that blended well. http://www.buckwoodcraft.com/king-starb ... doors.html

They may not be as indestructible as the other ideas present here, but it was fairly easy to do, will last for as long as I will own the boat and look great.

Paul J

1973 B28 - PALADIN

- Bertramp

- Senior Member

- Posts: 1429

- Joined: Jan 2nd, '09, 14:57

- Location: Sag Harbor, NY Fort Lauderdale, FL

- Contact:

Re: formica

Pete & Paul ... thanks for the reply, but I believe that you are both referring to the cockpit side panels, I did those in AZAK and it worked great. I am referring to the Formica against the bulkhead, in my case (a Bahia) it is the bulkhead where you would enter the cabin ... probably same stuff that is on the door. The skinny piece to the outside of the helm let go and is curled up. You can't even really see it, but the bare ply just wont cut it, needs a covering in white to pretty much match.

Thanks

Thanks

1970 Bahia Mar - hull# 316-1003

1990 Blackfin 27 - center console

Steve "Bertramp" Kelly

1990 Blackfin 27 - center console

Steve "Bertramp" Kelly

- Pete Fallon

- Senior Member

- Posts: 1313

- Joined: Jun 29th, '06, 23:10

- Location: Stuart Fl. and Salem, Ma.

Re: formica

Steve,

Sorry for the communication problem, I had the Formica come loose around the entrance door (express) I was able to peel it back enough to access the old glue under the formica. Then I took a rag soaked in acetone jammed it under both to loosen the old glue on both pieces. Then I took a paint scrapper and removed the old glue, I did it a couple of times to get rid of all the glue. I put new Formica cement on both pieces and clamped it in place for 24 hours. The excess glue was scrapped off after it was completely dry. That was 10 years ago and it was still in place when I sold the boat in 2014.

Pete Fallon

Sorry for the communication problem, I had the Formica come loose around the entrance door (express) I was able to peel it back enough to access the old glue under the formica. Then I took a rag soaked in acetone jammed it under both to loosen the old glue on both pieces. Then I took a paint scrapper and removed the old glue, I did it a couple of times to get rid of all the glue. I put new Formica cement on both pieces and clamped it in place for 24 hours. The excess glue was scrapped off after it was completely dry. That was 10 years ago and it was still in place when I sold the boat in 2014.

Pete Fallon

1961 Express Vizcaya Hull 186 12-13-61

- bobfioresi

- Senior Member

- Posts: 134

- Joined: Jun 29th, '06, 13:28

Re: formica

I used versa board, bought it from riverhead building co. in east Hampton. I used 1/8" white. It is 1/2 the weight of azak, does not shrink or expand, and is paintable Cost is approx. 1/2 of azak. If your ever in Montauk,stop by jets marine on the corner next to uhleins my 31 express is in the yard in the back I used it on the cabin door panels , but not the doo r. did it about 4 years ago it cleans up great. comes in 4x8 sheets. still looks great

Who is online

Users browsing this forum: Google [Bot] and 83 guests