More from 07/01/02

Note first that the dates that appear throughout the index refer more to time periods rather than that specific date.

During this same period, the rudder shelf was produced and installed, the old engine beds were removed, the spaces cleaned up, the outboard shelves were re-designed, the old cabin bulkhead was removed, re-designed, and installed.

The image above is of the rudder shelf just about ready to be installed. Some of the images will continue to show how the shelf was constructed and installed.

The old Bertram rudder shelves are one of the main items to be replaced when doing a restoration. I don't think that I've ever seen an original set-up that wasn't in need of replacement, or at least some serious repairs...

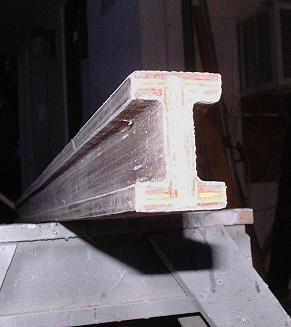

Here the rudder shelf has been fitted to the transom & the length has been adjusted to span fully between the outboard stringers.  The rudder shaft holes are piloted in from below and bored to 2" diameter. The rudder shaft will ride inside of a flange bearing and the hole will be covered by the bearing.  Using a long 3/8" drill bit and a couple of pieces of rubber tubing, a pilot drill that fits exactly into rudder port is produced.  The old mahogany plank joists that supported the deck on either side of the fuel tank were removed. In their place, I made "I" beams from 1/2" plywood and then encased them with 1708 biaxle fabric. The center of the beam is dadoed into the top and bottom pieces.  These I-beams will take up much less space and be just as strong as the original joists. |

In this view, the vertical support legs have been dadoed in and glassed into place. The legs ride inside of the inboard stringers  After a trial fit, the shelf has been gelcoated, faired and installed. The two outboard ends are bonded in and to be glassed to the outboard stringers. The support legs are through bolted to the stringers.  The idea is to keep the drill bit straight and parallel to the rudder shaft. Shoot all the way up and through the rudder shelf to create a pilot hole for the 2" hole saw.  The vertical support columns will be handled similar to the original Bertram columns, but with fresh material and epoxy coated.  Shelves were designed and installed outboard of the engine beds to be as low as possible. The top surface is even with the chine depression and run from bulkhead to bulkhead. These were done with plywood, glassed over with 1708 biaxle fabric and tabbed into the hull & bulkheads. |